Device for testing damp-heat aging of composite material

A technology of damp heat aging and test equipment, which is applied in the direction of material inspection products, etc., can solve the problems of accelerated damp heat aging, etc., and achieve the effects of easy operation, improved test efficiency, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with example the present invention is described in detail.

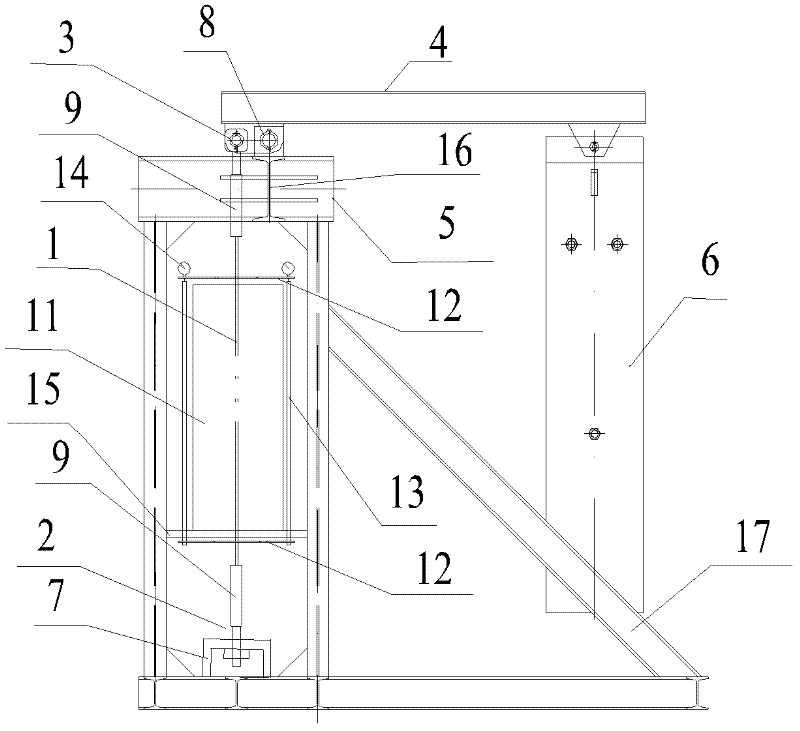

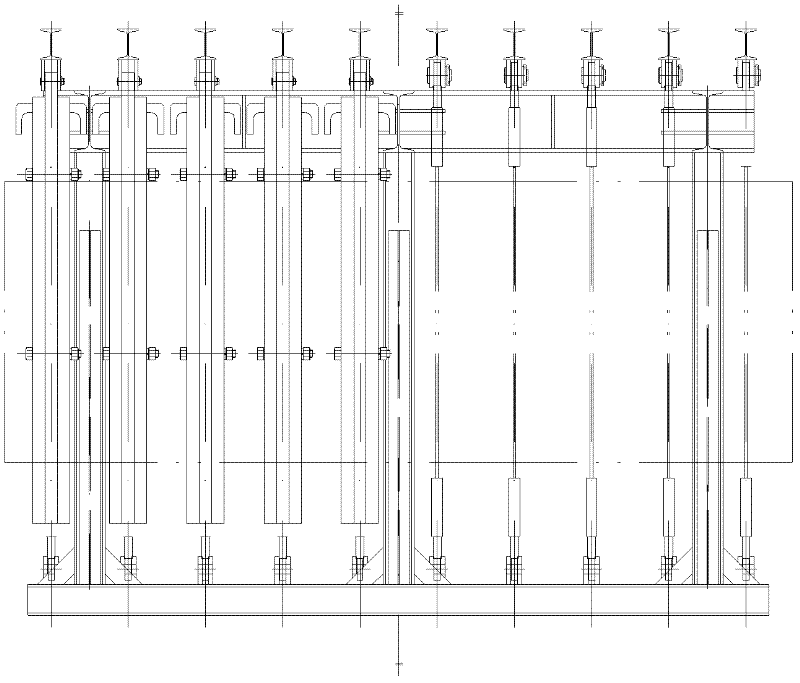

[0036] Aiming at the technical defect of the existing single thermal factor aging equipment, the present invention processes and manufactures a set of accelerated thermal aging test equipment capable of realizing multi-station, mechanical type and loadable stress. The equipment mainly consists of steel frame 5, balance beam 4, counterweight 6, temperature and humidity control system, humidity control system, stress and strain measurement structure, and balance adjustment system.

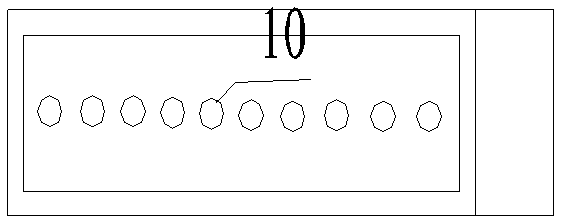

[0037] The temperature and humidity control system mainly includes an aging box 11. The aging box 11 is divided into a temperature and humidity control area and a heating and humidifying area. The upper and lower ends of the aging box 11 are provided with coaxial through holes 10 for the passage of the sample 1. During the test, first pass the sample 1 through the through hole 10 of the aging box 11 , and then fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com