Rubber cladding layer for cylinder of conveyor and preparation method thereof

A rubber coating, acid and alkali resistant technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problem of unsolved rollers, etc., and achieve the effect of high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1~6

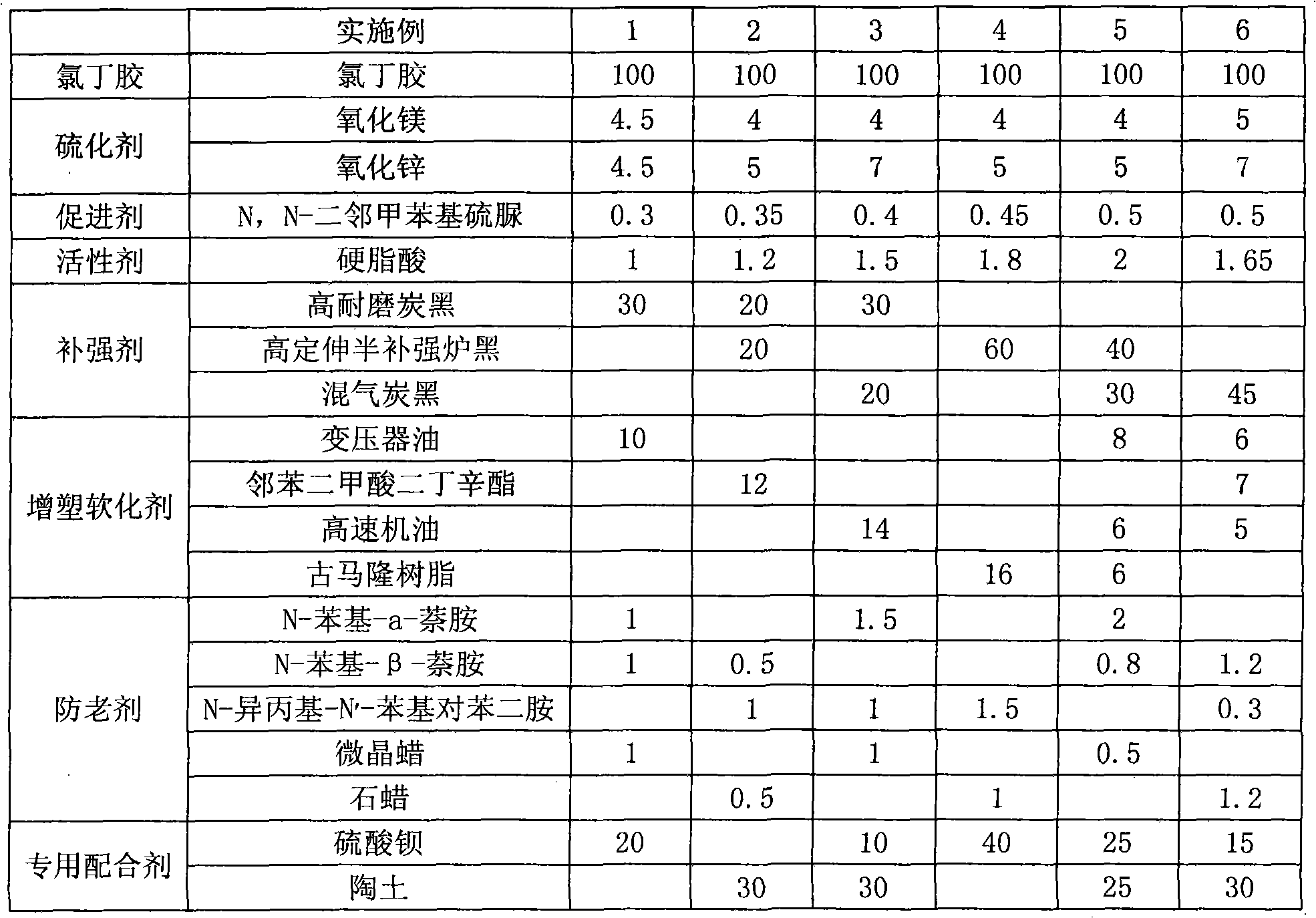

[0029] The acid and alkali resistant rubber cladding layer material in Experimental Examples 1 to 6 is an acid and alkali resistant rubber material with neoprene as the main body, including neoprene, vulcanizing agent, accelerator, active agent, reinforcing agent, plasticizer and softener , anti-aging agent and special compounding agent; the specific components and corresponding dosages of experimental examples 1 to 6 are shown in Table 1;

[0030] Components and consumption (kg) of table 1 embodiment 1~6

[0031]

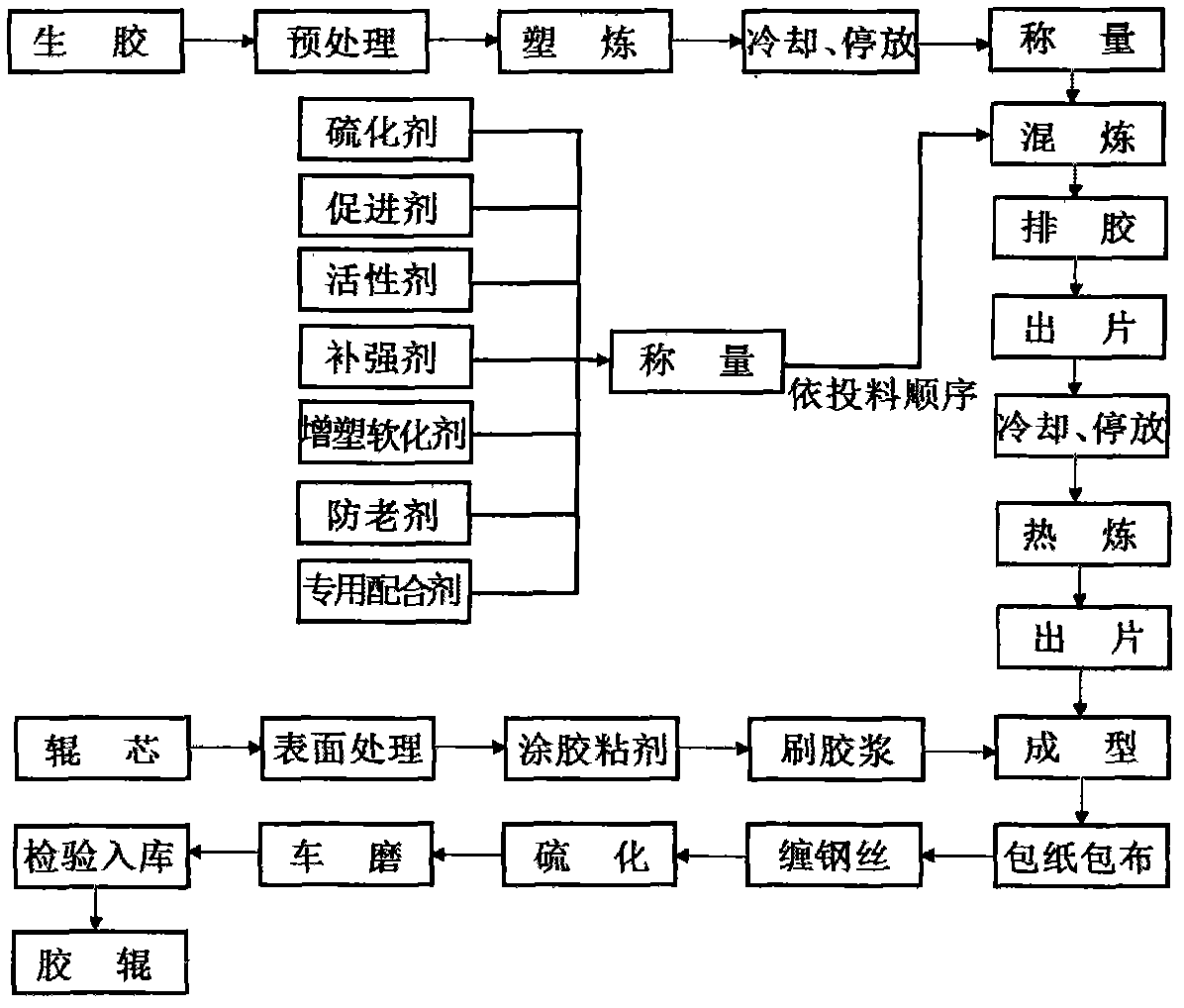

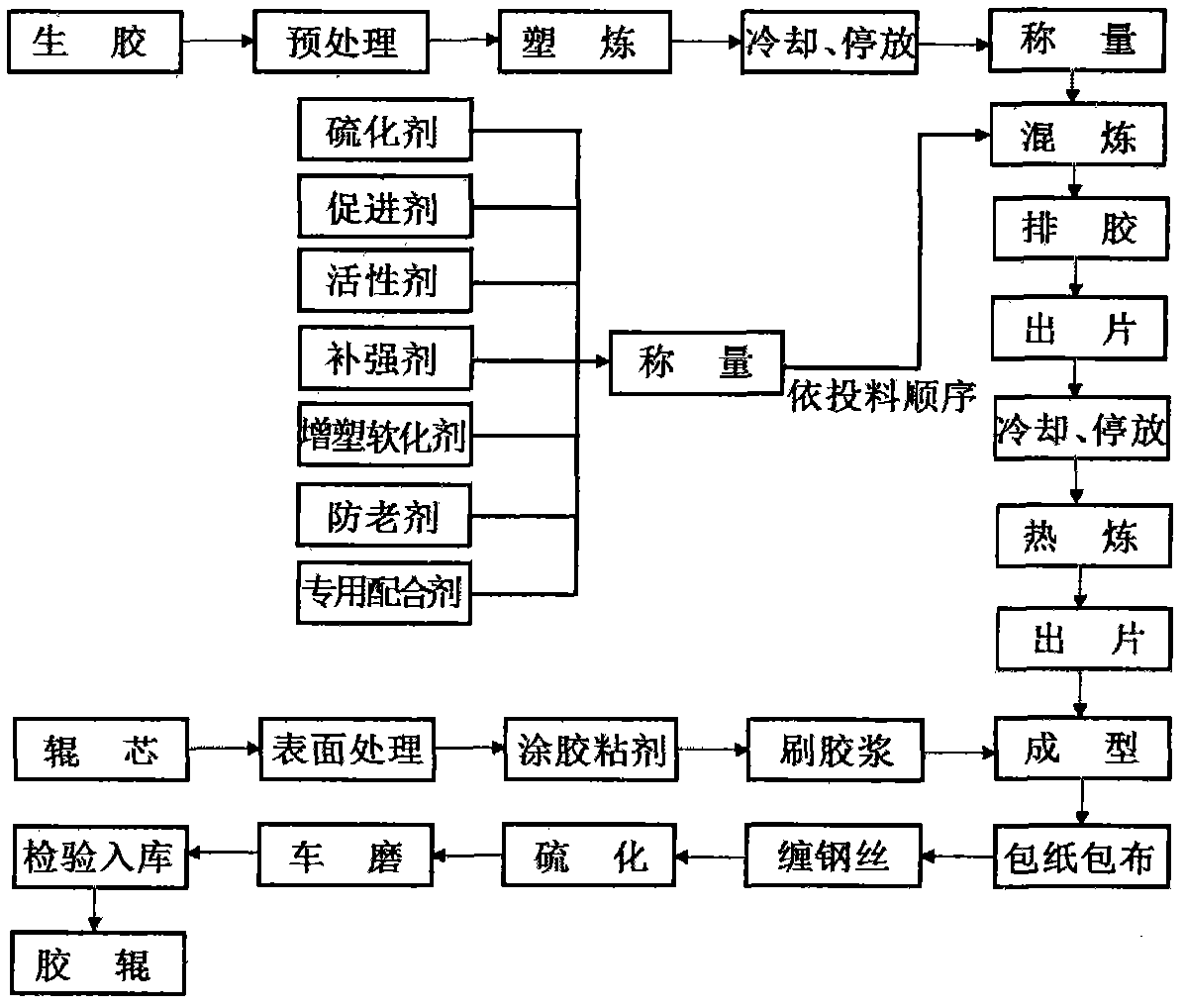

[0032] Such as figure 1 As shown, using the above-mentioned acid and alkali resistant rubber coating layer material to prepare the roller rubber coating layer includes the following steps:

[0033] A. Using neoprene as the main material, when preparing the rubber material for the rubber coating layer of the roller, the material is firstly pretreated, and then the neoprene is masticated. Chloroprene plasticizing method: roll temperature 30-35°C, pass 4 times wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com