Neutron nondestructive detection system

A non-destructive testing, neutron technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of limited thick sample detection, etc., to achieve the effect of convenient practical application and flexible and adjustable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

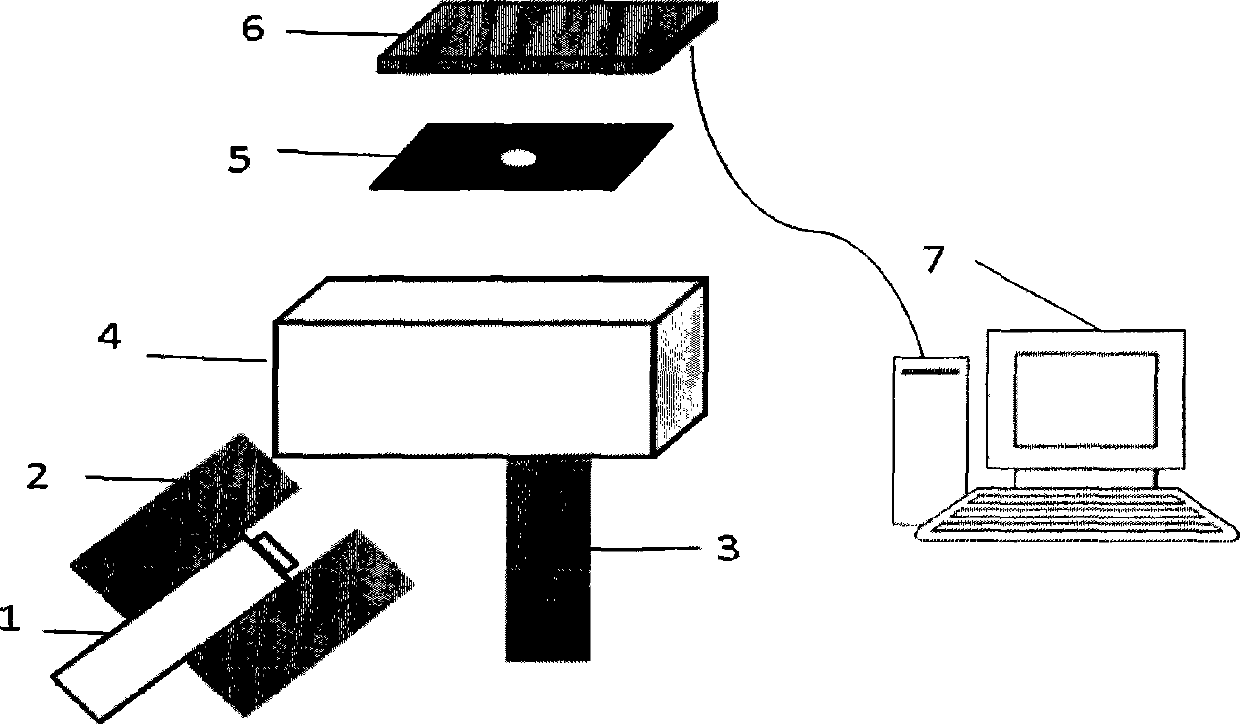

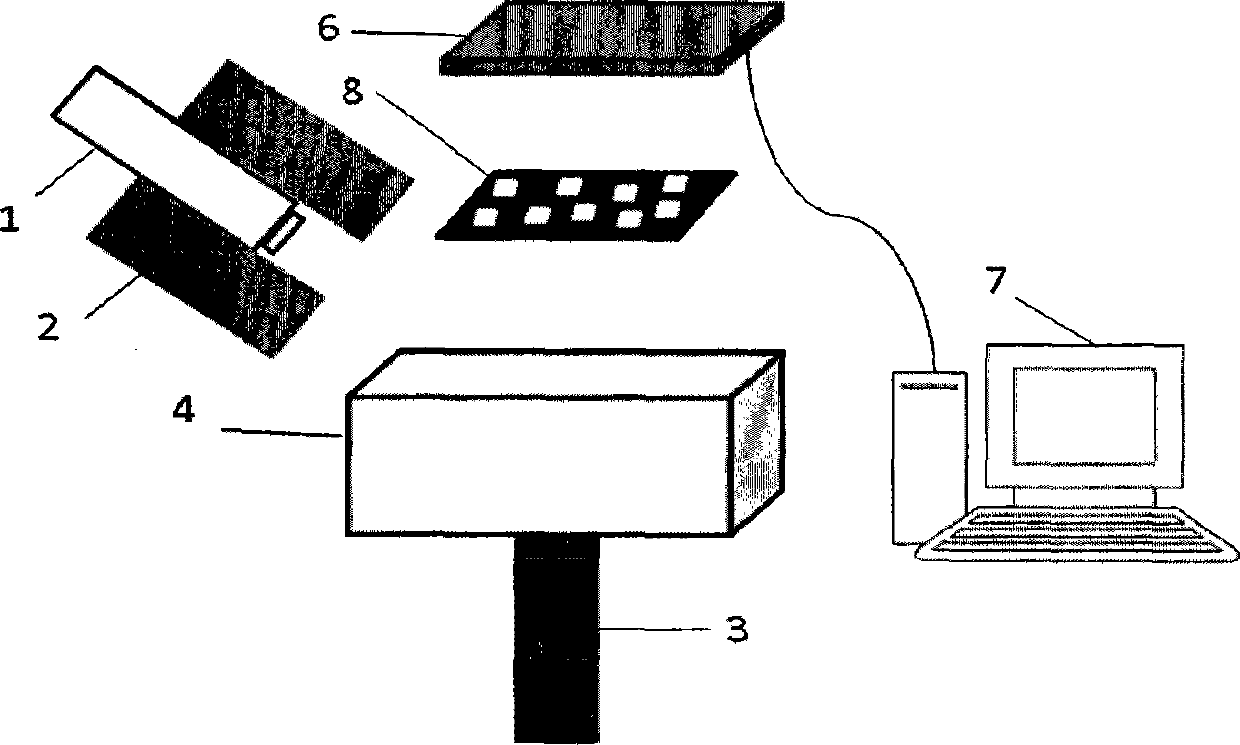

[0018] The biggest difference between neutron self-thermal imaging and existing neutron detection methods is that it can flexibly lay out the position of the neutron source and imaging system. figure 1 with figure 2 The specific implementation is described.

[0019] figure 1 It is a layout diagram of self-thermal imaging using small hole imaging. First, the test sample is placed on the test sample placement device, and the neutron source device and the imaging device are respectively placed on both sides of the sample. The fast neutrons produced by the neutron source are directly incident into the test sample, slowing down the diffusion in the sample, and finally forming a stable thermal neutron distribution in the sample. Where there is a defect, because the material at the defect has a different cross-section for neutrons, the thermal neutron distribution at this point is significantly different from the surrounding thermal neutron distribution. The small hole imaging method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com