Method for predicating overdying formula of colored fabric

A prediction method and fabric technology, applied in color measurement devices, special data processing applications, instruments, etc., can solve the problems of underutilized color matching functions of color matching software, and achieve improved accuracy, simple process, and improved color matching speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

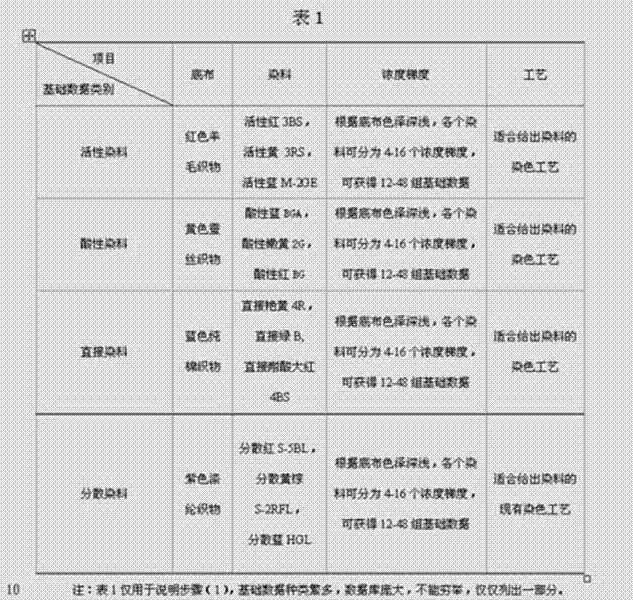

[0042] 1) Establish a basic database including the base fabric data of colored fabrics, and the basic color sample data of various dyes dyeing colored fabrics in different concentrations and gradients: Table 1 shows examples of the basic database forms. The basic color sample in the basic database in the step 1) is the apparent depth obtained by dyeing colored fabrics with different concentration gradients of various dyes, namely:

[0043] ①

[0044] In the formula: K represents the absorption coefficient of the tested fabric; S represents the scattering coefficient of the tested fabric; (K / S) m Indicates the apparent color depth of the target colored fabric; (K / S) t Indicates the apparent color depth of colored fabrics; c i "Indicates the dye concentration on the dyed fabric on each dye; k i ˊ represents the concentration of each dye unit on the colored fabric K / S value. Where (K / S) m ( Indicates the apparent color depth of the target colored fabric) and ...

Embodiment 2

[0050] The main steps of this embodiment are the same as in Example 1, the difference is that: the colored plain cotton poplin base fabric is adopted, and the colored plain cotton poplin is dyed by direct red D / BLL, direct navy blue D-R and direct yellow D / 3RNL, and the dyestuff is used for fabric dyeing. The weight percentages are 0.1%, 0.5%, 1%, 1.5%, 2%, 4% respectively, the dosage of sodium sulfate is 15g / L, and the bath ratio is 1:30. Dyeing is started at 30°C, and after 10 minutes of heat preservation, sodium sulfate is added. Raise the temperature to 90°C at 3°C / min, keep it warm for 60 minutes, wash with water, and then fix the color. Fixing formula: 1% color fixing agent, 1% acetic acid, time 15min, temperature 50℃, liquor ratio: 1:30.

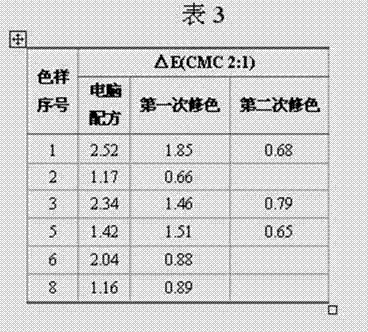

[0051] In the same way: the colored plain cotton poplin base fabric and dyed samples are tested by a color matching instrument and then input into the computer to establish a basic database, randomly select 6 target color samples, pre...

Embodiment 3

[0053] The main steps of this embodiment are the same as in Example 1, the difference is that: the colored plain cotton poplin base fabric is adopted, and reactive red 3BS, reactive yellow 3RS and reactive blue M-2GE are used to dye the colored plain cotton poplin, and the weight percentage of the dyestuff to the fabric Respectively 0.1%, 0.5%, 1%, 1.5%, 2%, 4%, the dosage of sodium sulfate is 40g / L, soda ash: 10g / L, liquor ratio 1:30. Dyeing is started at 30°C, and added after 10 minutes of heat preservation For Yuanmingfen, heat up to 60°C at 2°C / min, add half of the soda ash, add the other half of soda ash after 10 minutes of heat preservation and dyeing, wash with water after 40 minutes of heat preservation and dyeing, and then wash with water. Soaping method: soaping agent 2g / L, soda ash 1g / L, soaping at 90°C for 15 minutes, liquor ratio 1:30.

[0054] The colored plain cotton poplin base fabric and the dyed samples are tested by a color matching instrument and input into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com