Method for producing cogged wheel with herringbone gearing and method and device for generating control data

A technology of herringbone teeth and control data, applied in the related fields, can solve the problems of increased load in the boundary area, long processing time, less cutting volume, etc., and achieve the effect of reducing the load, increasing the strength of the teeth, and increasing the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

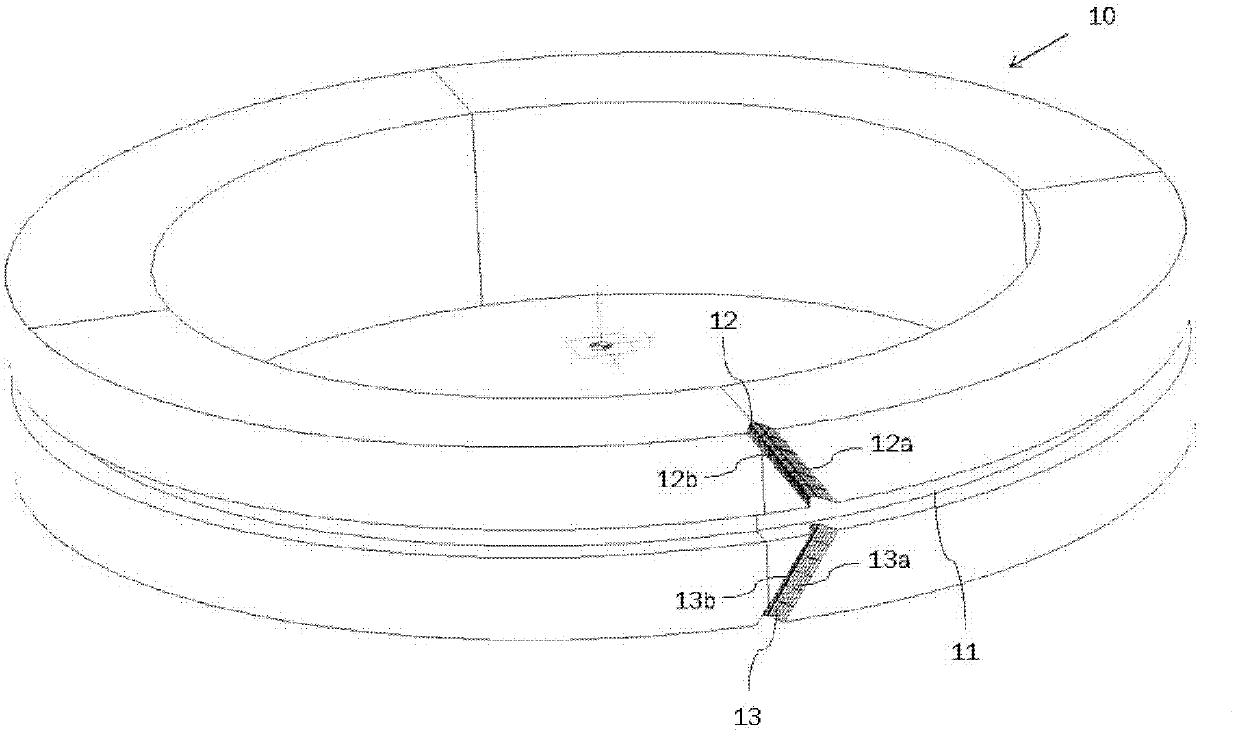

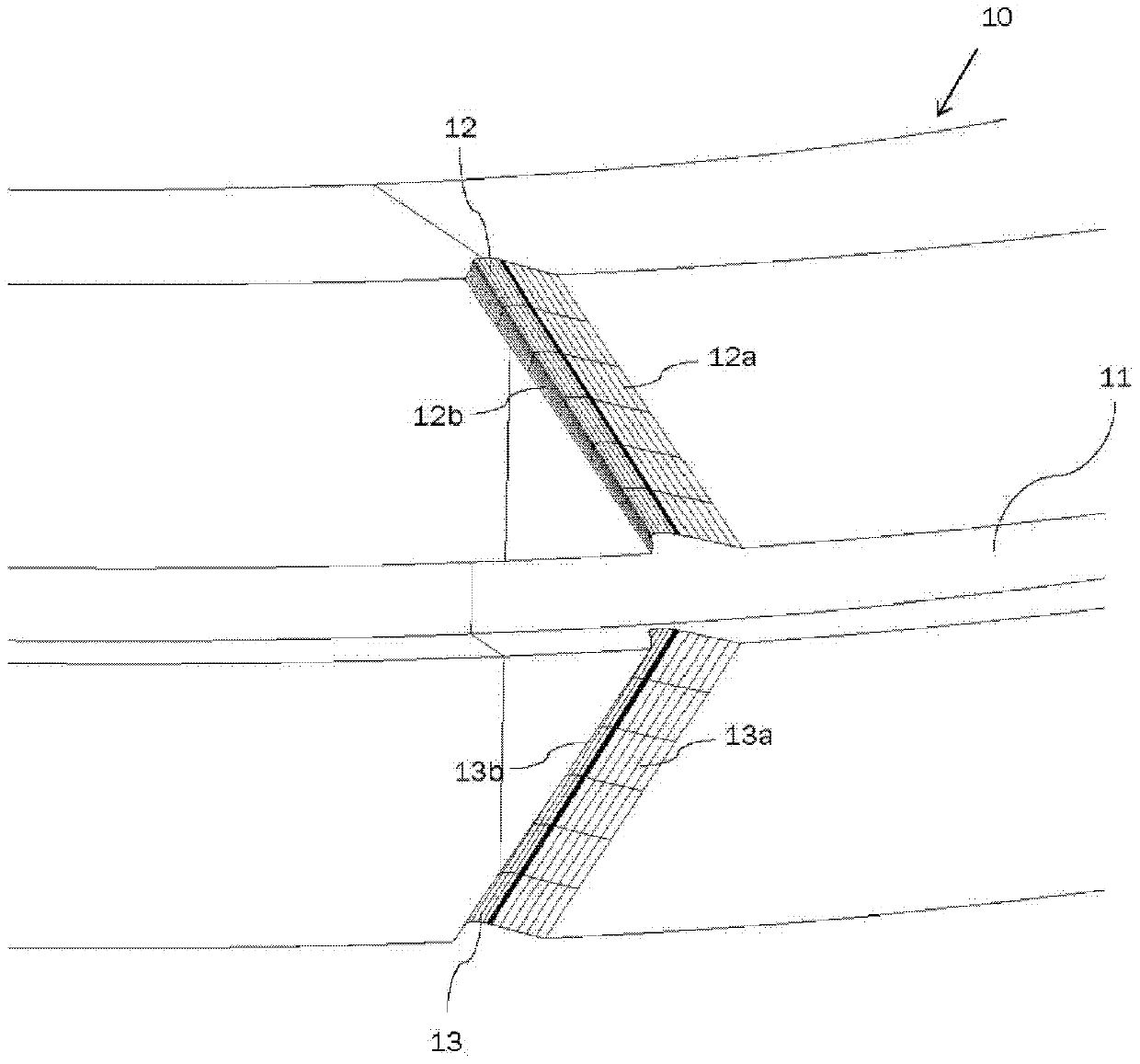

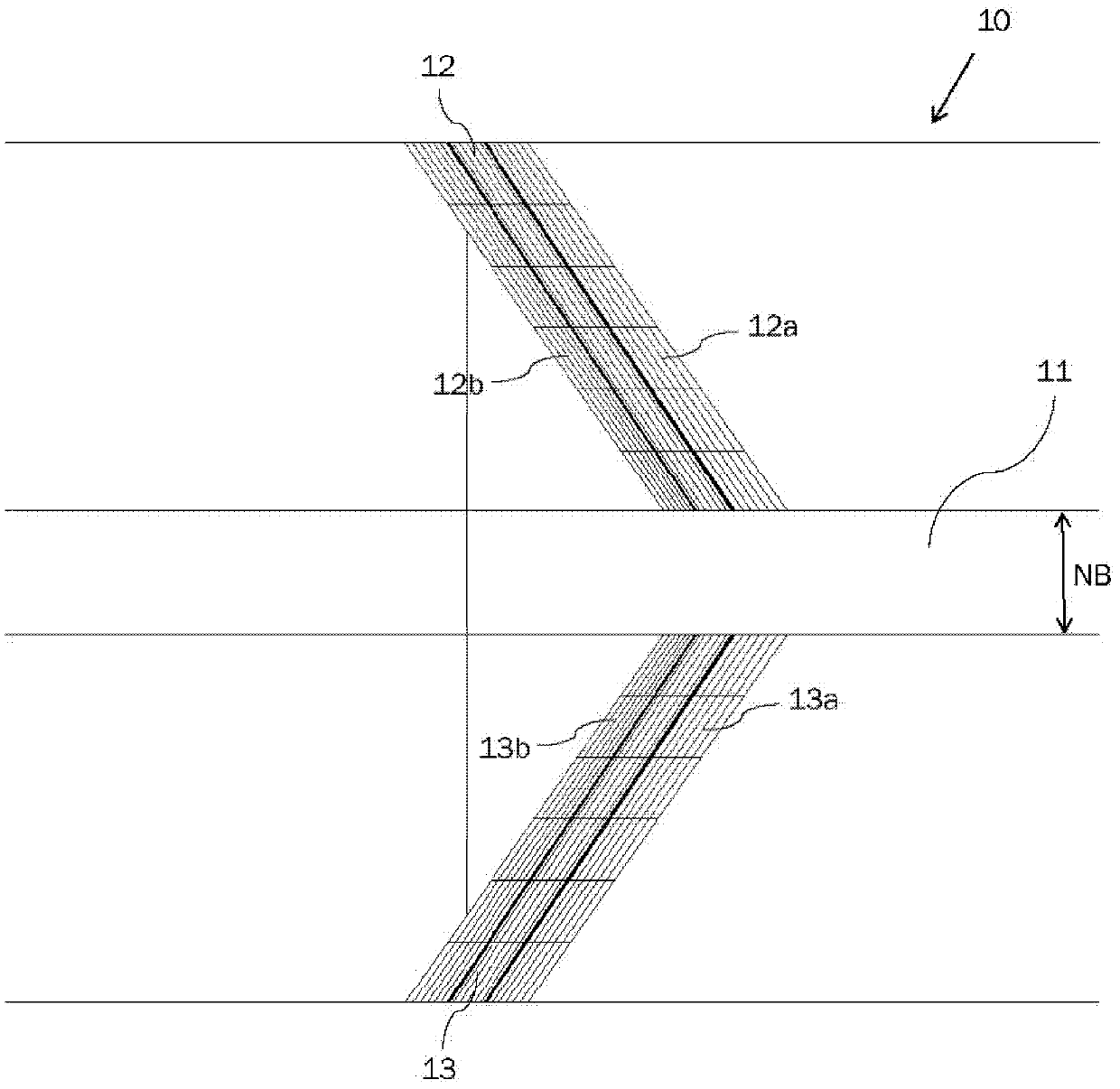

[0055] Preferred embodiments of the present invention are described below in conjunction with the accompanying drawings, however, the embodiments described here are only used to explain the present invention, not to limit the present invention. The invention is defined by the claims. Equivalent and / or similar features in the embodiments are indicated by the same reference numerals in the figures.

[0056] In the prior art, in order to separately calculate the geometric models of the workpiece with the gear, the gear and the tooth surface, for example, through a CAD system, the necessary gear information data should be predefined and / or determined. Therefore, in particular, the following data are necessary to calculate the mathematical or numerical model of the tooth flank:

[0057] Data representing the shape and dimensions of the entire workpiece before and / or after machining (e.g. data used to calculate unmachined part geometry and / or machined part geometry, respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com