Novel piperazine and homopiperazine derivative and preparation method and use thereof

A technology of piperazine and compound, applied in the field of pharmaceutical compositions containing the above substances, can solve problems such as poor water solubility, limited clinical application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

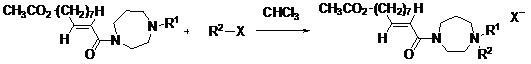

Method used

Image

Examples

Embodiment 1

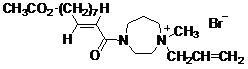

[0108] Example 1: 1-methyl-4-(10-acetoxy-2-decenoyl) piperazine (compound 1 ) preparation

[0109] Step 1: Preparation of 10-acetoxy-2-decenoic acid

[0110]

[0111] Under stirring conditions, 10-hydroxy-2-decenoic acid (9.30 g, 50 mmol) and acetic anhydride (9.43 mL, 100 mmol) were successively added to a 50 mL dry round-bottomed flask, and the above mixture was added at 100 ° Heat to reflux in C oil bath for 1 h. The reaction solution was concentrated under reduced pressure, and the obtained crude product was subjected to silica gel column chromatography (eluent: V 丙酮 : V 石油醚 = 1:20) separation and purification to obtain 9.51 g of pale yellow oily liquid with a yield of 83.4%.

[0112] Step 2: 1-methyl-4-(10-acetoxy-2-decenoyl) piperazine (compound 1 ) preparation

[0113]

[0114] 1

[0115] 10-Acetoxy-2-decenoic acid (2.28 g, 10 mmol) and dichloromethane (30 mL) were added to a 50 mL round bottom flask, and SOCl was added dropwise with stirring 2 (1.46 m...

Embodiment 2

[0116] Example 2: 1-ethyl-4-(10-acetoxy-2-decenoyl)piperazine (compound 2 ) preparation

[0117] 2

[0118] The method was the same as that of the intermediate example 1, and ethylpiperazine was substituted for methylpiperazine to obtain 5.56 g of light yellow oily liquid with a yield of 85.8%. 1 H NMR (CD 3 OD, 500 MHz) δ : 6.86~6.70 (m, 1H, C H =CHCO), 6.45 (d, J =14.9 Hz, 1H, CH=C H CO), 4.07 (t, J =6.7 Hz, 2H, OC H 2 –(CH 2 ) 5 –CH 2 ), 3.68 (t, J =5.0 Hz, 4H, (C H 2 ) 2 NC 2 h 5 ), 2.55~2.45 (m, 6H, CON(C H 2 ) 2 and NC H 2 CH 3 ), 2.30~2.24 (m, 2H, OCH 2 –(CH 2 ) 5 –C H 2 ), 2.05 (s, 3H, C H 3 CO 2 ), 1.68~1.35 (m, 10H, OCH 2 –(C H 2 ) 5 –CH 2 ), 1.14 (t, J =7.2 Hz, 3H, NCH 2 C H 3 ); 13 C NMR (CD 3 OD, 125MHz) δ : 171.6, 166.3, 146.8, 119.9, 64.3, 52.7, 52.1, 51.8, 45.2, 41.5, 32.1, 28.8, 28.7, 28.6, 28.3, 25.6, 19.7, 10.7; ESI-MS m / z : 325.23 (M+1) + ; IR (KBr, cm –1 ) ν: 1738 (C=O), 1659 (C=O), 1...

Embodiment 3

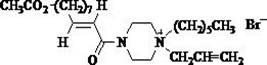

[0119] Example 3: 1-hexyl-4-(10-acetoxy-2-decenoyl)piperazine (compound 3 ) preparation

[0120] 3

[0121] Method is the same as intermediate embodiment 1, and hexylpiperazine is replaced methylpiperazine, and the thick product of gained is with silica gel column chromatography (eluent: V 甲醇 : V 乙酸乙酯 =1:2) separation and purification to obtain 5.92 g of light yellow oily liquid with a yield of 77.8%. 1 H NMR (DMSO- d 6 , 500 MHz) δ : 6.69~6.10 (m, 1H, C H =CHCO), 6.44 (d, J =15.0 Hz, 1H, CH=C H CO), 4.06 (t, J =6.6 Hz, 2H, OC H 2 –(CH 2 ) 5 –CH 2 ), 3.55~3.45 (m, 4H, (C H 2 ) 2 N(CH 2 ) 5 CH 3 ), 2.35~2.23 (m, 6H, CON(C H 2 ) 2 and NC H 2 –(CH 2 ) 4 –CH 3 ), 2.21~2.14 (m, 2H, OCH 2 –(CH 2 ) 5 –C H 2 ), 2.00 (s, 3H, C H 3 CO 2 ), 1.60~1.22 (m, 18H, OCH 2 –(C H 2 ) 5 –CH 2 and NCH 2 –(C H 2 ) 4 –CH 3 ), 0.87 (t, J =6.5 Hz, 3H, NCH 2 –(CH 2 ) 4 –C H 3 ); 13 C NMR (DMSO- d 6 , 125MHz) δ : 170.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com