Multifunctional soybean milk making machine

A soymilk maker and multi-functional technology, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of poor safety, high noise, and more bean dregs, and achieve the effects of good safety, low noise, and less bean dregs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

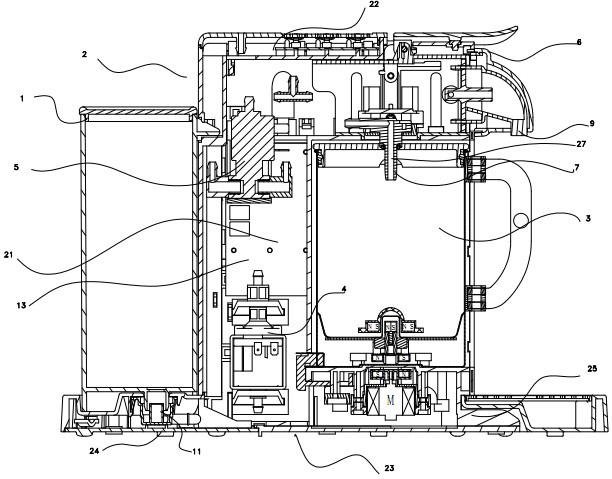

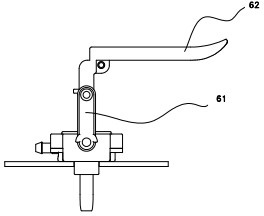

[0036] See attached Figure 1-4 , a multifunctional soy flour soy milk machine, comprising a water tank 1, a body 2, and a material cup 3. The fuselage 2 includes a fuselage main body 21, a machine head 22, and a fuselage base 23. A first extension 24 extends from one side of the fuselage base 23, and a second extension 25 extends from the other side. The water tank 1 is installed on the first extension. On the part 24, the second extension part 25 is used to place the external container, which is convenient for the external container to take water or soybean milk from the soybean milk machine. A water outlet joint 11 is provided at the bottom of the water tank 1 , the water outlet joint 11 is connected to one end of the water pump 4 , the other end of the water pump 4 is connected to the solenoid valve 5 , and the solenoid valve 5 is electrically connected to the control unit 13 . A lever locking device 6 is installed on the machine head 22. The lever locking device 6 includ...

Embodiment 2

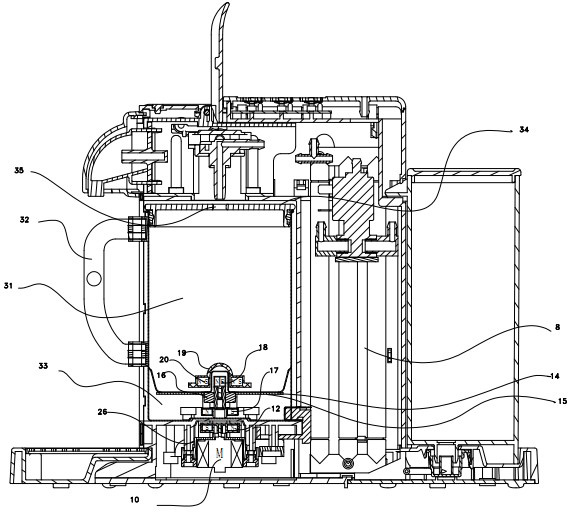

[0043] See attached Figure 5-6 , and the difference from the first embodiment is that in the second embodiment, the machine head 22 is rotatably connected to the main body 21 of the fuselage, the machine head 22 rotates upward to a certain height, and the water injection joint 11 leaves the cup body 31. At this time, the material cup 3 can be taken out. During work, the material cup 3 is put into the base, and the machine head 22 is rotated so that the water injection joint 11 enters the cup body. Others are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0045] See attached Figure 7-8 , different from Embodiment 1, in Embodiment 3, the machine head 22 can be moved up and down and installed on the body 21 of the fuselage, the stirring device includes a motor 10 installed on the base of the fuselage, and the output shaft of the motor 10 is provided There is a first clutch part 40, and the material cup 3 includes a cup body 31 for holding materials, a chamber 33 located at the bottom of the cup body, a transmission shaft 41 is arranged in the chamber 33, and one end of the transmission shaft 41 passes through a hole provided at the bottom of the cup body 42 extends into the cup body, the cup body 31 and the transmission shaft are sealed by a seal 43, the upper end of the transmission shaft 42 is provided with a stirring cutter connector 44, and the stirring cutter 45 is detachably connected to the cutter connector 44, and the transmission The lower end of the shaft 41 is provided with a second clutch part 46 compatible with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap