Hydraulic cone crusher

A cone crusher, hydraulic technology, applied in grain processing and other directions, can solve the problems of low production efficiency of cone crusher, complex structure of cone crusher, unsuitable for popularization and use, etc., and achieves easy disassembly and maintenance, long maintenance period and productivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

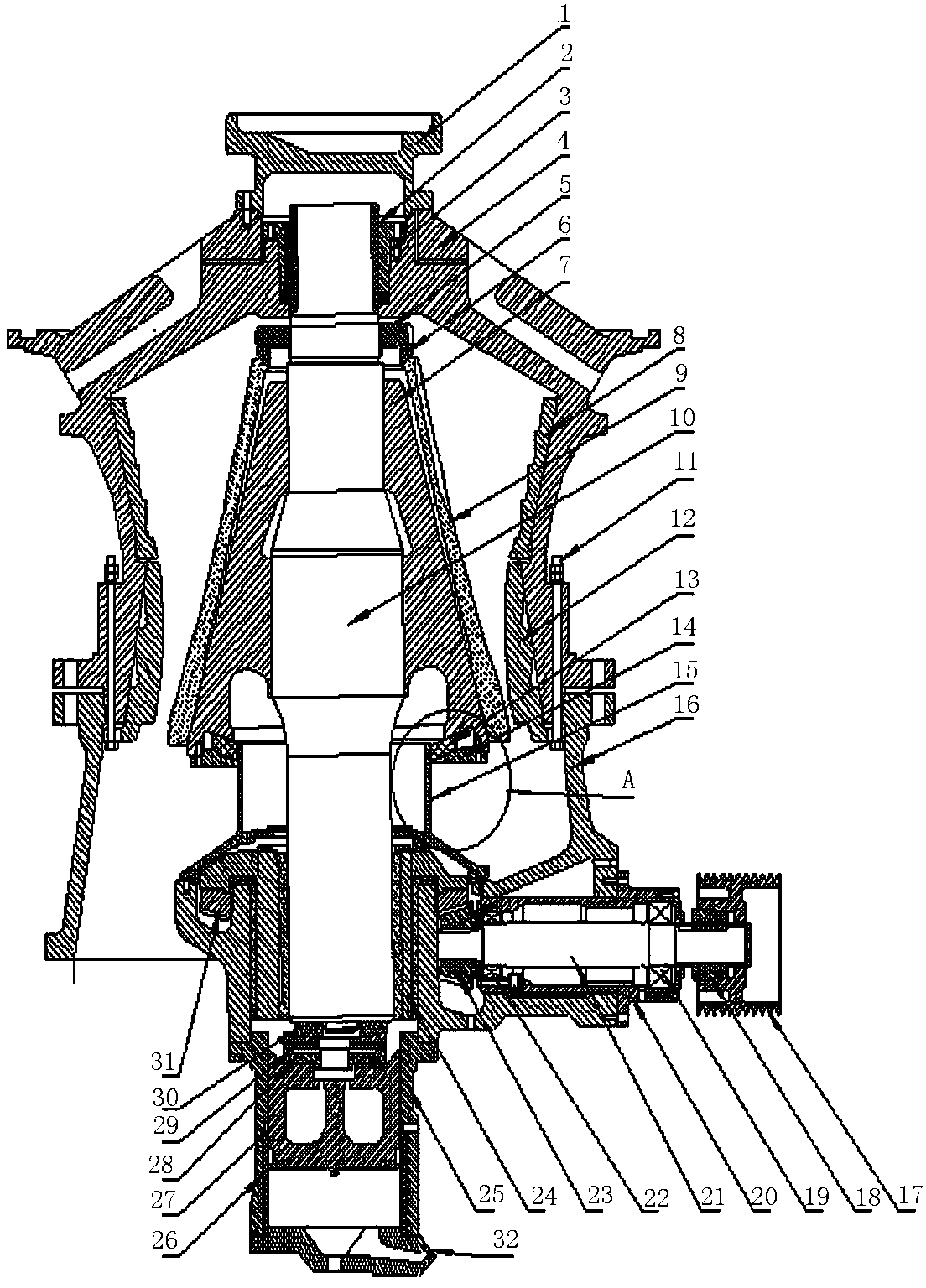

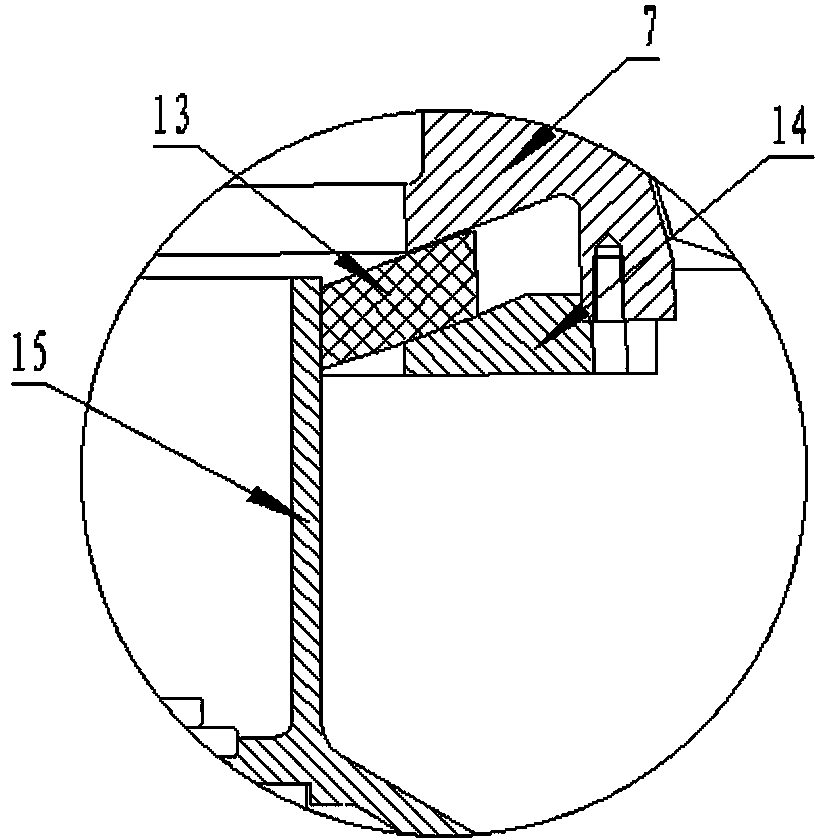

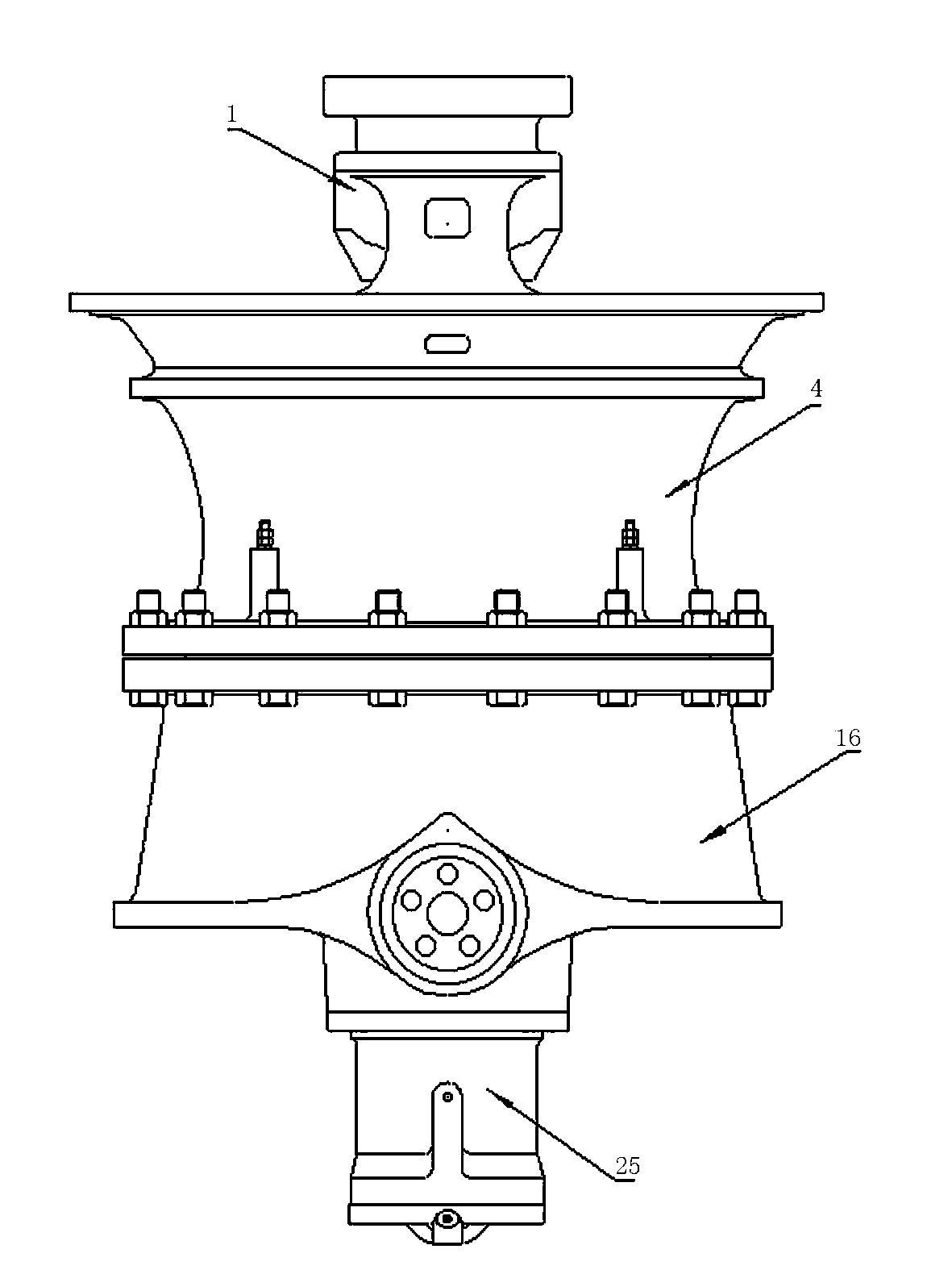

[0017] Attached below Figure 1-3 The present invention is described in further detail with the specific embodiment:

[0018] The hydraulic cone crusher includes an upper frame 4 and a lower frame 16, the top of the upper frame 4 is connected to the distribution tray 1, and the main shaft 10 is arranged under the distribution tray 1, and the top of the main shaft 10 is matched with the main shaft sheath 2 and the top bearing 3. The main shaft 10 is covered with a body 7, and a body liner 9 is arranged outside the body 7, and the angle between the body liner 9 and the horizontal direction is 71°. The top of the body liner 9 is provided with a cutting ring 6 , and the top of the cutting ring 6 is a body liner locking nut 5 . The inside of the upper frame 4 is directly connected with the upper frame guard plate 8 and the upper frame liner plate 12 through six M30 upper frame liner fixing bolts 11, and the upper frame guard plate 8 is located above the upper frame liner plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com