Filtering equipment for electrolyte and filtering method thereof

A technology of filtration equipment and filtration method, applied in the field of filtration, can solve problems such as difficult removal, and achieve the effects of reducing labor intensity, simple control, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

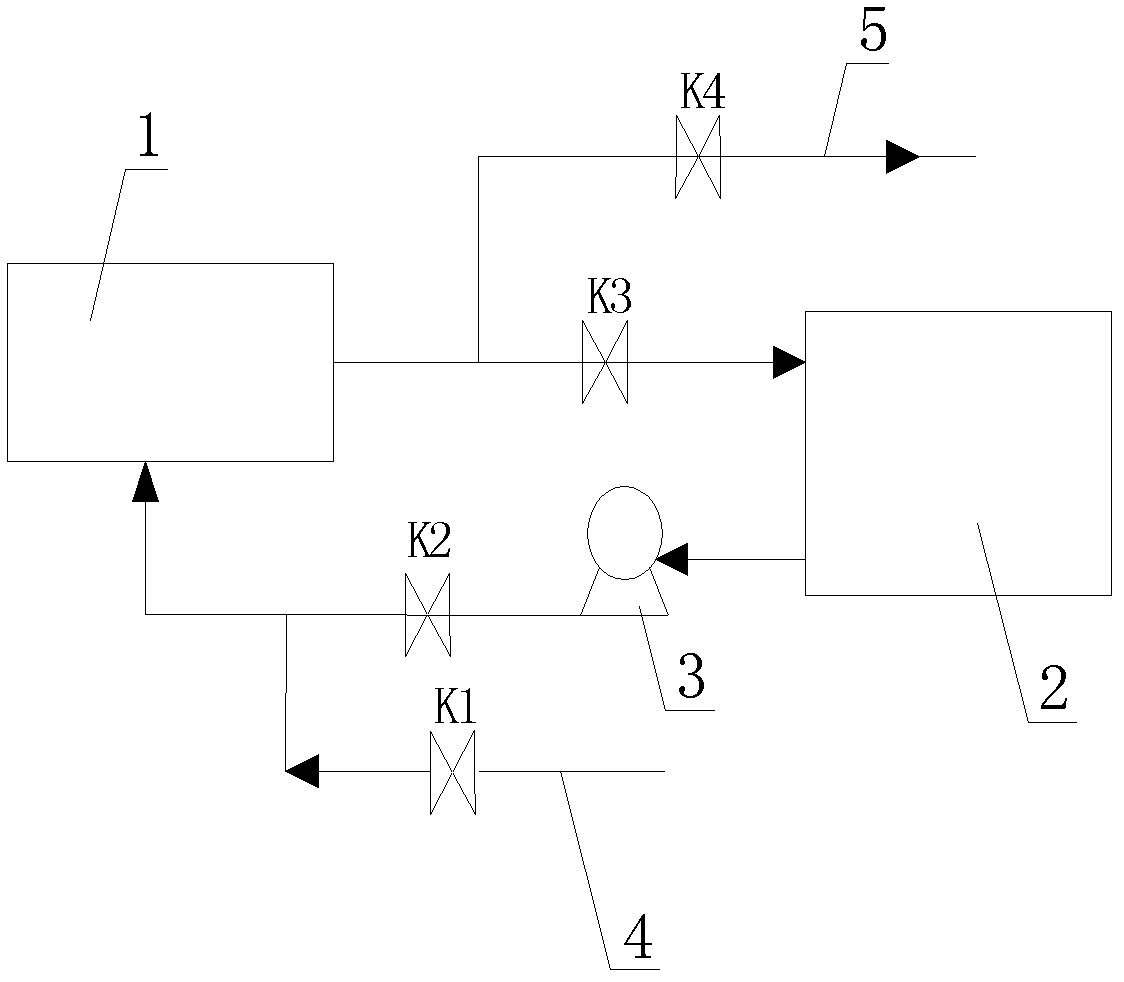

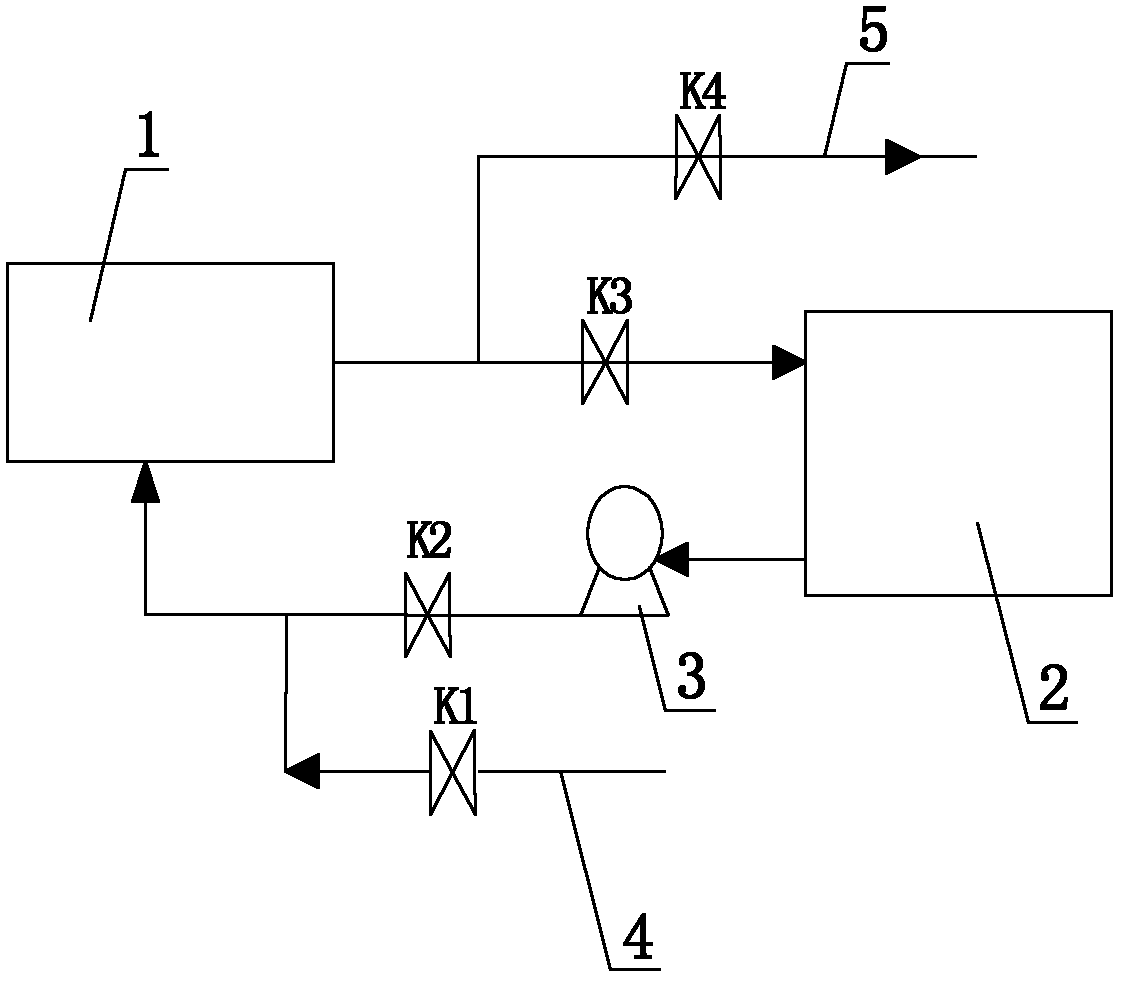

[0026] see figure 1 , a filter equipment for electrolyte, filter 1, filtrate inlet pipe 4 and filtrate outlet pipe 5, a circulation pipeline is connected between the filtrate inlet pipe 4 and filtrate outlet pipe 5 of filter 1, and in the circulation pipeline The diatomite solution storage tank 2 and the circulation pump 3 are connected in the middle, the circulation pump 3 is connected between the diatomite solution storage tank 2 and the filtrate inlet pipe 4, and the circulation pipe between the circulation pump 3 and the filtrate inlet pipe 4 is connected. There is a material discharge control valve K2, and a return material control valve K3 is connected to the circulation pipeline between the diatomite solution storage tank 2 and the filtrate outlet pipe 5. Among them, filter 1 selects a filter bag filter with a pore size of 20 microns.

[0027] Using the filtration method of the filtration equipment, check the filter circulation system before coating. The filtrate inlet...

Embodiment 2

[0029] The equipment used in this example is the same as that of Example 1, the only difference is that filter 1 is a filter element with a pore size of 20 microns; using the filtration method of this filter equipment, check the filter circulation system before coating, and the filtrate inlet pipe 4 The circulation with the filtrate outlet pipe 5 is normal, and it is in a positive pressure state. Close the discharge control valve K2 and the return control valve K3. During filtration, first add 200Kg 100 mesh diatomite and 2000L water to the diatomite solution storage tank 2, After mixing, the mixed solution A is obtained, and the return control valve K3 is opened to put the mixed solution A into the diatomite solution storage tank 2 to 1 / 2, the discharge control valve K2 is opened, and the circulating pump 3 is started at the same time to make the mixed solution A. Circulating flow with filter 1 in diatomite solution storage tank 2 at a speed of 2.2Kg / min, coating filter 1 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com