Adjustable guide vane system of gas turbine power turbine

A technology for power turbines and gas turbines, which is used in the lubrication of turbine/propulsion devices, engine components, and engine lubrication. The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

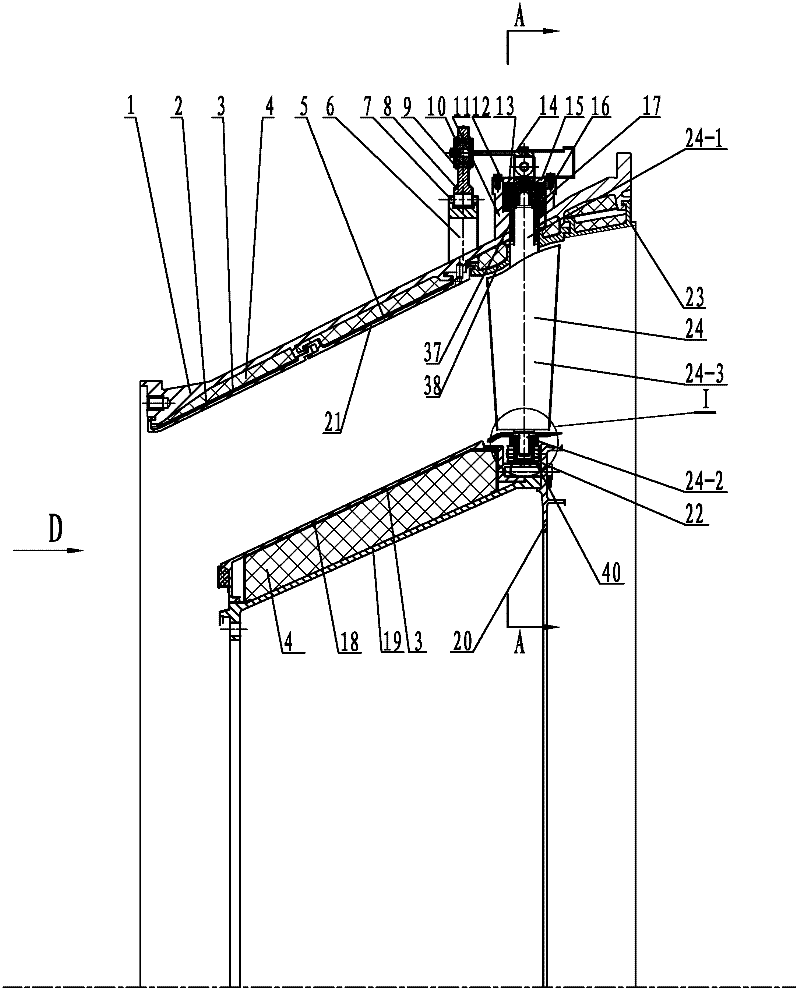

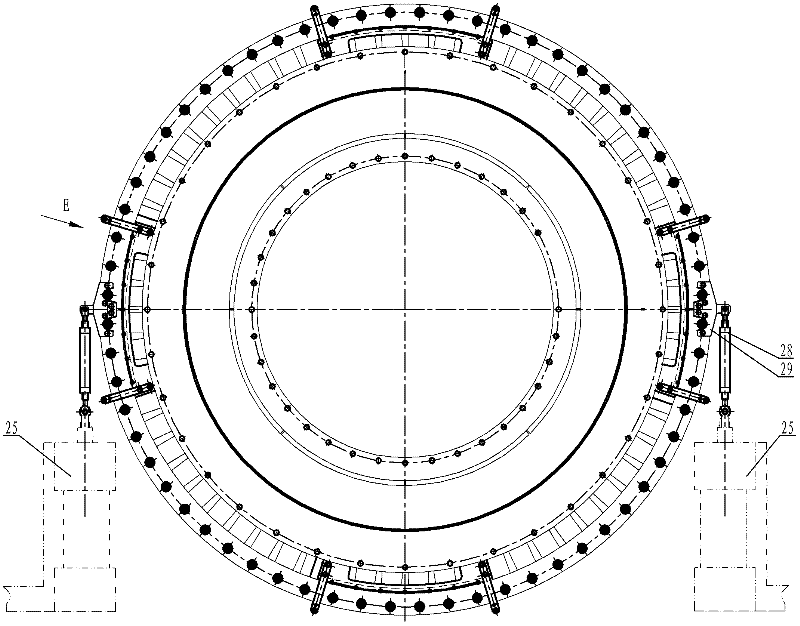

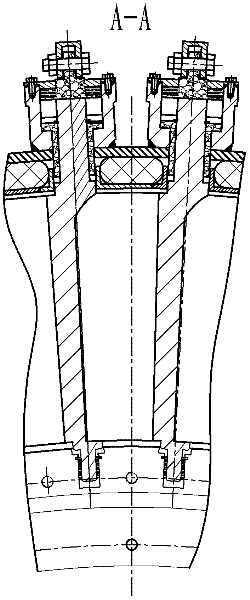

[0009] Specific implementation one: as Figure 1~6 As shown, the gas turbine power turbine steerable vane system of this embodiment includes a casing 1, a front outer casing 2, a first steel belt 3, a second steel belt 21, a rear outer casing 5, a guide rail 6, a roller 7, a linkage Ring 8, retaining spring 9, first bearing sleeve 10, second bearing sleeve 11, ceramic shaft 12, rocker arm 14, end cover 15, inner casing 18, adapter tube 19, flange 20, retaining ring 23, optional Guide vane 24, ball bearing 33, dial 35, pointer 36, ceramic bushing 37, guard plate 38, left half cylinder 39, flexible graphite bushing 40, right half cylinder 42, two forks 29, two elastics 28, two actuators 25 and a plurality of silicate fiber needled felt layers 4, the first steel belt 3 is installed on the upper end surface of the front housing cover 2, and the second steel belt 21 is installed on the rear housing On the upper end surface of the cover 5 , the front outer cover 2 , the rear outer ...

specific Embodiment approach 2

[0010] Specific implementation two: as figure 1 and Figure 5 As shown, the turbine rotatable guide vane system in this embodiment further includes a graphite gasket 13 , and the graphite gasket 13 is located between the end cover 15 and the ceramic shaft 12 . In this way, the flexible graphite gasket 13 reduces the loss of gas leakage caused by the rotatable guide vanes, and ensures that the operating performance of the gas turbine part under non-design conditions is greatly improved and the operation is safer. Other components and connection methods are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation three: as figure 1 As shown, the turbine rotatable guide vane system in this embodiment further includes a first gasket 16 , and the first gasket 16 is located between the end cover 15 and the second bearing sleeve 11 . Other compositions and connection methods are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com