Generation system for rail cars

A technology for power generation systems and railway vehicles, which can be used in railway vehicles, electric braking systems, control systems, etc., and can solve problems such as heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

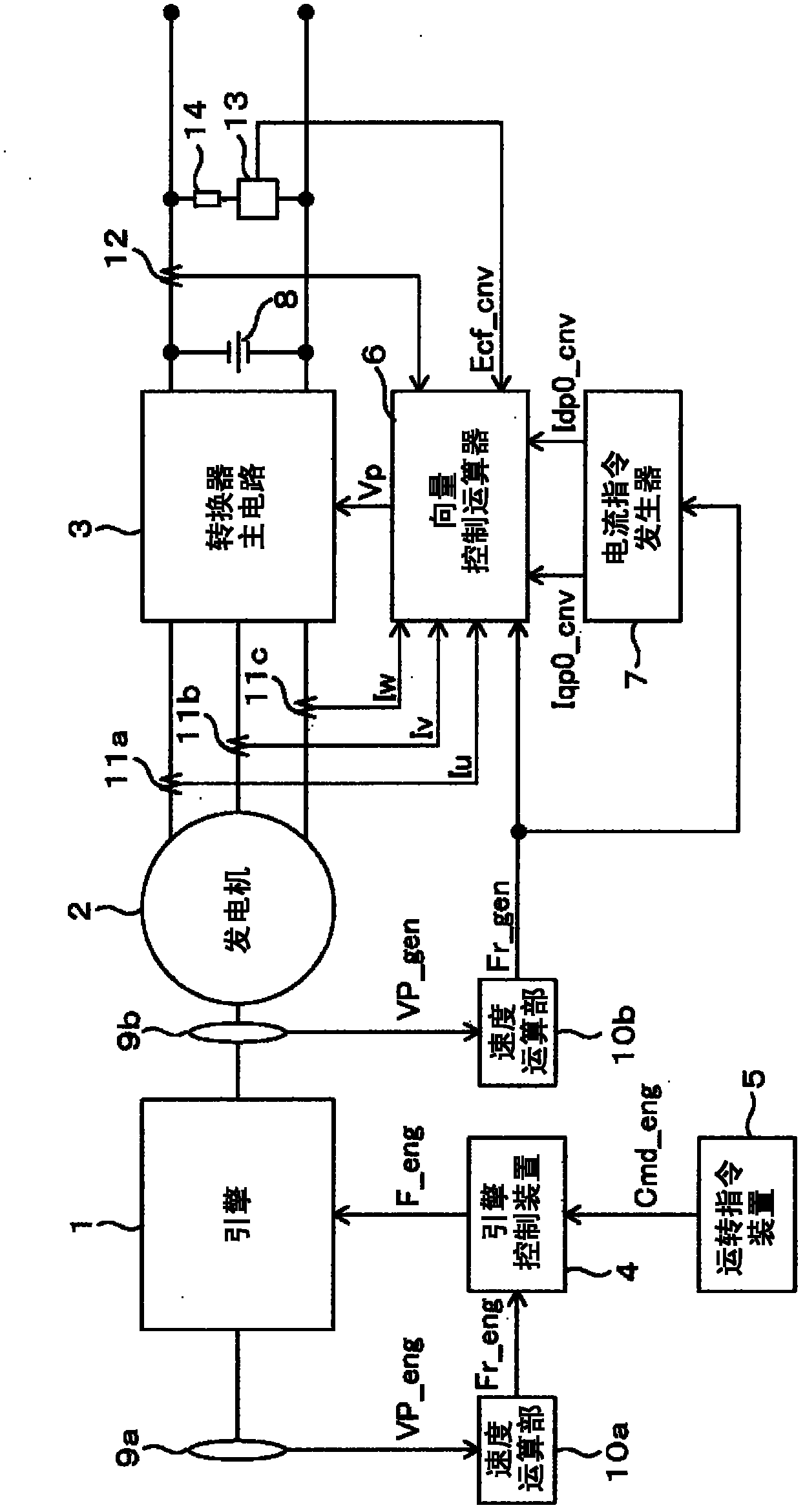

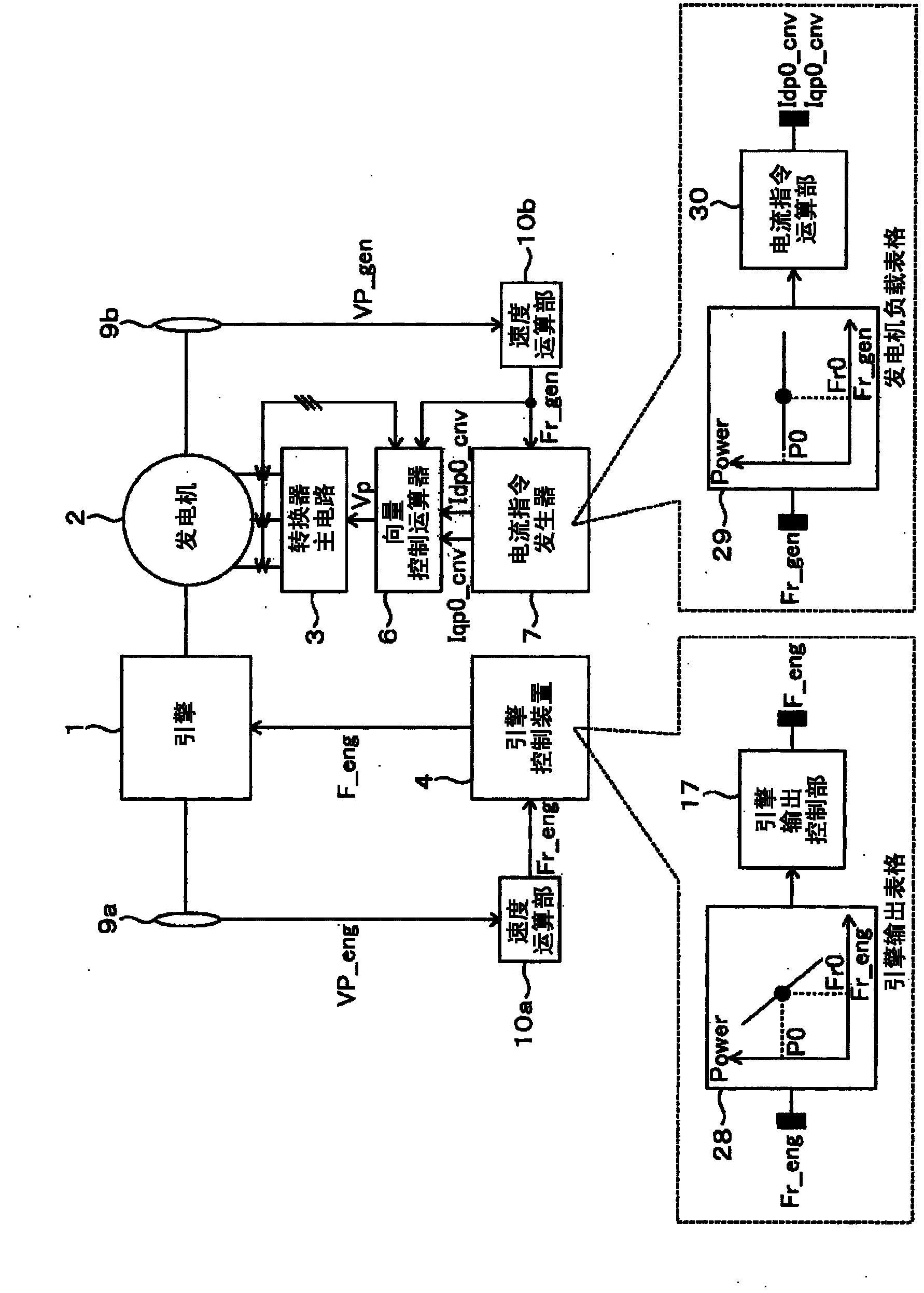

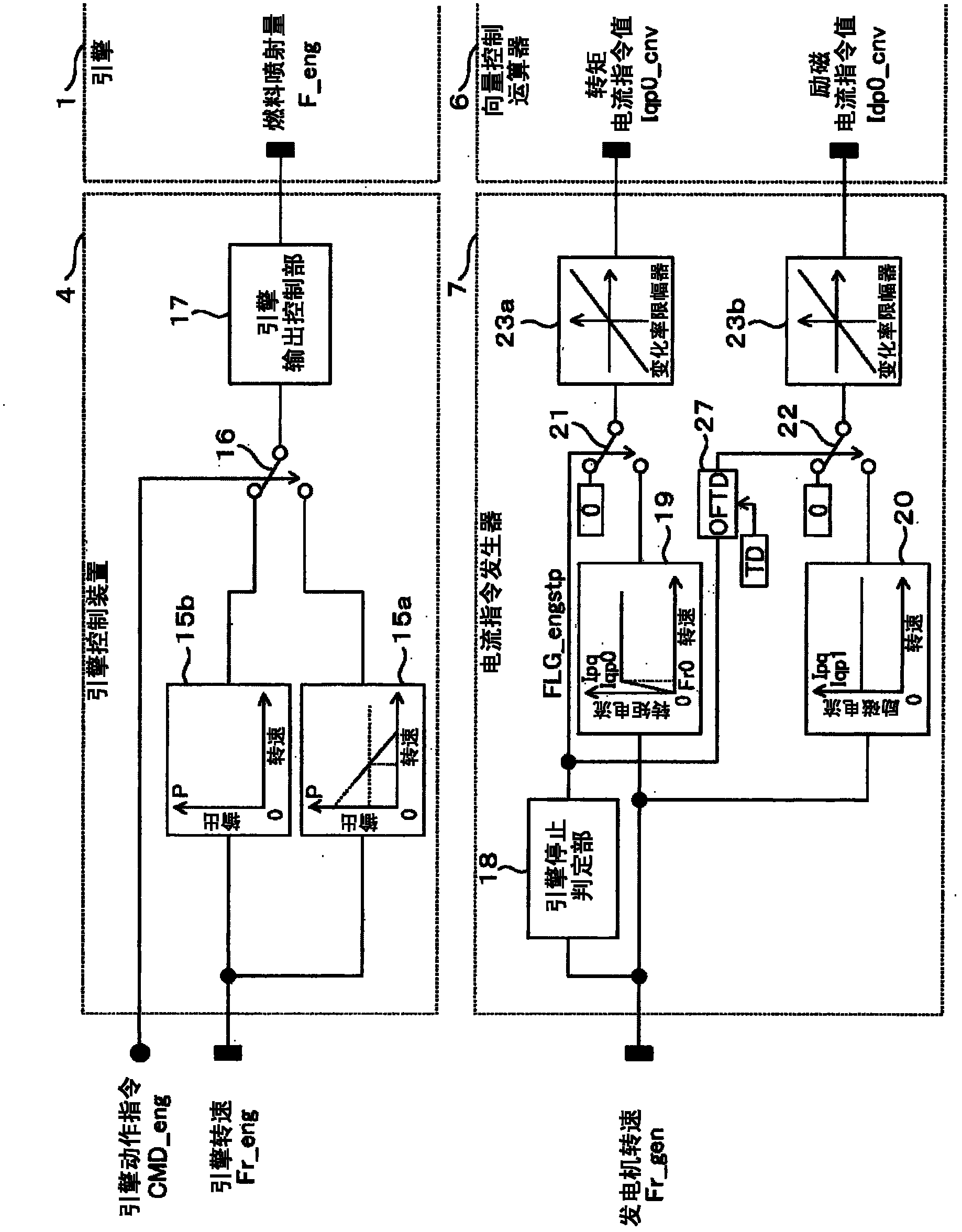

[0067] figure 1 It is a figure which shows the equipment structure of one Embodiment in the railway vehicle engine control system of this invention.

[0068] The engine 1 outputs shaft torque based on a fuel injection amount command F_eng from the engine control device 4 . The generator 2 is connected to the engine 1 via a drive shaft, and takes the shaft torque of the engine 1 as input, converts it into three-phase alternating current, and outputs it.

[0069] The converter main circuit 3 receives the three-phase AC power output from the generator 2 as input, converts it into DC power, and outputs it. The DC side voltage of the converter main circuit 3 is adjusted to a voltage value within a certain range by a DC voltage source such as a power storage device or a power generation system (not shown).

[0070] The vector control calculator 6 uses the three-phase AC currents Iu, Iv, and Iw detected by the AC current detectors 11a, 11b, and 11c, the rotational speed signal Fr_...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com