Bionic engine, and implementation method thereof

A realization method and engine technology, applied in machine/engine, non-variable engine, mechanical equipment, etc., can solve the problems of incomplete scavenging, small relative sliding amount, loss of control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

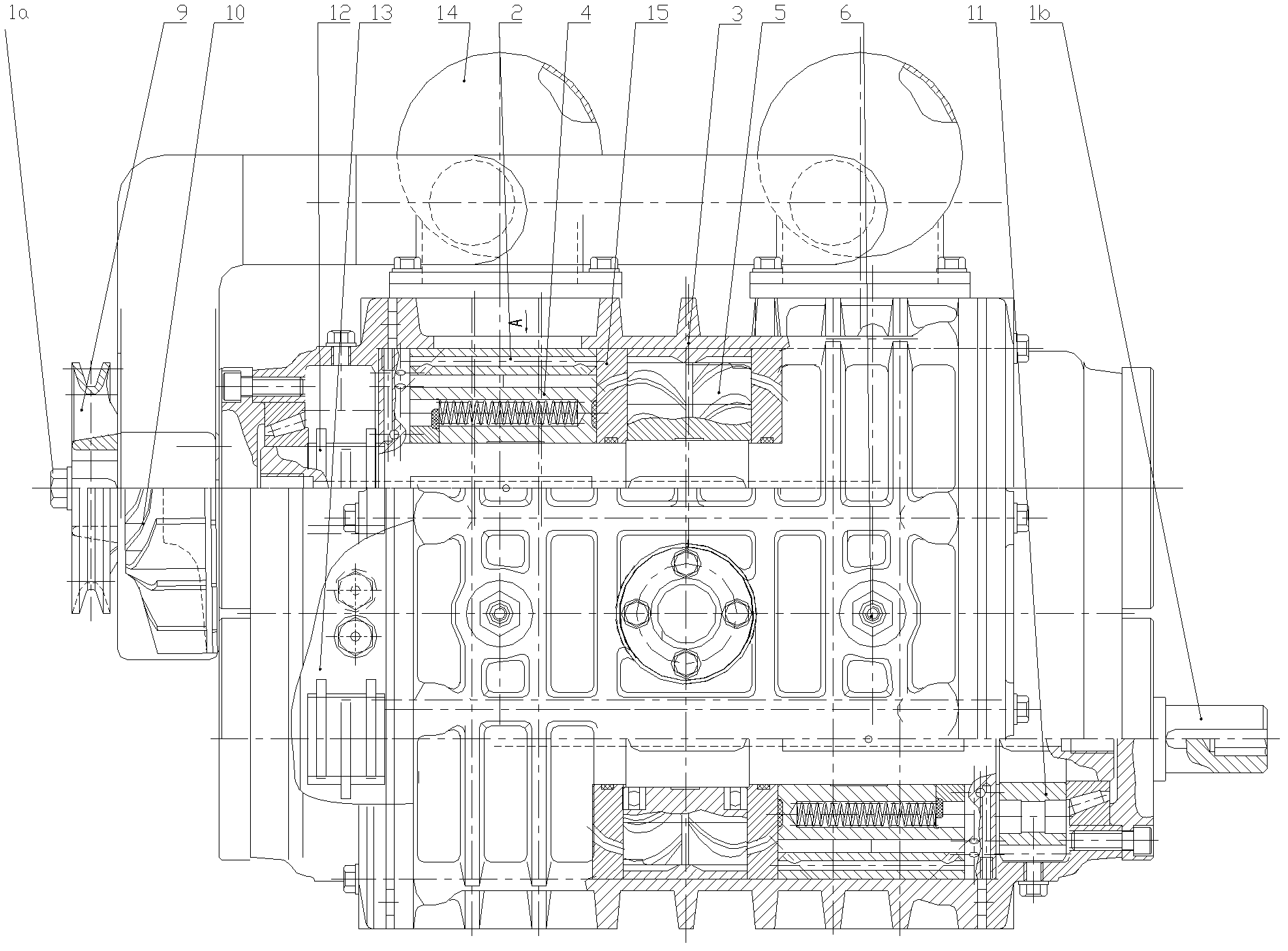

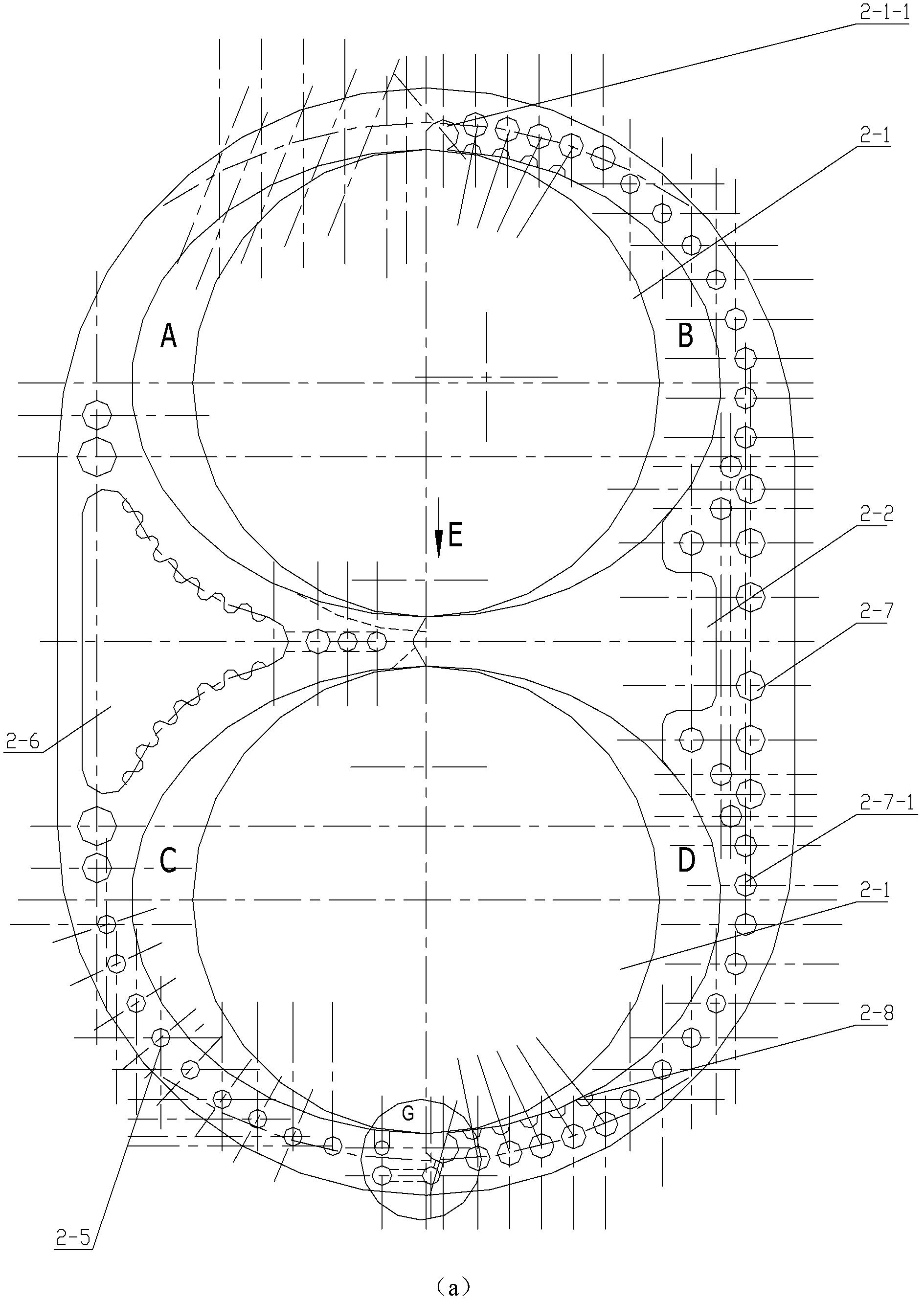

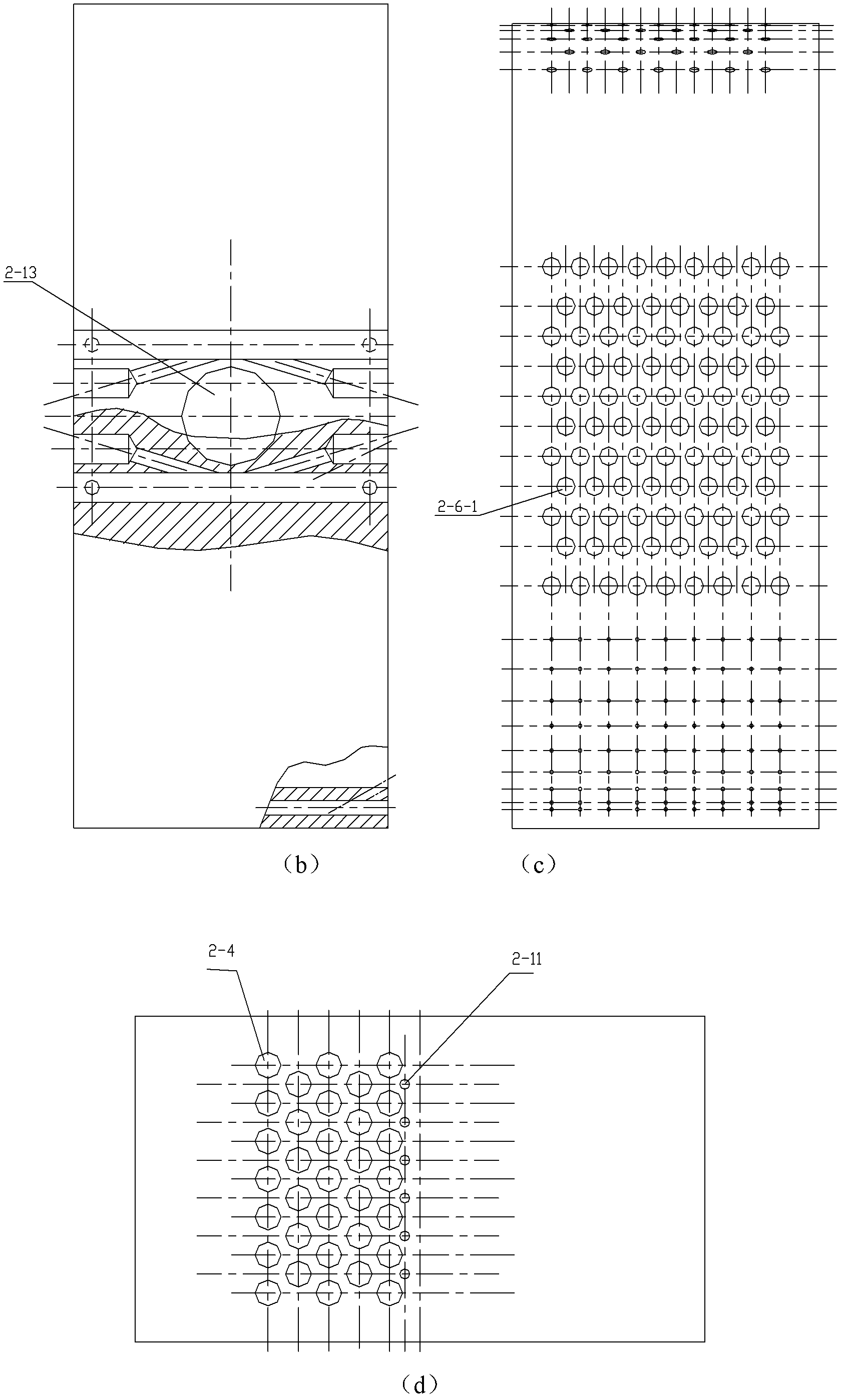

[0068] see Figure 1-7 , a bionic engine, the whole machine includes two sets of double The rotor stator pair and the turbine pair in the middle; the main shaft includes the input shaft and the output shaft, and the main shaft runs through the rotor stator pair and the turbine pair in parallel; the compressor wheel, the cam for driving the oil pump, and the front and rear parts are installed on the input shaft. Rotor, turbine and synchronous gear, a set of corresponding front and rear parts are installed on the output shaft Energy rotor, turbine and synchronous gear, the output shaft extends out to the output end, and the output shaft and input shaft work synchronously through the synchronous gear;

[0069] The body of the bionic engine is provided with a pressure accumulator;

[0070] pair Energy rotor stator pair includes energy stator and rotor;

[0071] each double In the rotor-stator pair, The stator is equipped with two symmetrical cavities up and down, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com