Preparation method of TEM (Transmission Electron Microscopy) sample

A sample and sample technology, which is applied in the field of TEM sample preparation, can solve the problems of unclear contact hole pattern and inability to accurately observe the contact hole shape, and achieve the effect of easy observation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

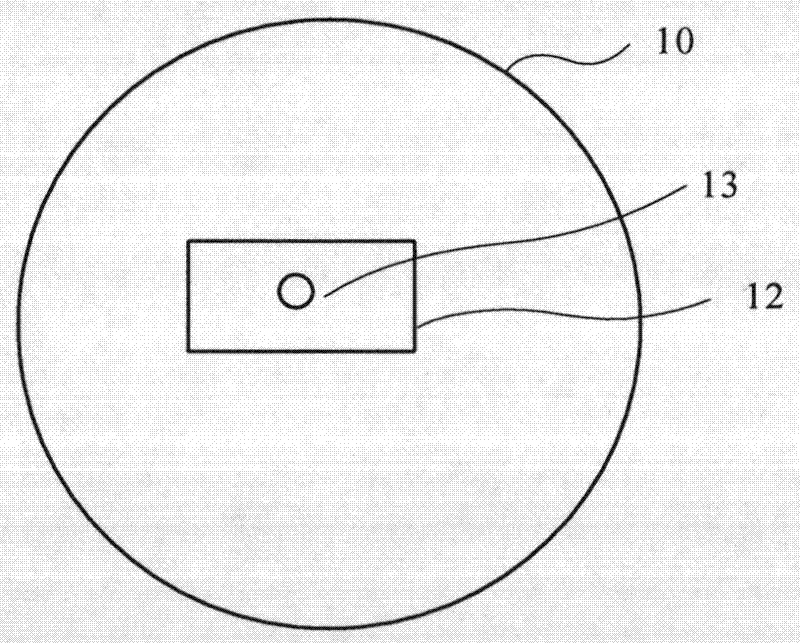

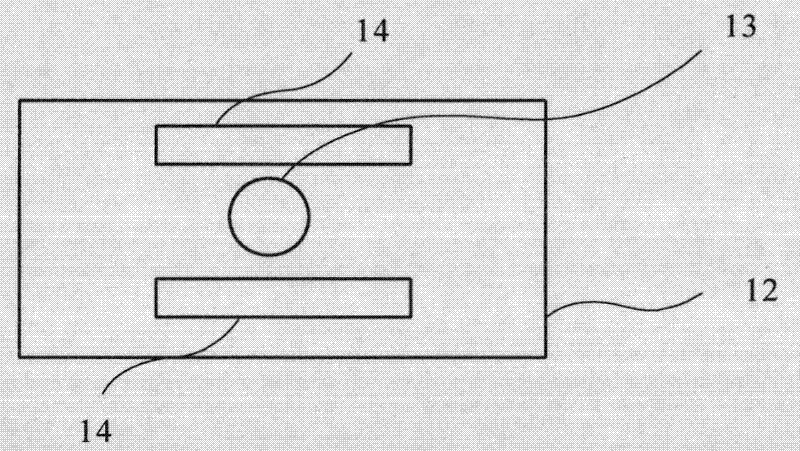

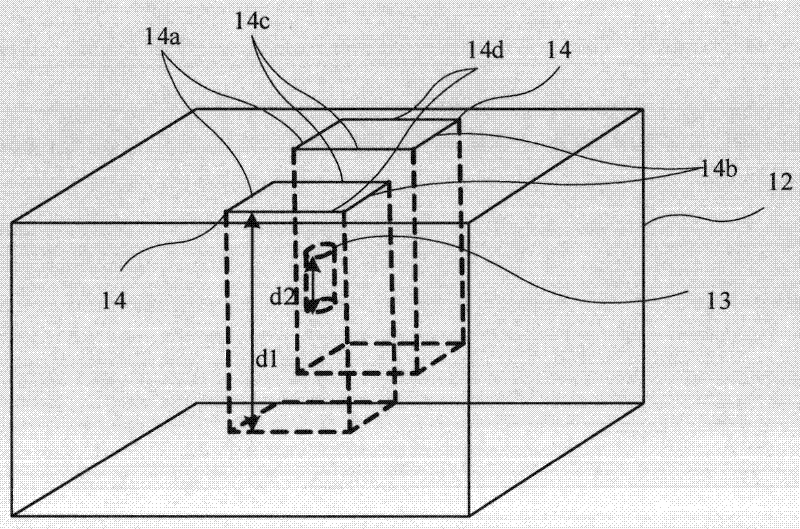

[0035] Figure 5 It is a flowchart of the preparation method of the TEM sample of the present invention. Such as Figure 5 Shown, the preparation method of TEM sample of the present invention comprises steps:

[0036] S10, providing a test sample, the test sample has a contact hole and a metal layer on both sides of the contact hole, and the metal layer is connected to the filling metal in the contact hole through a metal connection;

[0037] S20, cutting out a sample from the test sample, the sample including the contact hole, the metal wiring and the metal layer;

[0038] S30, forming pits on both sides of the contact hole, the metal interconnection and the metal layer on the front surface of the sample, the pit having an opposite surface opposite to the contact hole, the metal interconnection and the metal layer;

[0039] S40, thinning the thickness of the area where the contact hole and part of the metal wiring of the sample are located from the opposite surface of the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com