Virtual monitoring method for transformer substation sequence control

A substation monitoring and sequence control technology, applied in the direction of electrical components, circuit devices, information technology support systems, etc., can solve the problems of increasing system complexity and maintenance difficulty, reducing operation reliability and system stability, etc., to improve equipment availability Maintainability and operational reliability, achieve unmanned duty, reduce labor and operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

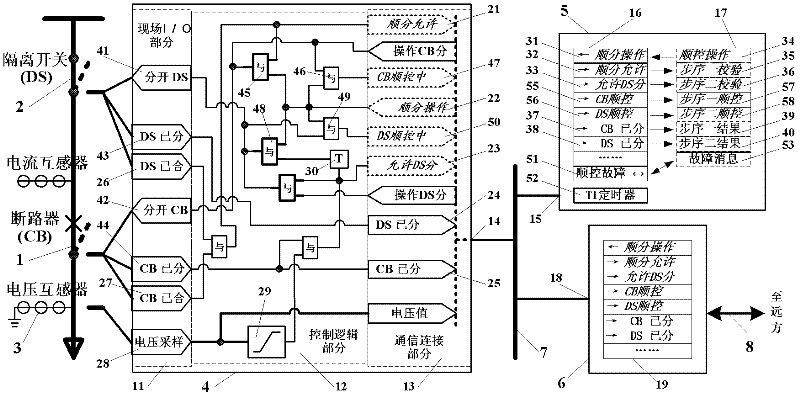

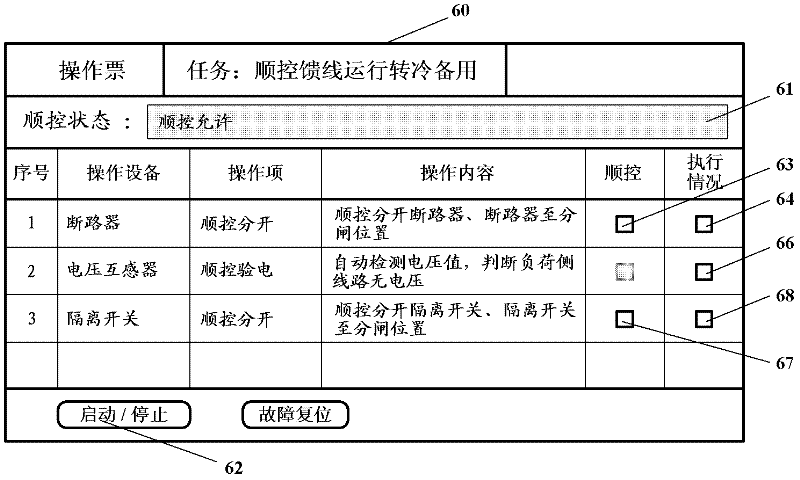

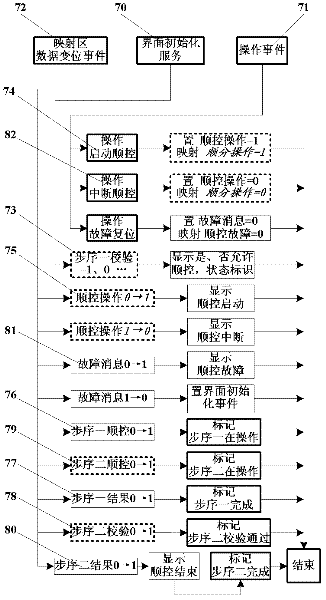

[0028] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0029] Sequential control is an automatic operation mode in which intelligent equipment simulates manual operation processes and steps, combined below figure 1 Introduce the content and steps of manually operating the primary equipment group (circuit breaker 1, disconnector 2) in order to remove the load of the normal power supply feeder:

[0030] State before operation: circuit breaker 1 and isolating switch 2 are both in the closing position, confirm that there are two operations;

[0031] The first operation: disconnect the circuit breaker 1;

[0032] The second step is to check before operation (avoid the anti-misoperation inspection of the disconnecting switch with load): check that the status indication of circuit breaker 1 is disconnected, check that there is no voltage on the load side line of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com