Pulsed blowing ash-removal control system of large-scale bag-type deduster, and control method therefor

A technology of bag dust collector and pulse injection, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, etc. Signal chaining is not tight enough to achieve the effect of ensuring a safe state, ensuring intelligence and rationalization, and reasonable chaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

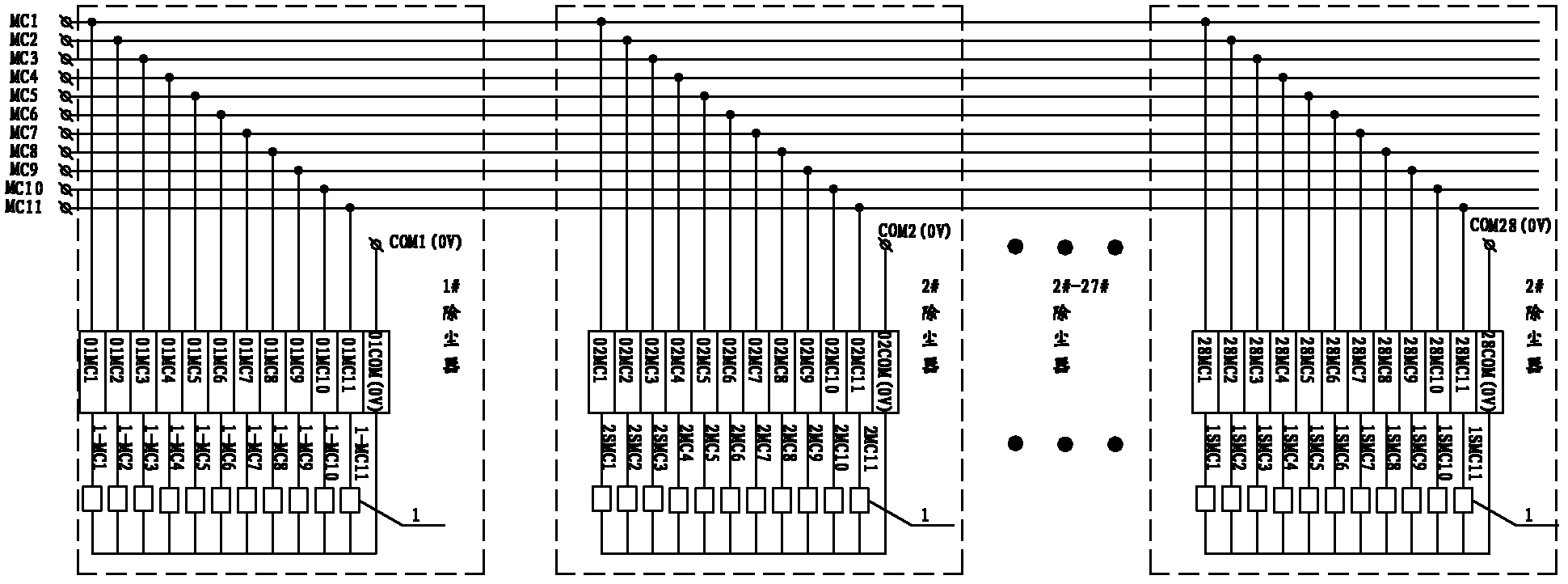

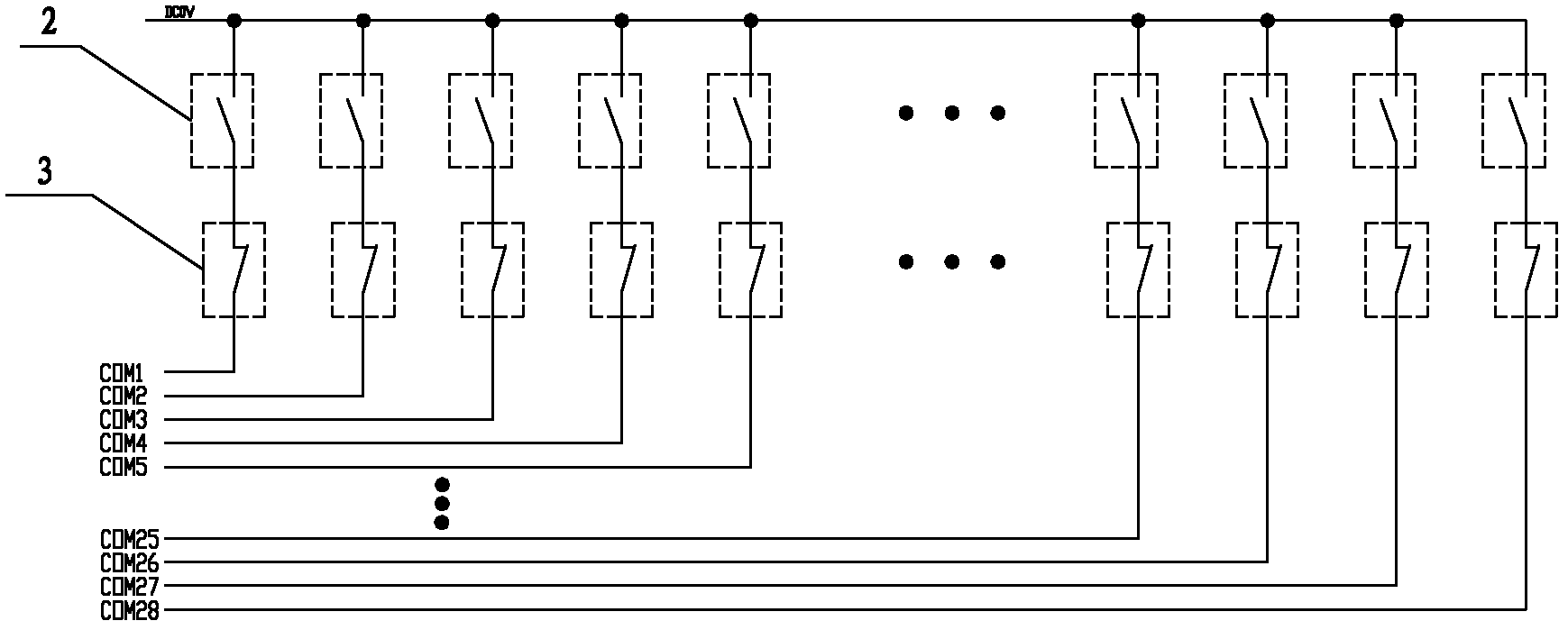

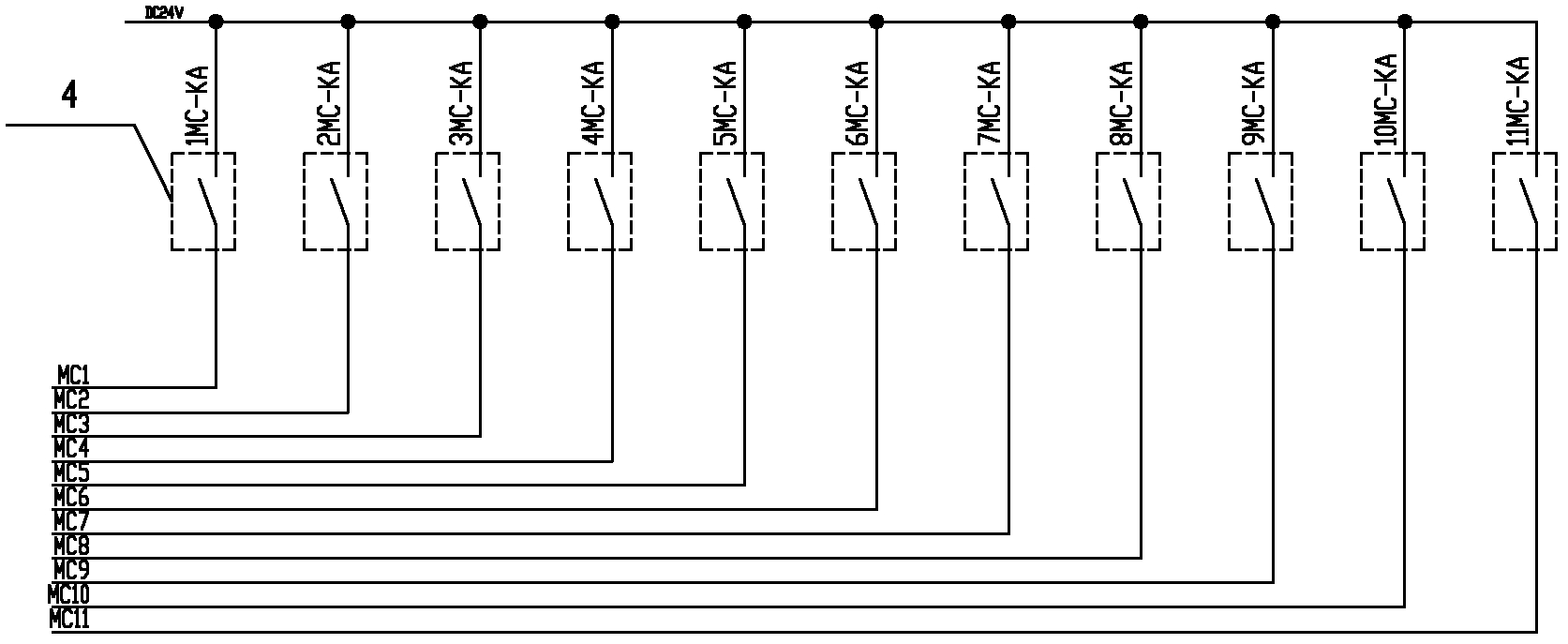

[0033] Aiming at the deficiencies of the existing matrix control circuit and dust removal control strategy, the present invention designs a new type of matrix expansion circuit for the pulse injection system of a large bag filter, and provides an intelligent control strategy for the injection system closely integrated with it, Realize the automatic dust removal of the dust removal system and the spare warehouse jump to ensure the intelligence and rationalization of the dust removal process; realize the perfect centralized maintenance function and ensure the reasonable switching of various operation and maintenance modes; realize the rationalization of dust collectors and fans Interlocking ensures that the dust collector works in a safe state.

[0034] The scheme adopted in the present invention is: to build a new type of matrix expansion circuit, and correspondingly develop a pulse jet ash removal control strategy with the functions of automatic ash removal, spare warehouse jum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com