Stripping device

A wire frame and wire guide technology, applied in the field of chemical fiber production, can solve the problems affecting the product grade of filament products, the difficulty of keeping the same amount of wire stripping, and the high labor intensity, achieving simple structure, high work efficiency, and labor intensity. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The stripping device of the present invention will be further described in detail through specific embodiments below.

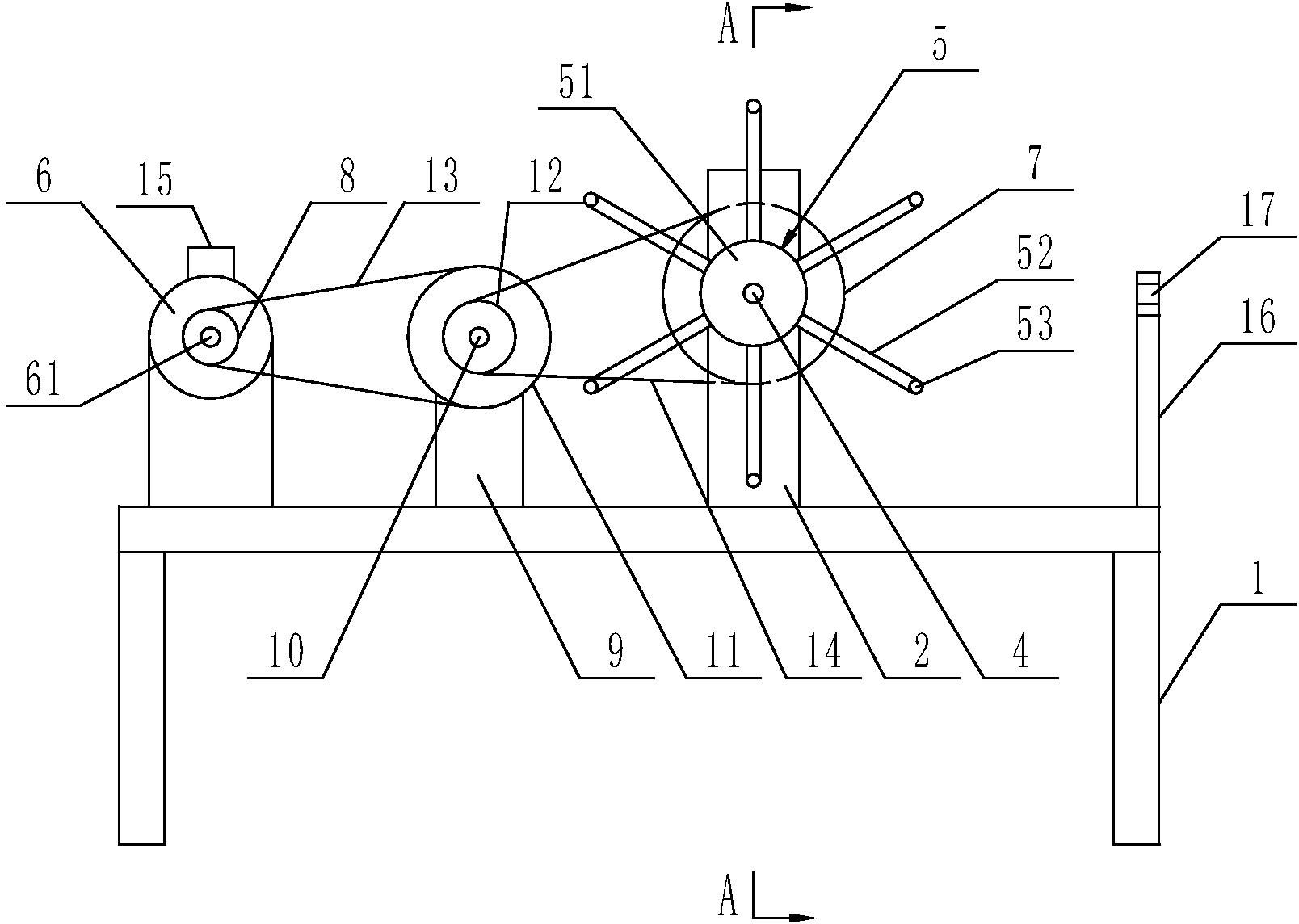

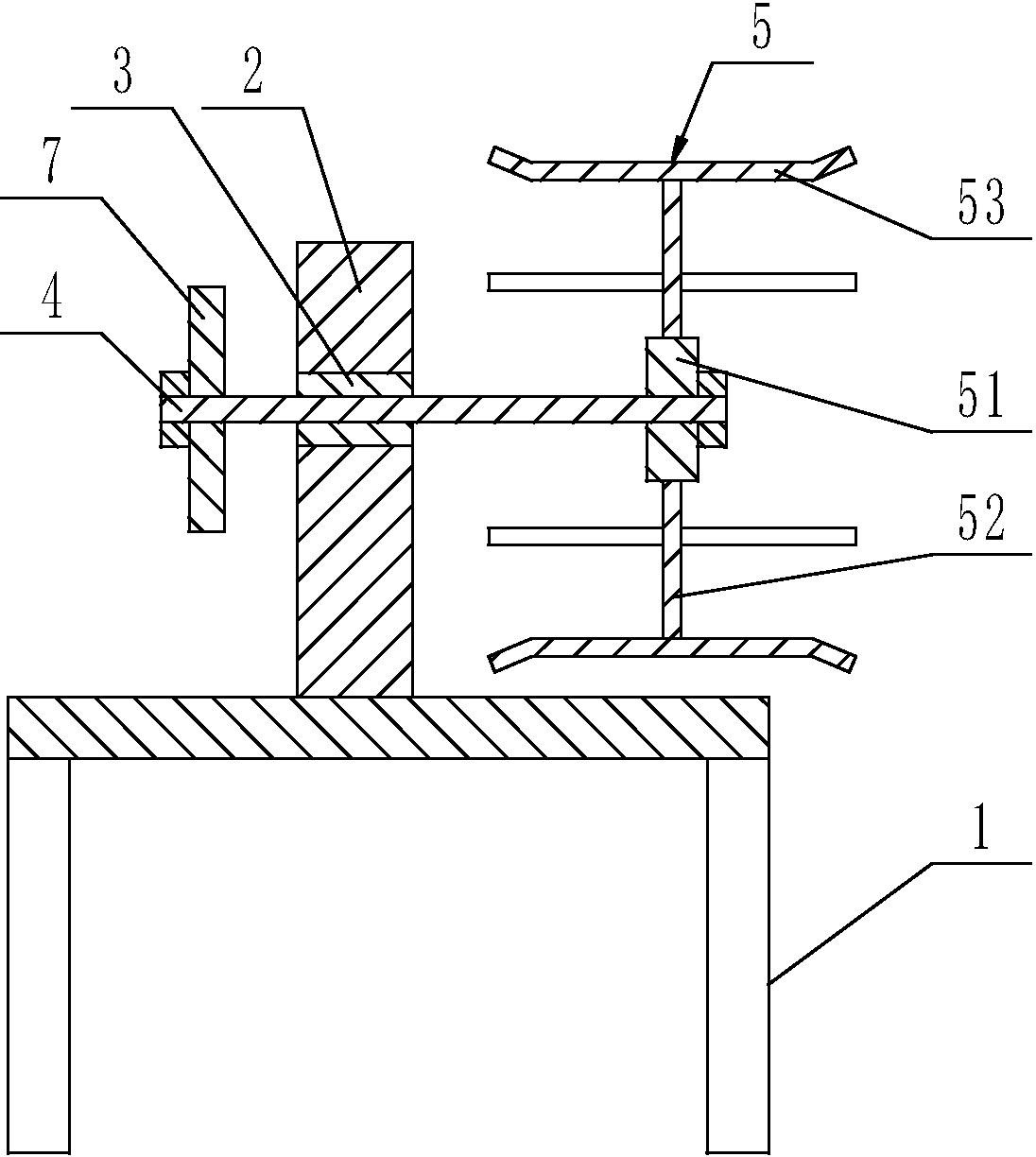

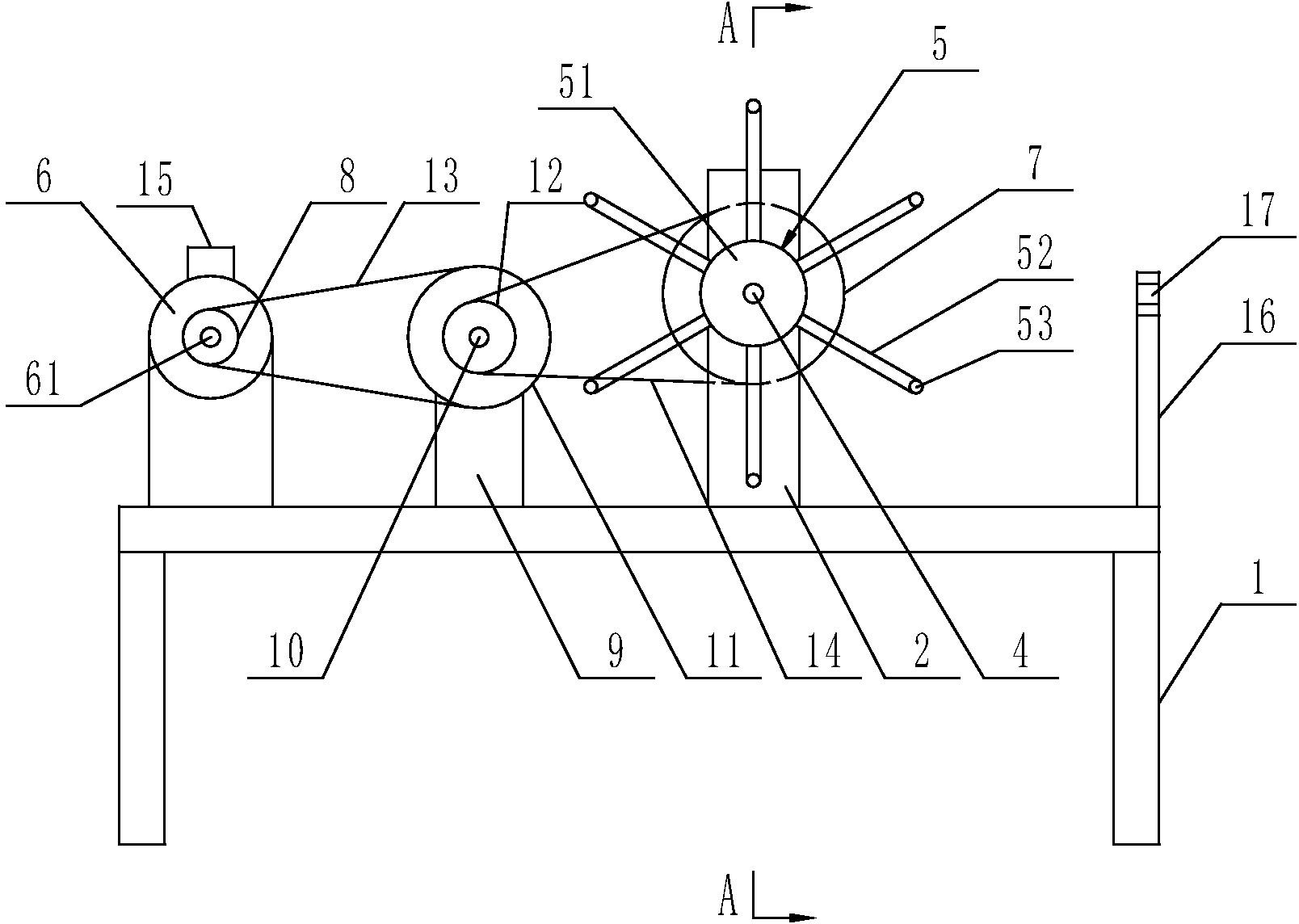

[0014] Such as figure 1 , figure 2 As shown, the wire stripping device includes a frame 1, the frame 1 is provided with a support seat 2, a bearing 3 is arranged in the support seat 2, a main shaft 4 is movably arranged in the bearing 3, and a wire stripping frame is arranged on the main shaft 4 5. The wire stripping frame 5 includes a stripping disc 51 fixed on the main shaft 4, six connecting rods 52 are arranged on the stripping disc 51 in the circumferential direction, and the ends of each connecting rod 52 are respectively arranged in the axial direction. Stripping rods 53, the two ends of every wire stripping rod 53 are all slightly tilted outwards, so that long filaments can be prevented from coming off from the stripping rod 53. The main shaft 4 is driven by a motor 6, the motor 6 is fixed on the frame 1, the main shaft 4 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com