Functional pellet feed for high yield cows in lactation period

A technology of pellet feed and lactation period, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of limiting the production capacity of dairy cows, insufficient dry matter intake, long production cycle of dairy cows, etc., and improve the internal environment of dairy cow rumen microorganisms. , The effect of improving the production performance of dairy cows and increasing the rate of reproduction and conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

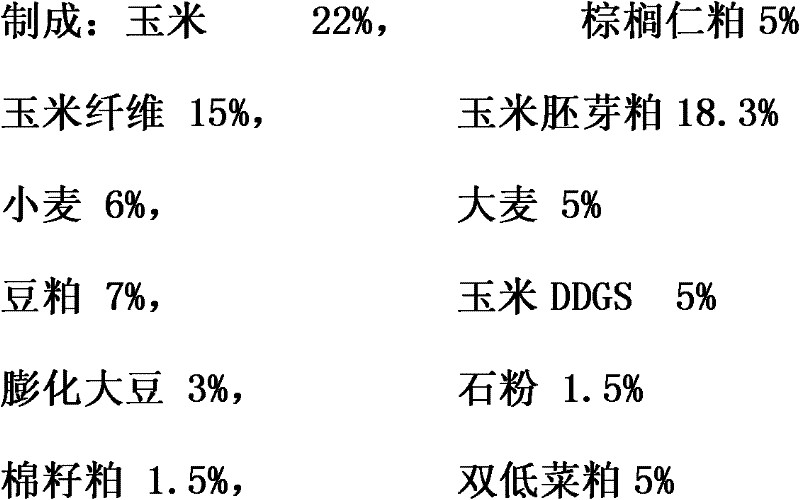

[0026] (1) A functional granular feed for high-yielding dairy cows during the lactation period, which consists of the following raw materials by weight percentage

[0027]

[0028]

[0029] Wherein the liquid molasses is a mixture of beet molasses or sugarcane molasses and water in a ratio of 60:40;

[0030] Among them, the dairy cow compound premix is produced by Liaoning Hefeng Animal Husbandry Co., Ltd. The approval number of this product is Liaoshiyuzi (2007) 003058, and the production license number is Shiyu (2010) 0803.

[0031] (2) Preparation method: After the above-mentioned raw materials are taken according to the proportion, they are pulverized to a particle size of less than 1mm, fully mixed and compressed into granules by a granulator.

Embodiment 2

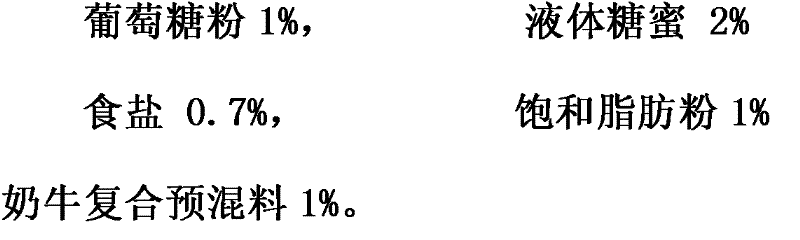

[0033] (1) A functional granular feed for high-yielding dairy cows during the lactation period, which is made of the following raw materials by weight percentage:

[0034]

[0035]Wherein the liquid molasses is a mixture of beet molasses or sugarcane molasses and water in a ratio of 60:40;

[0036] Among them, the dairy cow compound premix is produced by Liaoning Hefeng Animal Husbandry Co., Ltd. The approval number of this product is Liaoshiyuzi (2007) 003058, and the production license number is Shiyu (2010) 0803.

[0037] (2) Preparation method: After the above-mentioned raw materials are taken according to the proportion, they are pulverized to a particle size of less than 1mm, fully mixed and compressed into granules by a granulator.

Embodiment 3

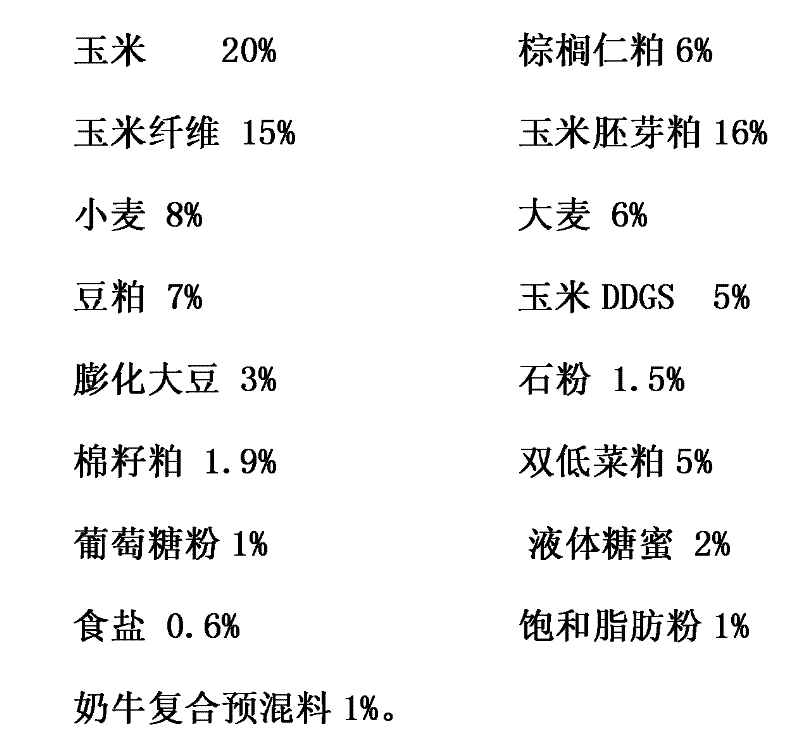

[0039] (1) A functional granular feed for high-yielding dairy cows during the lactation period, which is made of the following raw materials by weight percentage:

[0040]

[0041] Wherein the liquid molasses is a mixture of beet molasses or sugarcane molasses and water in a ratio of 60:40;

[0042] Among them, the dairy cow compound premix is produced by Liaoning Hefeng Animal Husbandry Co., Ltd. The approval number of this product is Liaoshiyuzi (2007) 003058, and the production license number is Shiyu (2010) 0803.

[0043] (2) Preparation method: After the above-mentioned raw materials are taken according to the proportion, they are pulverized to a particle size of less than 1mm, fully mixed and compressed into granules by a granulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com