Soft coal seam long-wall high-mining-height comprehensive mechanized coal mining end mining method

A comprehensive mechanization and large mining height technology, applied in ground mining, earth drilling, underground mining, etc., can solve problems such as coal wall collapse, and achieve the effect of simple support, high strength and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

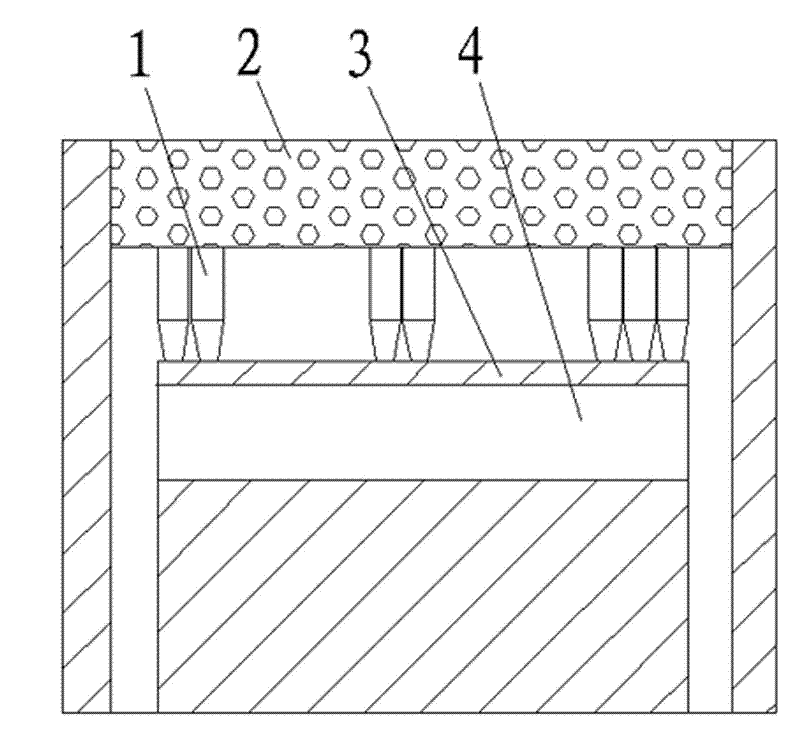

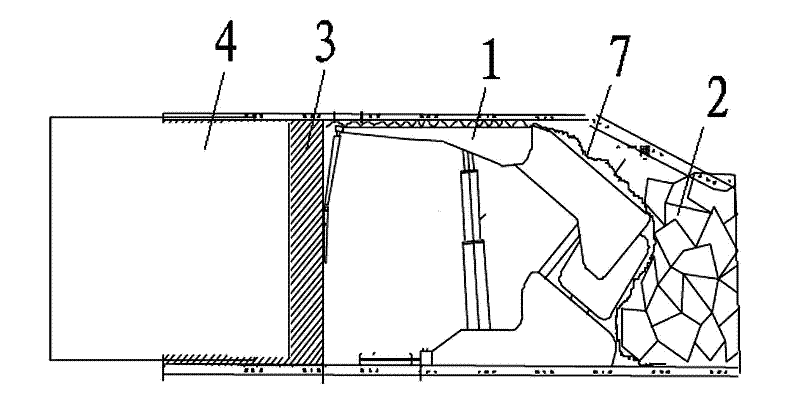

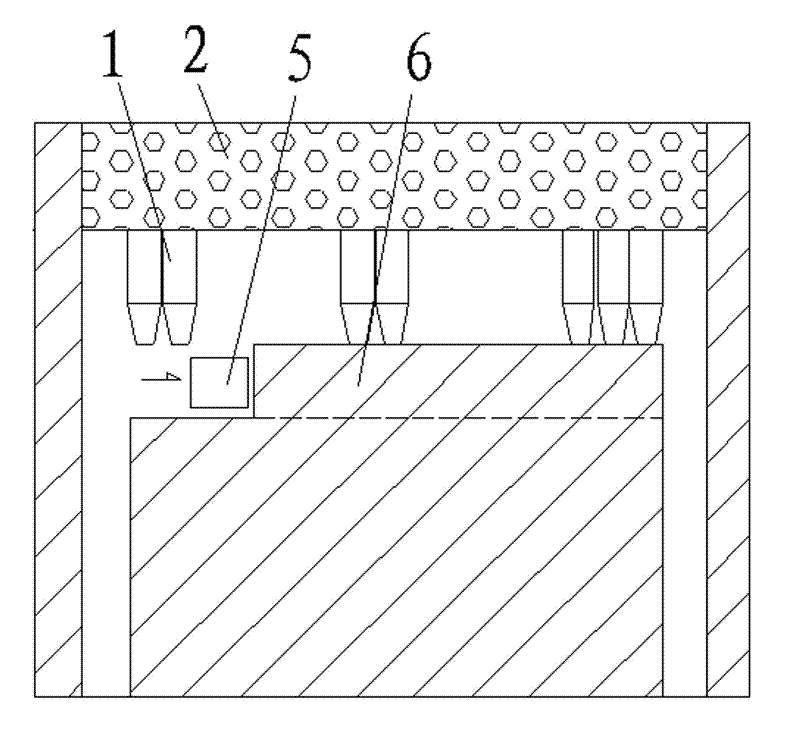

[0016] Such as image 3 , 4 As shown, in the soft coal seam longwall with a hardness coefficient of less than 1.5 and a large mining height of more than 3.5 meters, the method of comprehensive mechanized coal mining at the end of mining is as follows:

[0017] 1. The layout of the comprehensive mechanized large mining height coal mining face adopts longwall mining over 100 meters, at least adopts the layout method of one entry and one return, and manages the roof with the method of all crossing and falling.

[0018] 2. The final mining stage from the start of the final mining to the support 1 stop moving forward is consistent with the normal final mining process, that is, the first pass of the net on the top of the support 1 starts at a distance (20m) from the mining face to the stop production line, and The third trip begins to go up the double net and starts to go up the steel wire rope, after the metal net 7 compaction behind the tail beam of the last support, reaches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com