Ceramic multilayer substrate producing method

A technology of multilayer substrate and manufacturing method, which is applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, and electric recording technology using charge patterns, etc., can solve the problem of surface electrodes such as ceramic multilayer substrates, and achieve the suppression of migration intensification, Effect of preventing short circuit between electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

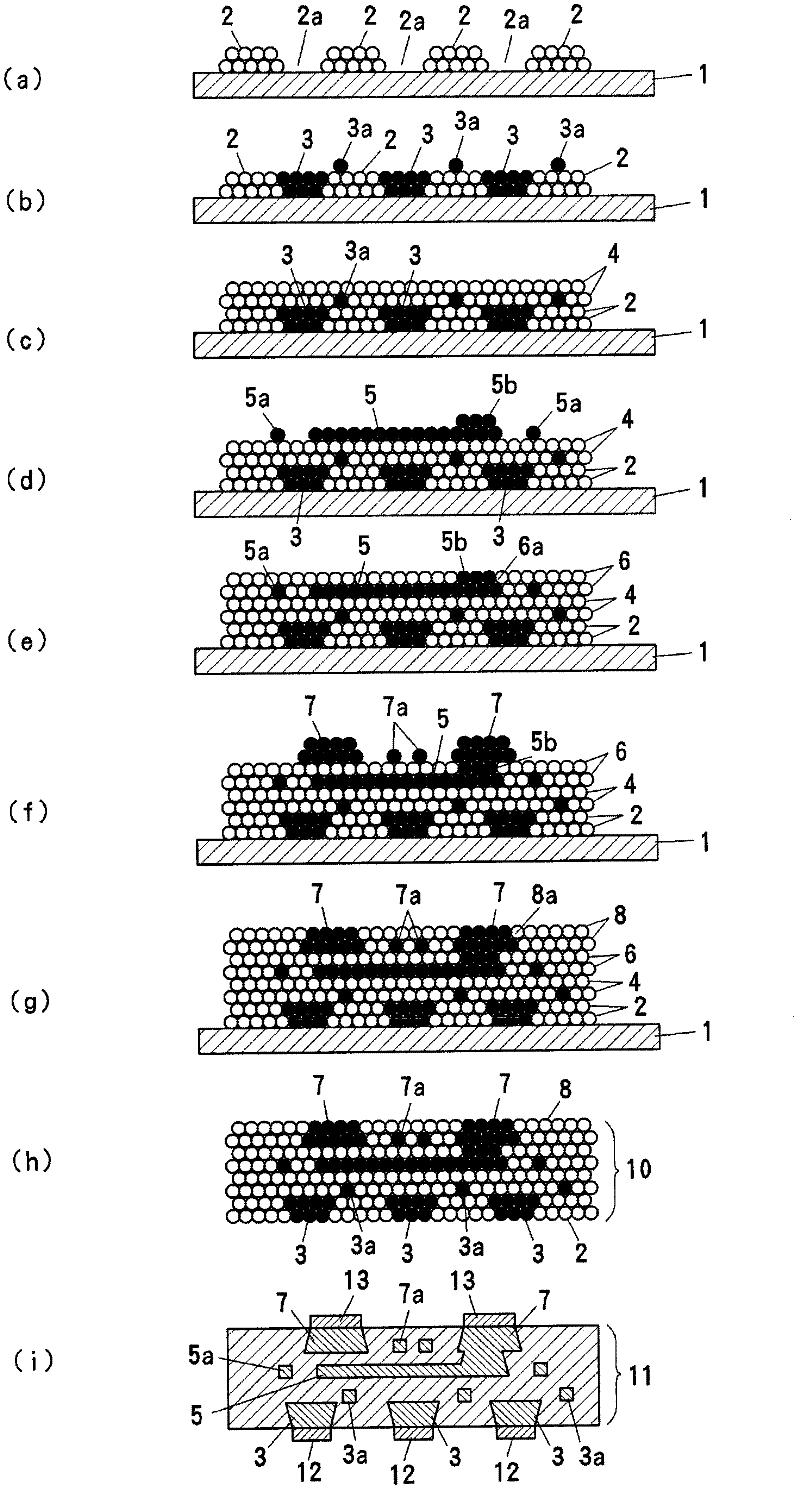

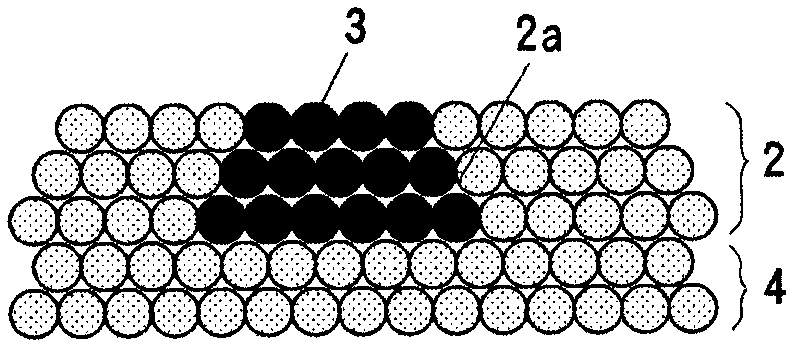

[0036] figure 1 Embodiment 1 which shows the manufacturing process of a ceramic multilayer board|substrate. This embodiment relates to a method of forming both the ceramic layer and the electrode using electrophotography as a method of directly forming the ceramic layer and the electrode on the carrier member (direct transfer method). Hereinafter, the manufacturing process will be described in the order of lamination.

[0037] figure 1 (a) shows the state where the outer layer ceramic layer 2 is formed on the carrier member 1 by electrophotography using a ceramic toner (charged powder for forming a ceramic layer). The carrier member 1 may be a resin film having heat resistance above the fixing temperature, such as a PET film, or may be a thin metal plate. On the outer ceramic layer 2, an opening 2a having the same size as a surface electrode to be formed later is formed.

[0038] One example of a specific method of forming the ceramic layer 2 is as follows.

[0039] (1)...

Embodiment approach 2

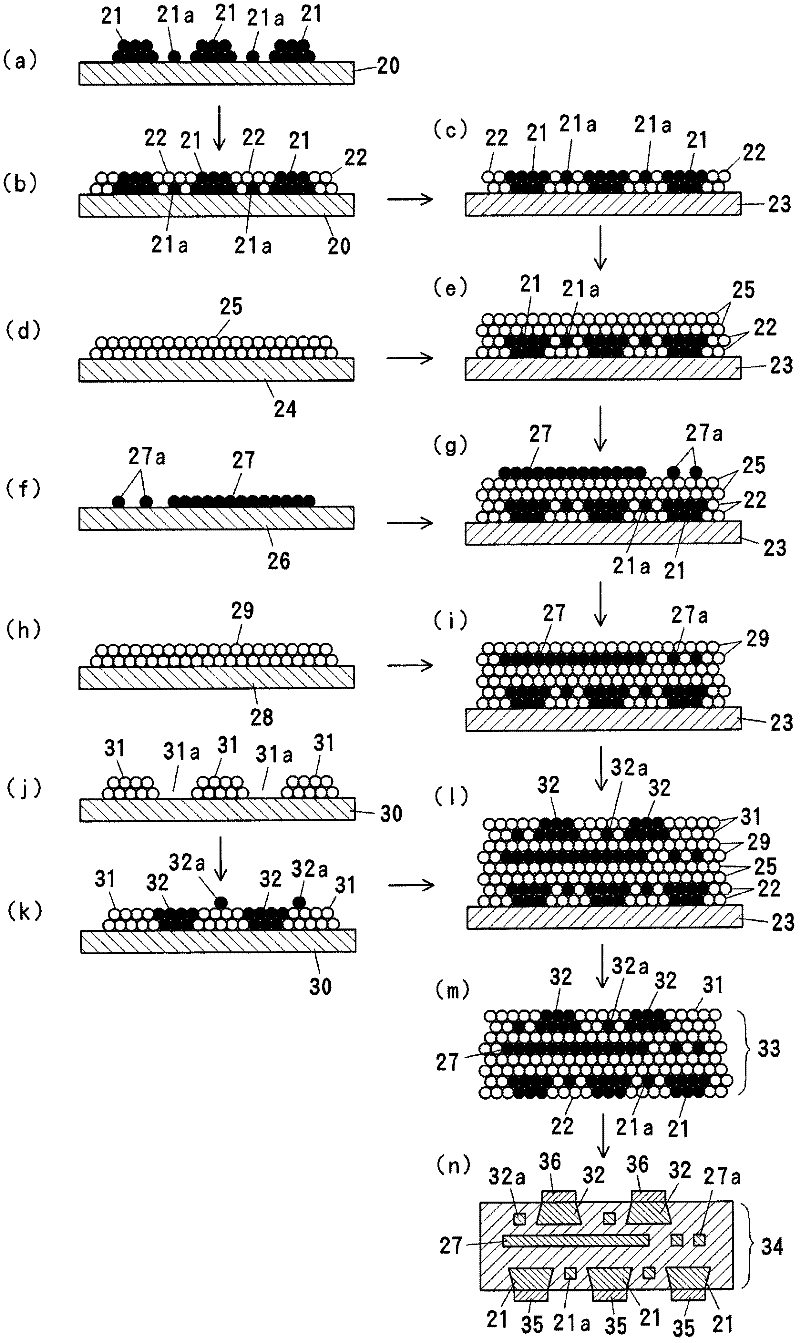

[0092] image 3 Embodiment 2 which shows the manufacturing process of a ceramic multilayer board|substrate. This embodiment relates to a method of forming both a ceramic layer and an electrode using an electrophotography method as a method of transferring a ceramic layer and an electrode onto a carrier member using an intermediate transfer body (intermediate transfer method). Hereinafter, the manufacturing process will be described in the order of lamination.

[0093] image 3 (a) shows the state where the surface electrode 21 was formed on the intermediate transfer body (for example, PET film) 20 using the electrode toner by electrophotography. Here, the exposure toner 21 a generated near the surface electrode 21 runs onto the intermediate transfer body 20 . The method of forming the surface electrodes 21 and the material of the electrode toner are the same as those in the first embodiment.

[0094] image 3 (b) shows the state where the outer layer ceramic layer 22 is f...

Embodiment approach 3

[0109] Figure 4 Embodiment 3 of the manufacturing method of a ceramic multilayer substrate is shown. This embodiment relates to a method using a ceramic green sheet as a method of directly forming a ceramic layer and an electrode on a carrier member (direct transfer method). Hereinafter, the manufacturing process will be described in the order of lamination.

[0110] Figure 4 (a) shows a state where the pattern of the outer ceramic layer 41 is formed on the carrier member 40 using a ceramic green sheet. On the outer ceramic layer 41, an opening 41a having the same size as a surface electrode formed later is formed. As a method for forming the opening, a known method can be used, for example, forming a hole with a mechanical punch or using a screen printing method.

[0111] One example of a method of forming the outer ceramic layer 41 is as follows.

[0112] (1) For ceramic materials, use a material (BAS material) composed of components centered on Ba, Al, and Si, blend ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com