Uniform vulcanization method of seismic isolation rubber support of building

A vibration-isolating rubber and rubber bearing technology, which is applied in building structures, buildings, building components, etc., can solve the problems of non-reusable production materials, low production efficiency, waste of raw materials, etc., to shorten vulcanization time and high production efficiency. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

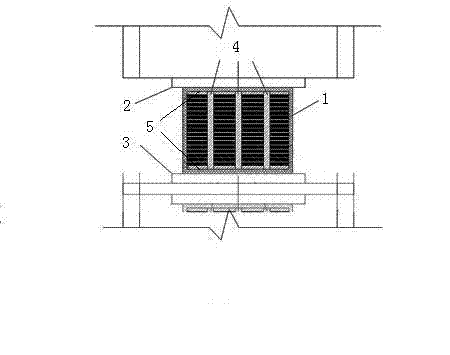

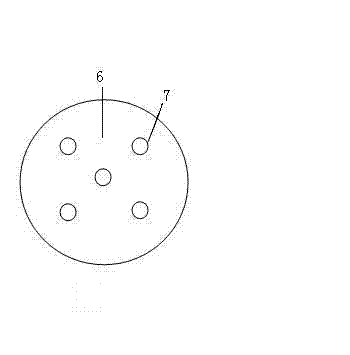

[0021] Example 1. Use the method of the present invention to vulcanize under the condition of 120 ℃ * 14h * 20Mpa to the laminated rubber bearing of height 400mm, diameter 1000mm, 30 layers. The distribution form of the steel circular section heat conduction rod of embodiment 1 is shown in figure 1 , figure 1 Middle 6 is a rubber bearing cover plate, and 7 is a metal heat conducting rod. There are 5 cylindrical copper metal heat conducting rods 7 with a diameter of 38 mm evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com