High voltage diode assembly tool and operation method thereof

A technology for high-voltage diodes and assembly fixtures, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and circuits. The effect of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

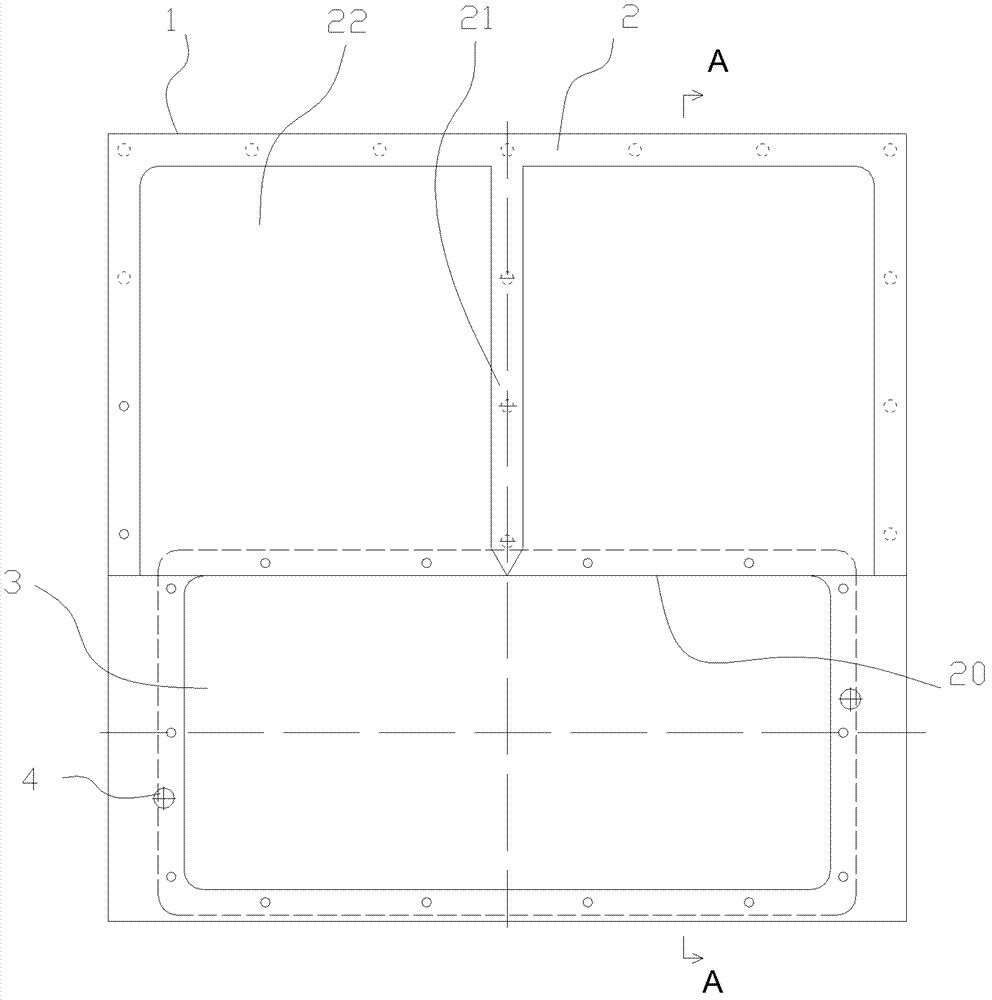

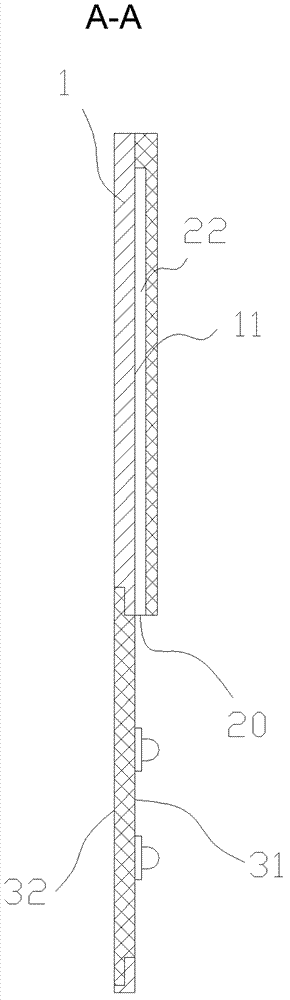

[0027] The present invention as Figure 1-5 As shown, it includes a chip chuck 5 and a conversion board, the conversion board includes a base plate 1 and a cover plate 2, the cover plate 2 is fixedly connected to the top surface of the base plate 1 as the working surface 11, and the cover plate 2. The area is smaller than the area of the top surface of the substrate 1, so that an exposed working surface portion 31 is left on the top surface of the substrate 1; a gap 22 is left between the cover plate 2 and the substrate 1, and the opening 20 of the gap faces The exposed working surface part 31 part; the height of the gap 22 is less than the width and length of the chip 6, so that the chip 6 will not turn over in the gap 22;

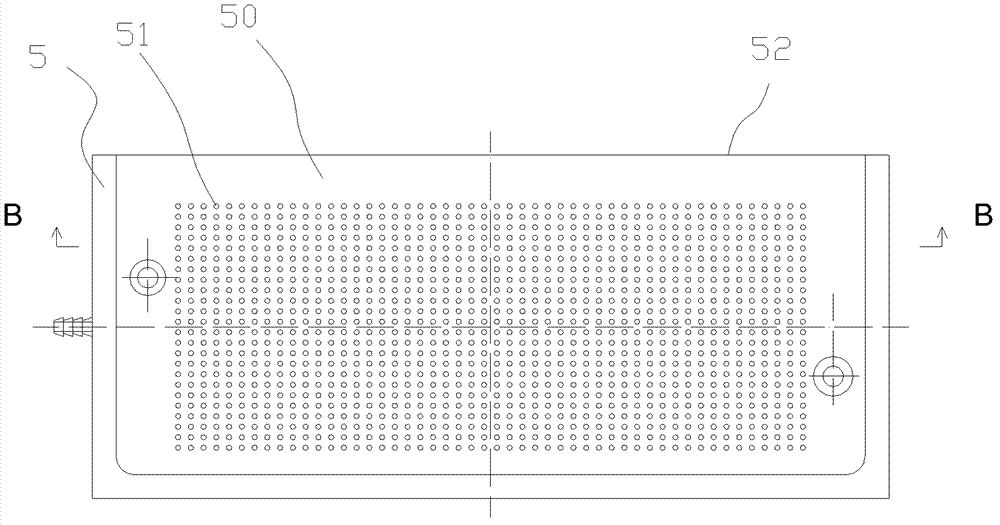

[0028] The chip chuck 5 has a shape matching the plane profile of the exposed working surface portion 31, and the surface of the chip chuck 5 facing the exposed working surface portion 31 is provided with a sinking surface 50, and the sinking surface 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com