Perilla-added cold beverage and preparation method thereof

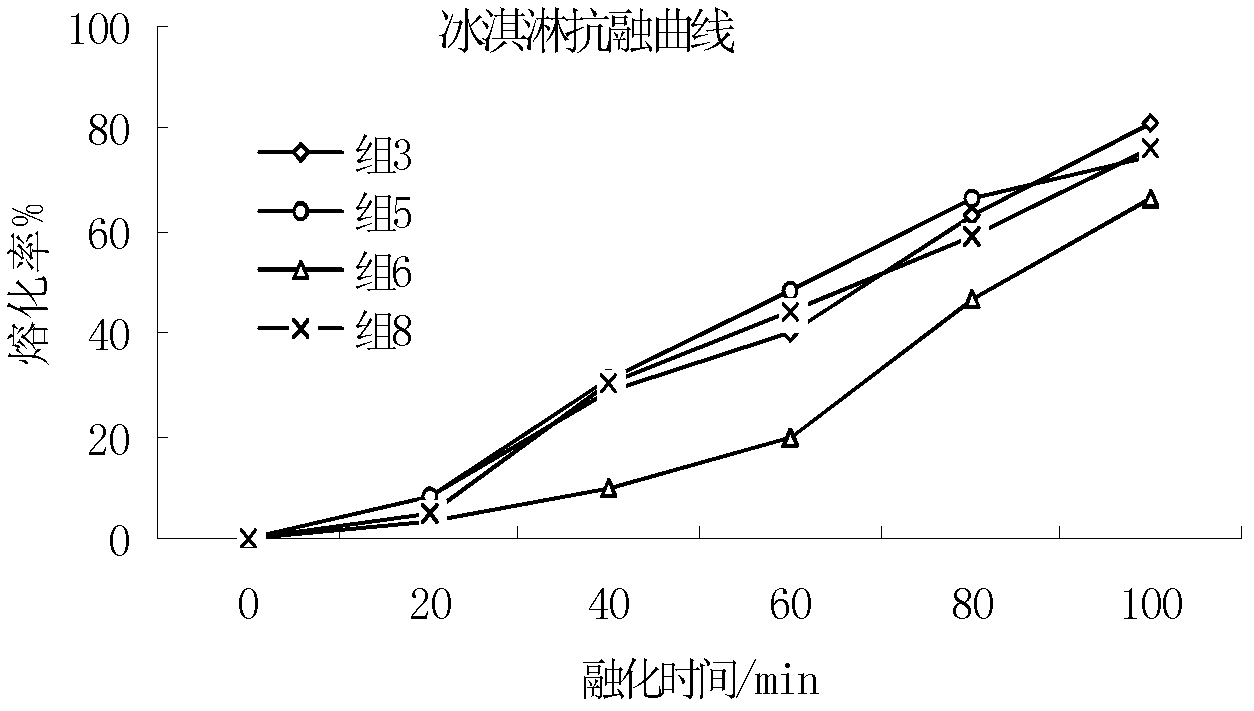

A technology of frozen drinks and perilla, applied in frozen sweets, food science, applications, etc., can solve the problems of not being suitable for perilla ice cream and affecting the melting resistance of ice cream, enriching categories, filling market gaps, and solving poor melting resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The processing of embodiment 1 perilla

[0032] ①Preparation of perilla leaf juice dry powder: wash, stir, squeeze, separate and filter the picked fresh perilla leaves, and then use freeze-drying method or instant drying method to obtain perilla leaf juice dry powder from the light-colored clear liquid .

[0033] ②Preparation of perilla seed oil: After cleaning and washing the perilla seeds, soak them in water to make the water content of the perilla seeds reach 5-20%, and then steam and fry them for 5-30 minutes at a temperature of 80 -130°C, and then press the oil in an oil press that has been preheated to 80-120°C to obtain perilla seed oil with high oil yield and fragrance.

Embodiment 2

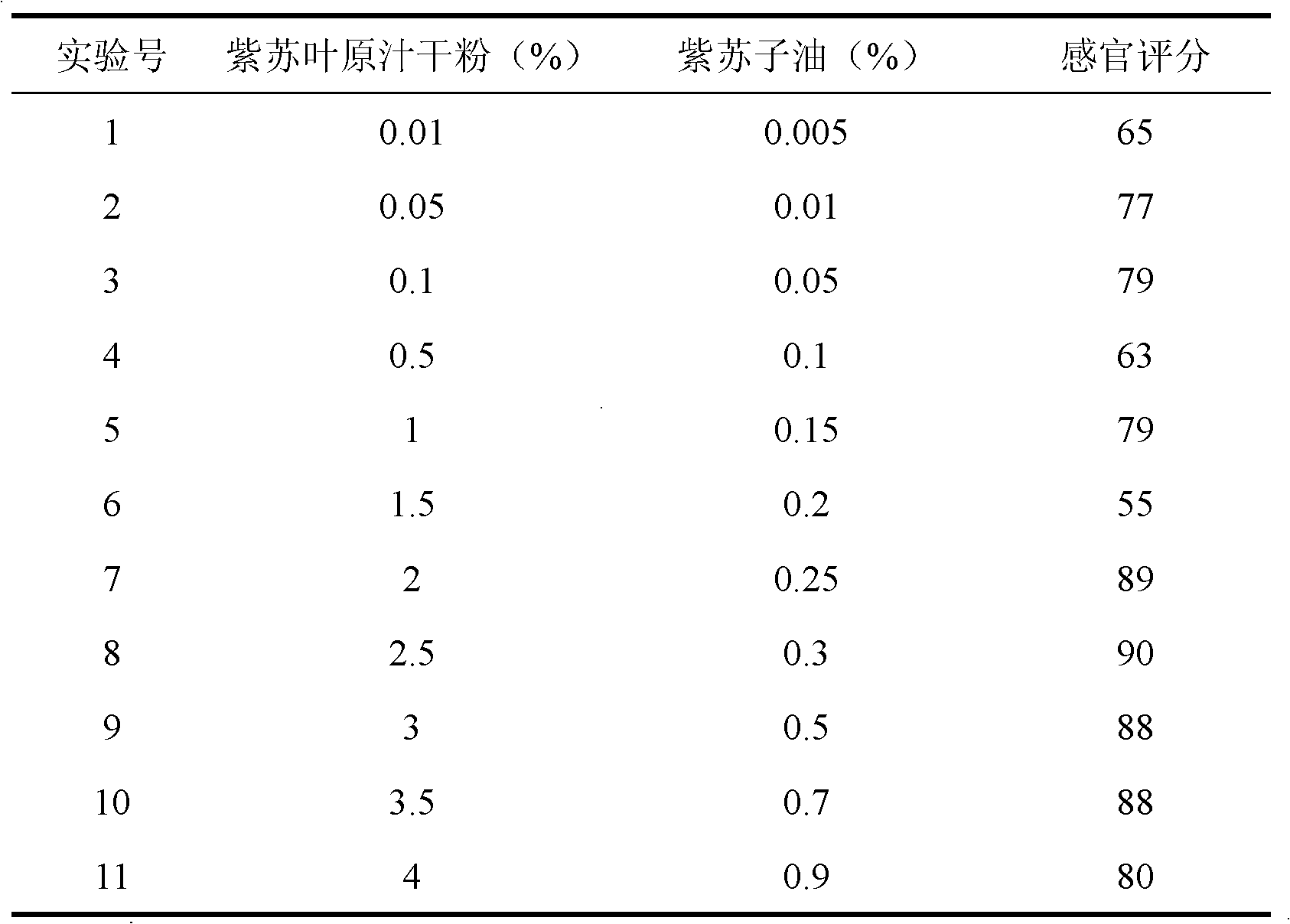

[0034] Embodiment 2 prepares the frozen drink that adds perilla

[0035] The raw materials include by weight: 12% of white granulated sugar, 5% of malt syrup, 10% of whole milk powder, 6% of vegetable oil, 2% of perilla leaf juice dry powder, 0.25% of perilla seed oil, 0.4% of edible stabilizer (melon Seoul gum 0.1%, xanthan gum 0.1%, locust bean gum 0.1%, carrageenan 0.1%), monoglyceride 0.1%, the balance of water.

[0036] Preparation:

[0037] Raw material pretreatment: mix the edible stabilizer and white sugar evenly, and melt the fat in advance;

[0038] Mixing: According to the order of liquid first, then powder, fully mix the raw materials obtained in step 1) with other raw materials, and the mixing temperature is 60°C;

[0039] Preheating: heat the mixed material liquid from the mixing temperature to 70-75°C and set aside;

[0040] Homogenization: Pass the preheated material liquid through a high-pressure homogenizer, and after homogenization, a fully mixed and stab...

Embodiment 3

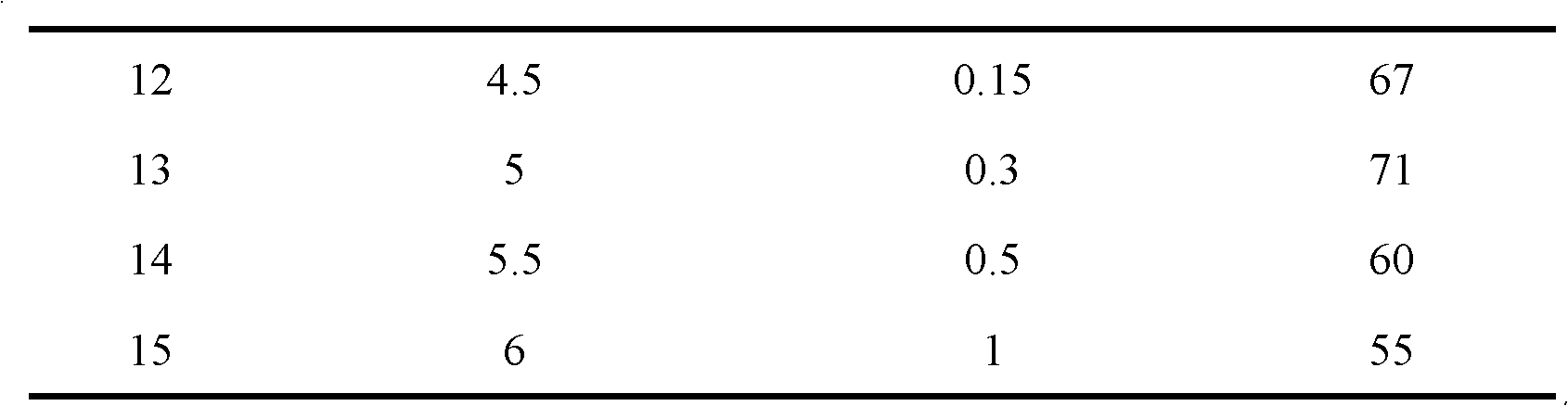

[0045] Embodiment 3 prepares the frozen drink that adds perilla

[0046] The raw materials include by weight: 14% white granulated sugar, 7% maltose syrup, 12% whole milk powder, 8% vegetable oil, 4% perilla leaf juice dry powder, 0.9% perilla seed oil, 2.0% edible stabilizer (melon Seoul gum 0.5%, xanthan gum 0.5%, locust bean gum 0.5%, carrageenan 0.5%), monoglyceride 0.5%, water balance.

[0047] Preparation:

[0048] Raw material pretreatment: mix the edible stabilizer and white sugar evenly, and melt the fat in advance;

[0049] Mixing: According to the order of liquid first, then powder, fully mix the raw materials obtained in step 1) with other raw materials, and the mixing temperature is 60°C;

[0050] Preheating: heat the mixed material liquid from the mixing temperature to 70-75°C and set aside;

[0051] Homogenization: Pass the preheated material liquid through a high-pressure homogenizer, and after homogenization, a fully mixed and stable ice cream material liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com