Method for purification of ascomycin from streptomyces fermentation liquid

A technology of ascomycin and streptomyces, applied in the field of bioengineering, can solve the problems of market occupation, affecting product purity and product form, and high separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

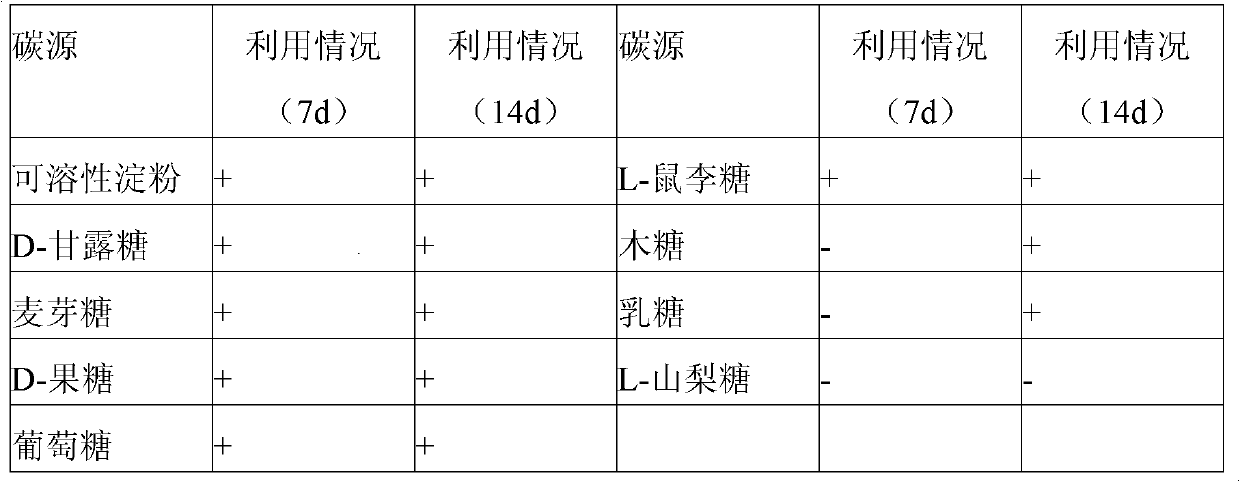

Image

Examples

Embodiment 1

[0043] 1) Filtrate the Streptomyces CGMCC No.2519 fermentation broth, and collect the filtrate and mycelia respectively. The mycelium was extracted 3 times by ultrasound, the organic solvent used in the ultrasound-assisted extraction was methanol, the mass volume ratio (g / ml) of mycelia to methanol was 1:15, the ultrasonic frequency was 45KHz, the power was 120W, the For 30 minutes, the pH of the system was 6.5, the extract was collected and combined with the filtrate to obtain the combined solution;

[0044] 2) After the combined liquid obtained in step 1) is filtered through the microfiltration membrane, the permeated liquid of the microfiltration enters the ultrafiltration membrane for filtration to obtain the filtrate, which is transferred to the bed layer equipped with SP207 macroporous resin for adsorption; Wash with 60% ethanol of the column bed volume of the macroporous resin, desorb with ethyl acetate of 1 times the column bed volume of the macroporous resin, and coll...

Embodiment 2

[0050] 1) Filtrate the Streptomyces CGMCC No.2519 fermentation broth, and collect the filtrate and mycelia respectively. The mycelium was extracted 4 times with ultrasonic assistance, the organic solvent used in the ultrasonic-assisted extraction was ethyl acetate, the mass-volume ratio (g / ml) of mycelium to ethyl acetate was 1:10, the ultrasonic frequency was 35KHz, and the power was 180W , the ultrasonic extraction time is 15 minutes, the pH of the system is 7, the extract is collected, combined with the filtrate to obtain the combined solution;

[0051] 2) After the combined solution obtained in step 1) is filtered through the microfiltration membrane, the microfiltration permeate enters the ultrafiltration membrane for filtration to obtain the filtrate, which is transferred to the bed layer equipped with SP825 macroporous resin for adsorption; Wash with 55% methanol of the column bed volume of the macroporous resin, desorb with acetone twice the volume of the column bed of...

Embodiment 3

[0057] 1) Filtrate the Streptomyces CGMCC No.2519 fermentation broth, and collect the filtrate and mycelia respectively. The mycelium is extracted 5 times by ultrasonic wave. The organic solvent used in the ultrasonic wave-assisted extraction is ethanol. For 45 minutes, the pH of the system was 7.5, the extract was collected and combined with the filtrate to obtain the combined solution;

[0058] 2) The combined solution obtained in step 1) is filtered through the microfiltration membrane, and the permeate of the microfiltration enters the ultrafiltration membrane for filtration to obtain the filtrate, which is transferred to the bed layer equipped with D101 macroporous resin for adsorption; Wash with 50% ethanol of the column bed volume of the porous resin, desorb with methanol of 3 times the volume of the column bed of the macroporous resin, and collect the desorption liquid at the temperature of the column bed at 30°C;

[0059] 3) The desorption solution collected in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com