Slag salvaging cylindrical drill for drilled pile

A technology of bored piles and slag barrels, which is applied in the direction of earthwork drilling, wellbore/well components, etc., which can solve the problems that drilling cannot continue, mud cannot circulate, and drilling speed is slow, so as to improve safety, quality and work efficiency , reduce engineering costs, and reduce the waste of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

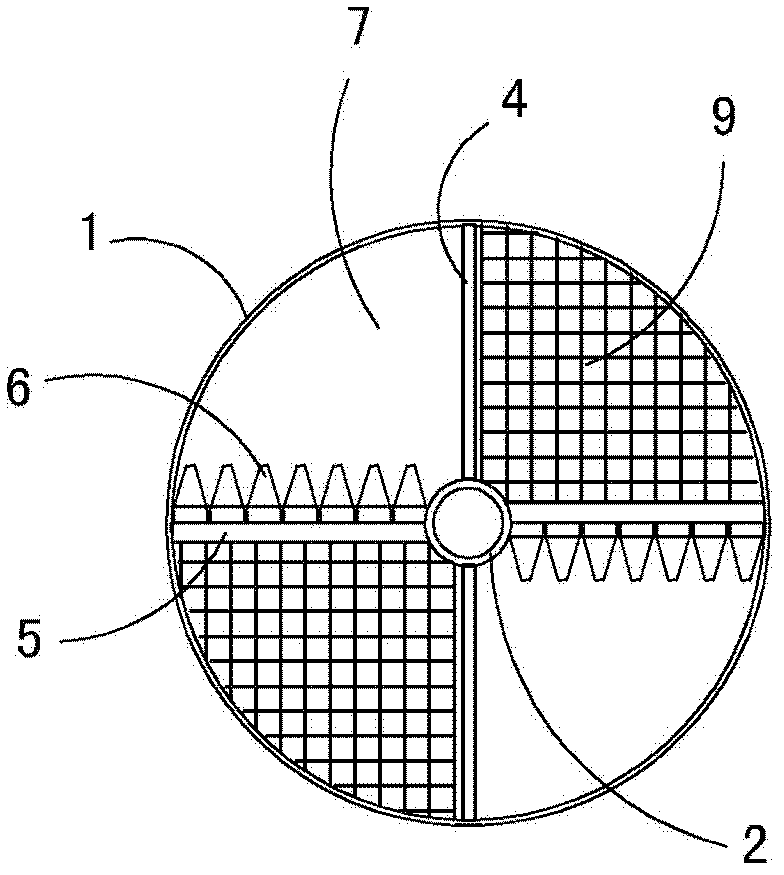

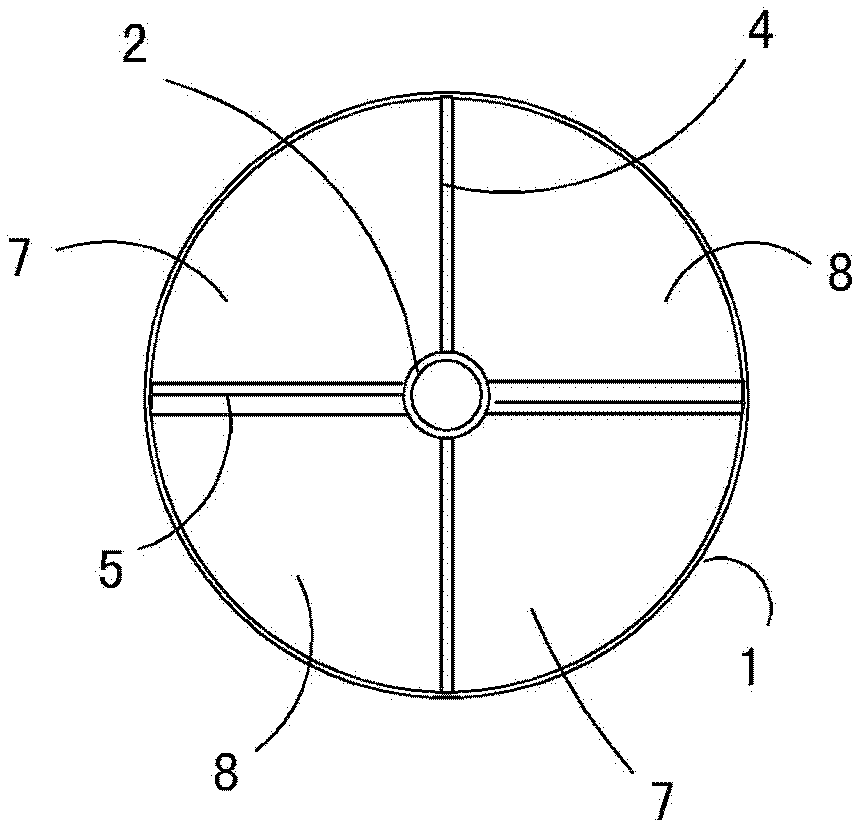

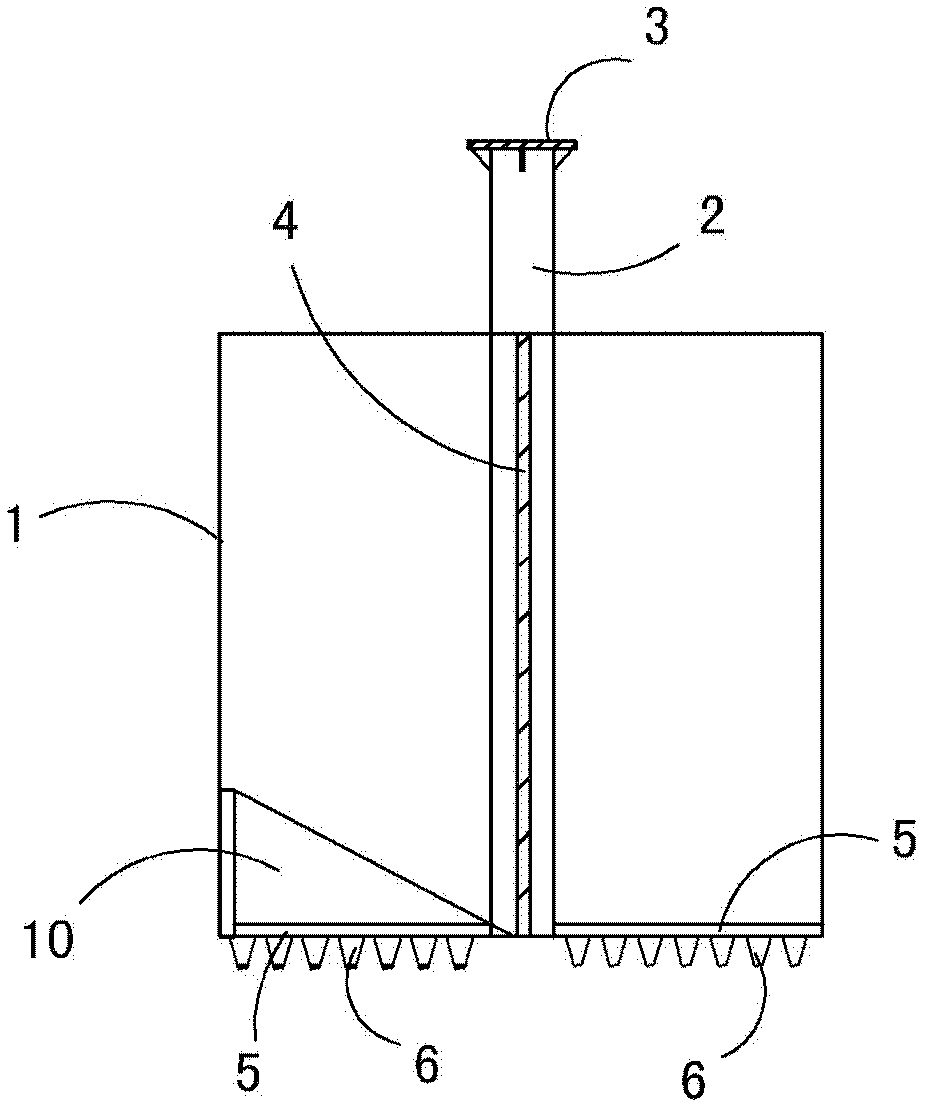

[0017] The drilling pile slag removal cylinder drill in this embodiment is provided with a cylinder body 1, and a drill pipe 2 is arranged at the central axis of the cylinder body 1, and the top end of the drill pipe 2 penetrates the top of the cylinder body 1 and is provided with a flange 3; The inside of cylinder body 1 is divided into semi-cylindrical cylinders on both sides by mediastinal plate 4; bottom steel beam 5 is set at the bottom of cylinder body 1 at the position where it crosses the bottom edge of mediastinal plate 4 in the shape of a “ten”, and the bottom steel beam Drilling teeth 6 are arranged at intervals on the top 5, and the semi-cylindrical cylinder is divided into a salvage bin 7 and a storage bin 8 with the bottom steel beam 5. The salvage bin 7 is an open sector, and the storage bin 8 is a fan covered by a steel mesh 9. District; the salvage bin 7 in the semi-cylindrical barrel on both sides is in the diagonal position.

[0018] image 3 and Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com