Concrete diameter construction survey control method for cooling tower and large-scale construction barrel

A control method and construction measurement technology, applied in the field of construction engineering, can solve the problems of hidden safety hazards of on-site measurement personnel, difficult to control measurement accuracy, inconvenient operation, etc., and achieve the effects of fast measurement, improved measurement efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

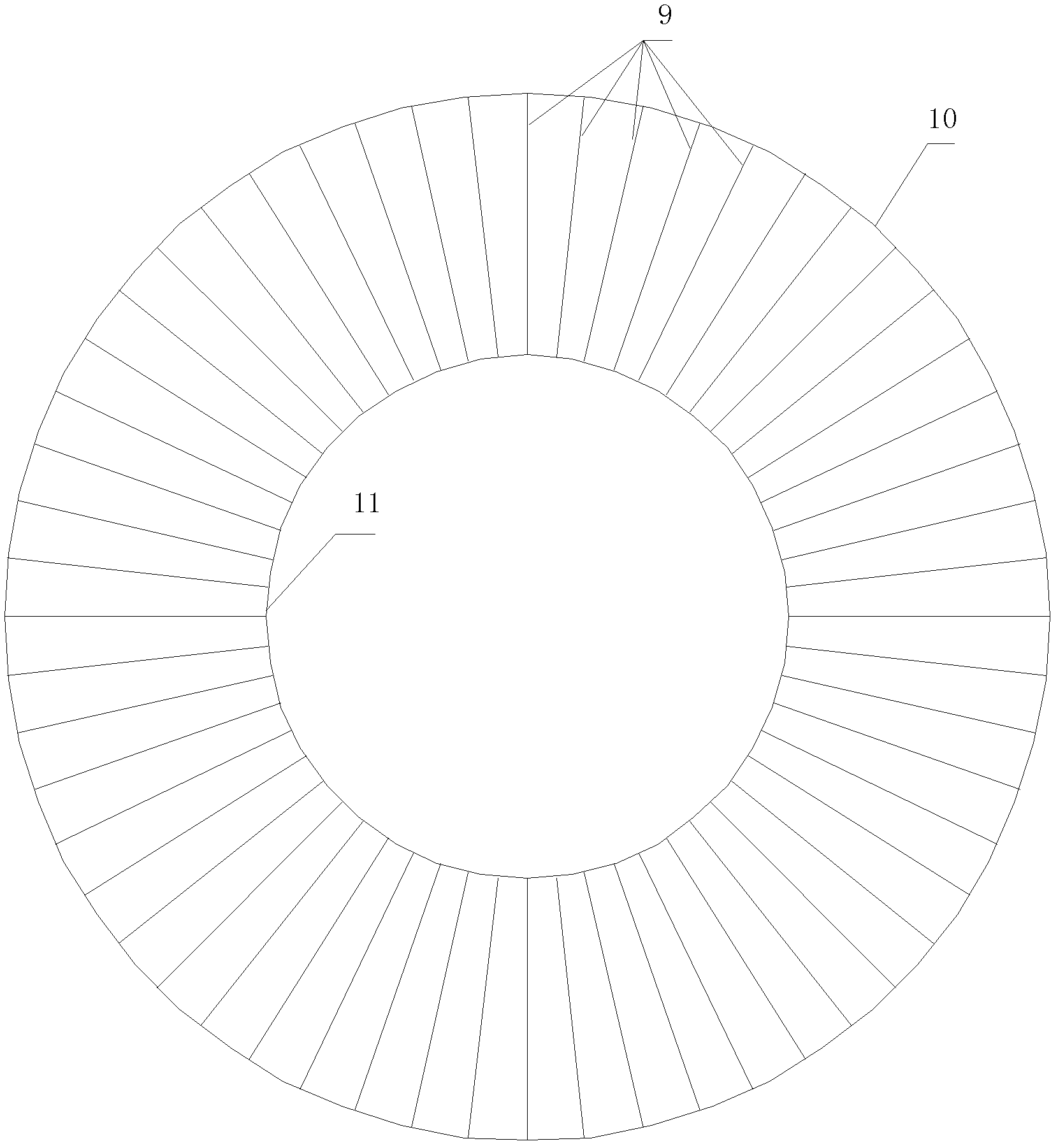

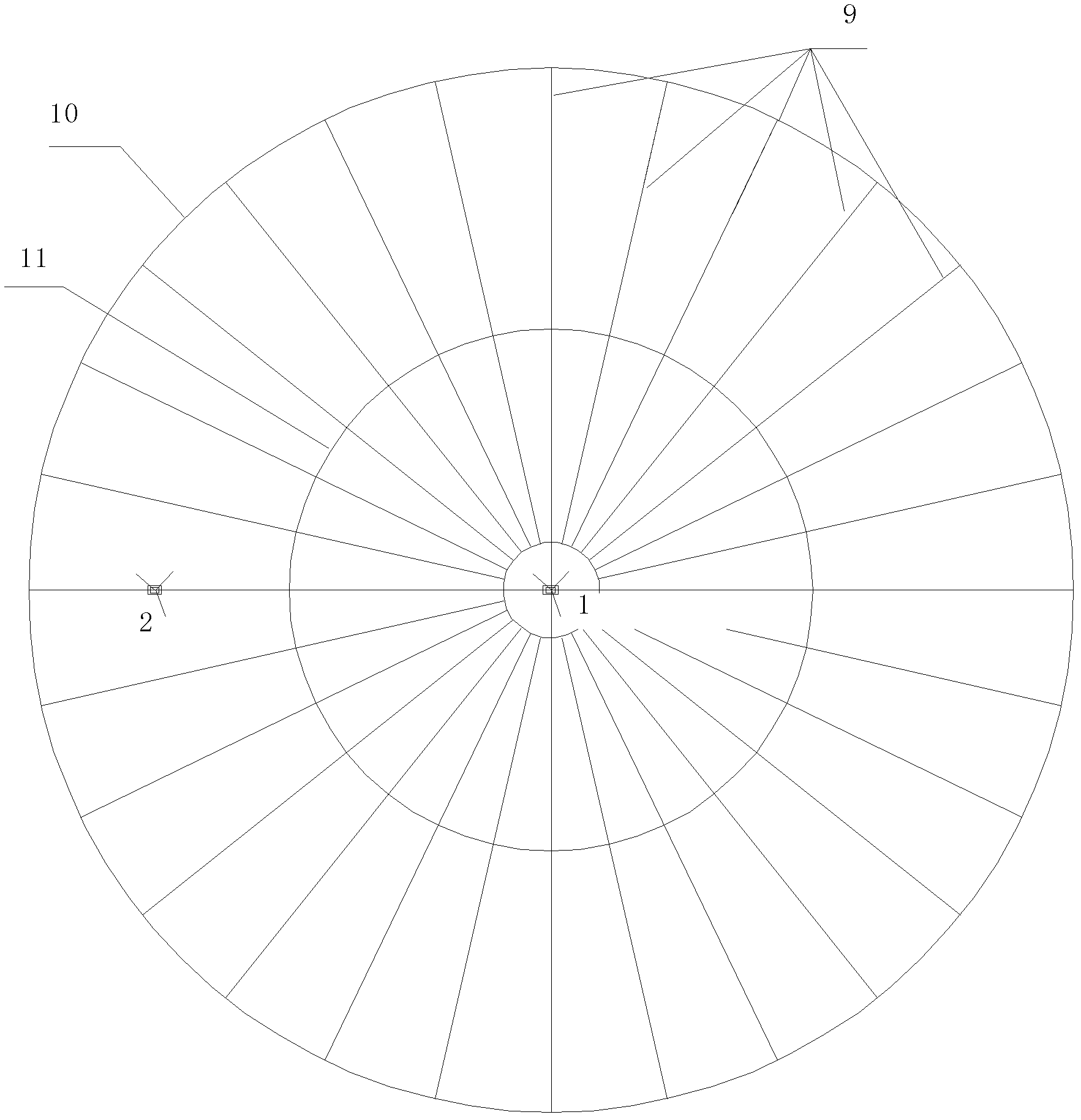

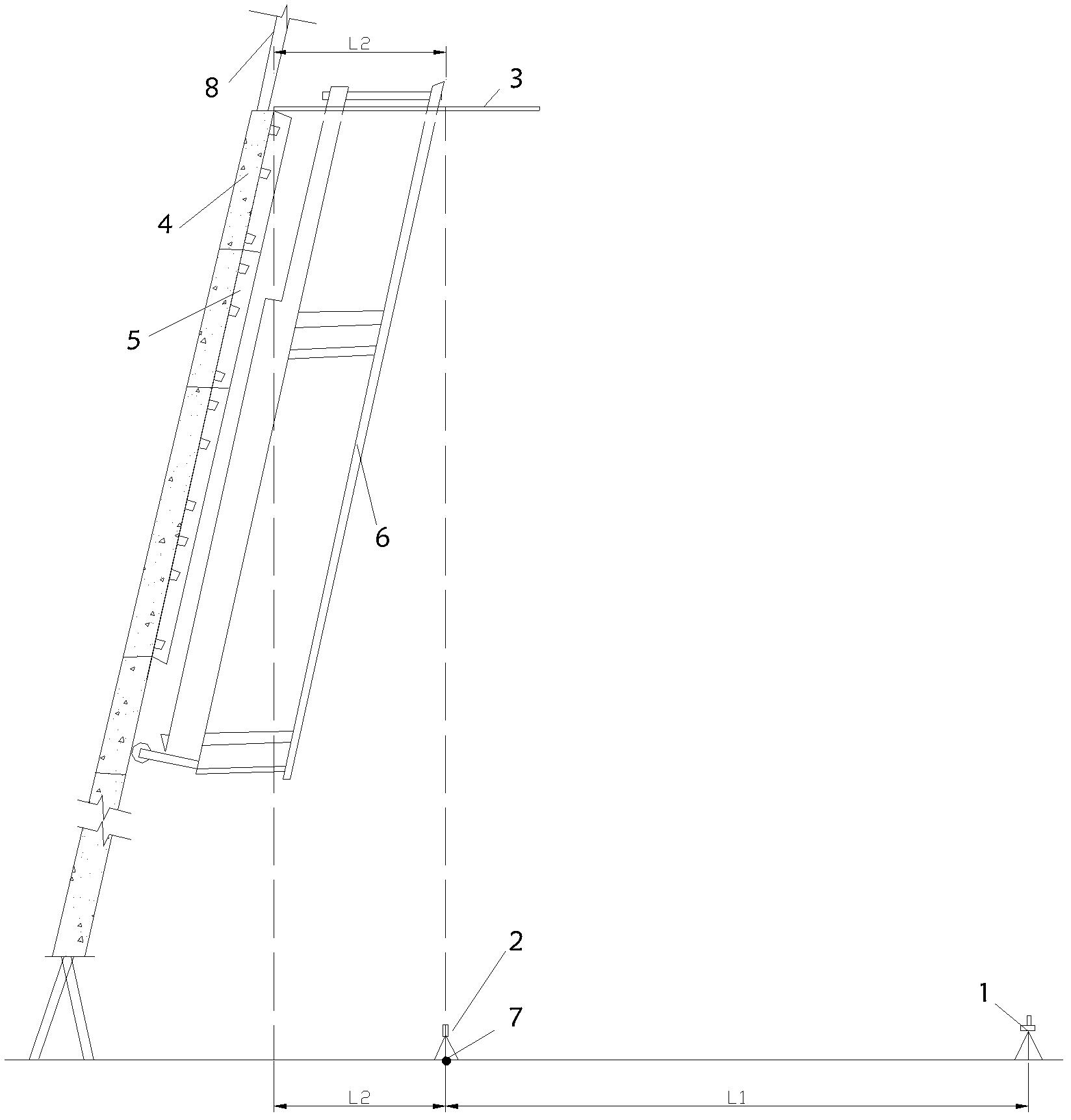

[0017] refer to figure 1 , determine the number of climbing formwork guide rails based on the maximum circumference at the bottom of the cooling tower duct, the minimum circumference at the throat and the size of the climbing formwork platform to ensure that the climbing formwork platform can be connected at the bottom of the duct and can pass through the throat of the duct smoothly. Divide the circumference of the bottom by the length of the platform board stretched to the limit position to get an integer N1, divide the circumference of the throat by the length of the platform board contracted to the limit position to get another integer N2, select the largest number from N1 and N2 as the climbing The number of mold guide rails is N; divide the base plate into N equal parts with the center of the circular base plate as the center, mark the base plate with ink lines an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com