Method for producing solid special conductive copper bar used for copper electrolysis

A production method, copper electrolysis technology, applied in the direction of metal rolling, etc., can solve the problems of loose and dense internal structure, coarse grains of cast structure, etc., achieve shortened hot rolling time, small metal loss, and low hot rolling cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1.) Semi-continuous casting:

[0056] High-purity cathode copper is selected as the raw material, and then melted in a core power frequency induction furnace, the copper liquid surface is covered with calcined charcoal, the furnace temperature is 1160oC, and the casting temperature is 1160oC. The surface of the mold is sealed and cast under the protection of gas. The casting speed is 4m / h, and the cooling water pressure is 1.5kg / cm. 2 . After casting, the copper slab is lifted out of the kang, and then sawed to a length of 123x232x 1560mm, which is the copper slab used in the embodiment.

[0057] 2.) Heating:

[0058] This example uses 123x 232x 1560mm (height x width x length) copper slab as raw material, and heats it to 850oC in a three-stage continuous heating furnace (existing furnace) for 1.5 hours, and the pressure in the furnace is slightly positive , And then hot-rolled.

[0059] 3.) Hot rolled billet:

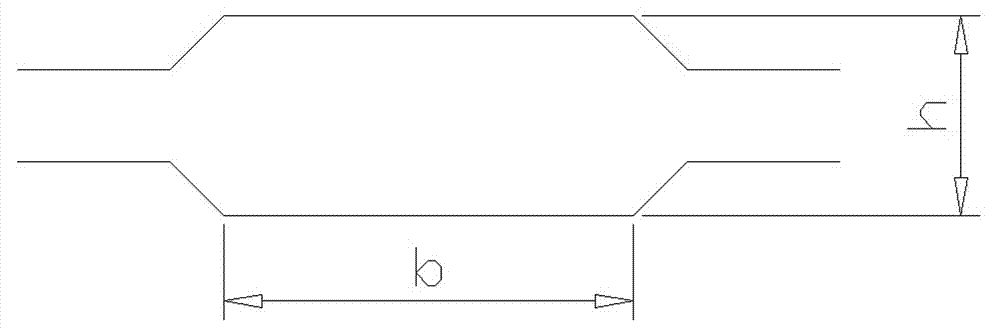

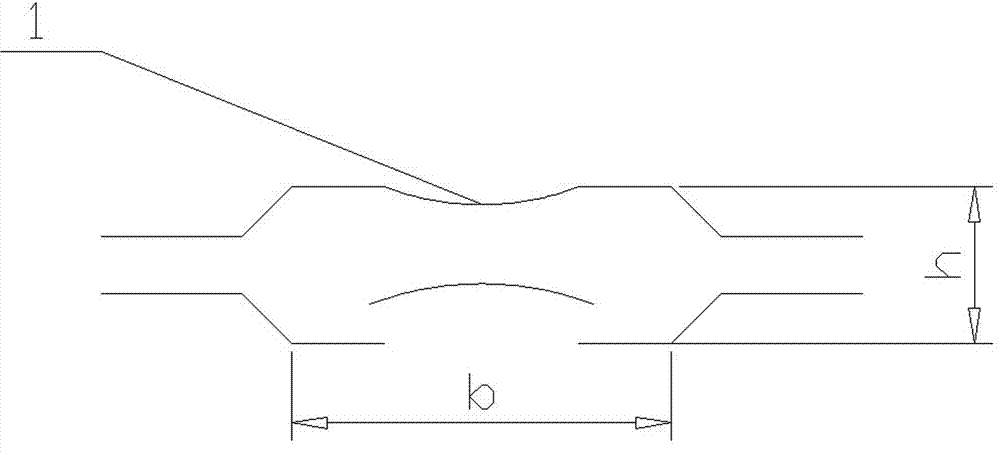

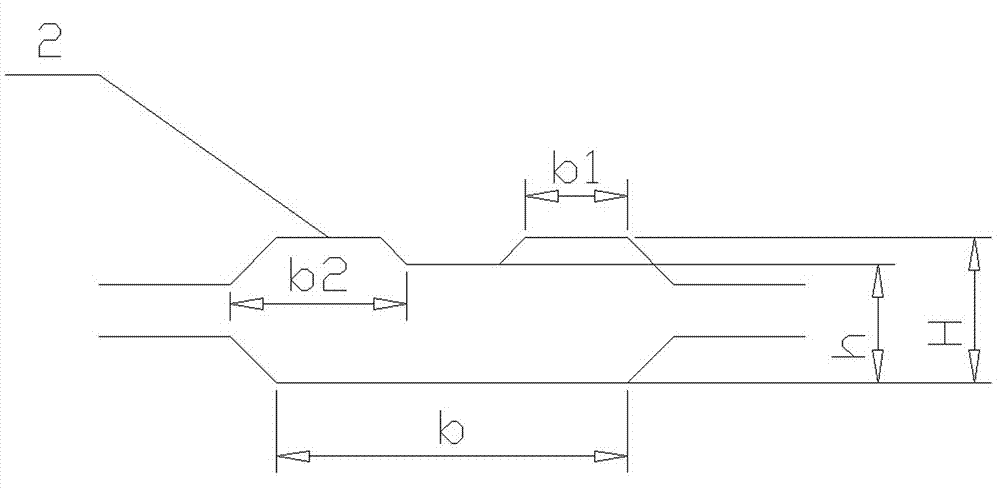

[0060] The heated copper slabs are hot-rolled in a set of pass ...

Embodiment 2

[0080] 1.) Semi-continuous casting:

[0081] High-purity cathode copper is selected as the raw material, and then melted in a core power frequency induction furnace. The copper liquid surface is covered with calcined charcoal. The furnace temperature is 1180oC and the casting temperature is 1180oC. The surface of the mold is sealed and casted under the protection of gas. The casting speed is 6m / h, and the cooling water pressure is 2.5kg / cm. 2 . After the casting is finished, the copper slab is lifted out of the kang, and then sawed to a length of 132x243x1560mm, which is the copper slab used in the embodiment.

[0082] 2.) Heating:

[0083] In this example, 132x 243x 1560mm (height x width x length) copper slabs are used as raw materials and are heated to 900oC in a three-stage continuous heating furnace (existing furnace) for 2 hours, and the pressure in the furnace is slightly positive , And then hot-rolled.

[0084] 3.) Hot rolled billet:

[0085] Groove 1, boss 2, copper sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com