Composite steel plate and manufacturing method for same

A technology of composite steel plate and manufacturing method, which is applied to manufacturing tools, chemical instruments and methods, non-electric welding equipment, etc., can solve the problems of stainless steel surface corrosion, liquid magnesium leakage, brittleness and peeling off of oxide film, etc., so as to reduce leakage and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

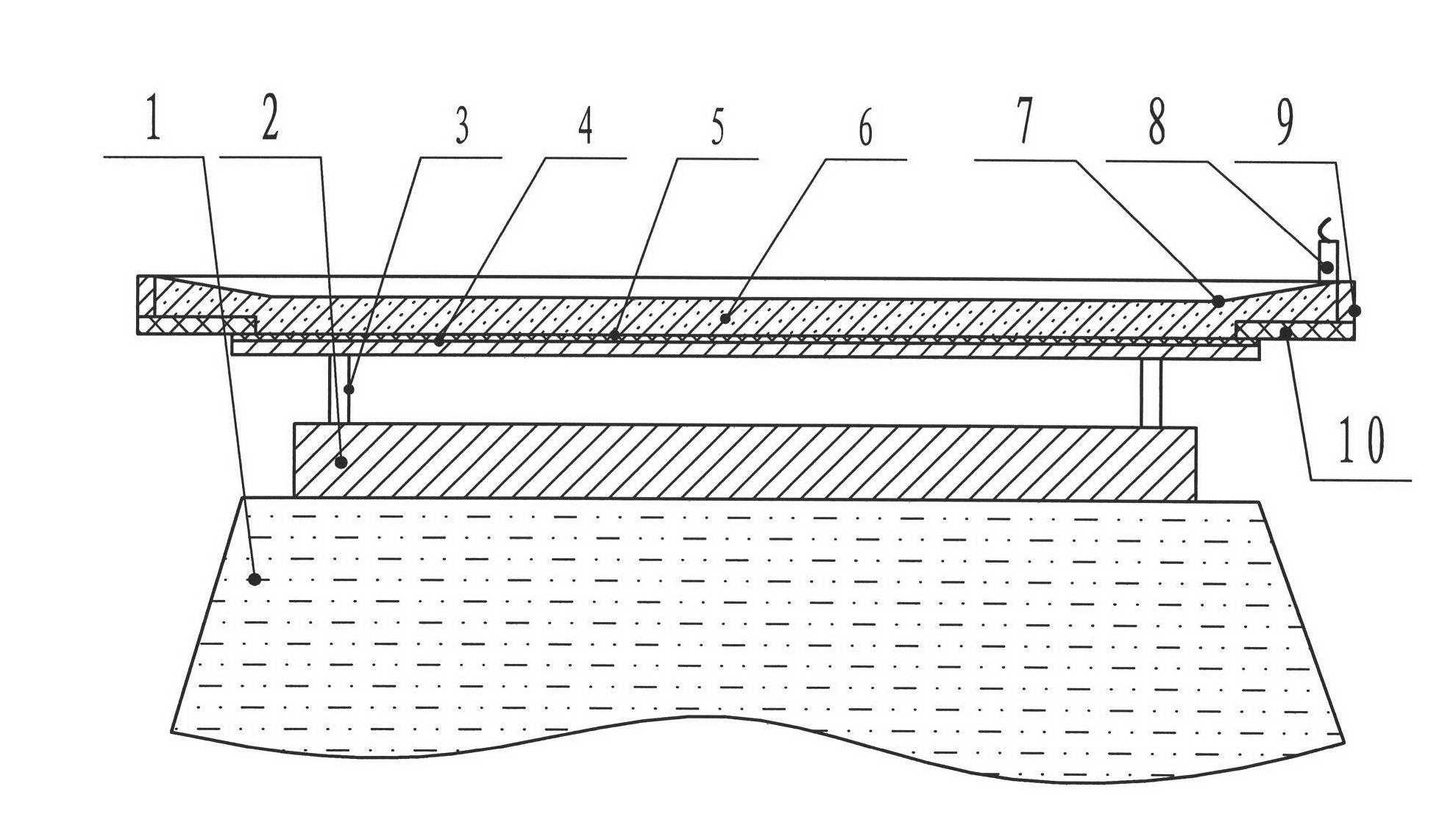

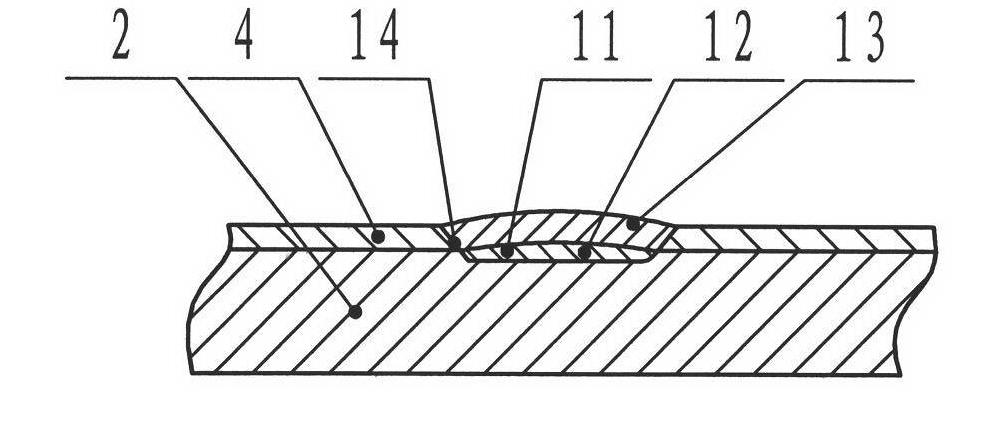

[0036] The specific embodiments of the composite steel plate and the manufacturing method thereof will be described in detail below in conjunction with the embodiments and the drawings, but the specific embodiments of the composite steel plate and the manufacturing method thereof are not limited to the following embodiments.

[0037] Composite steel plate example

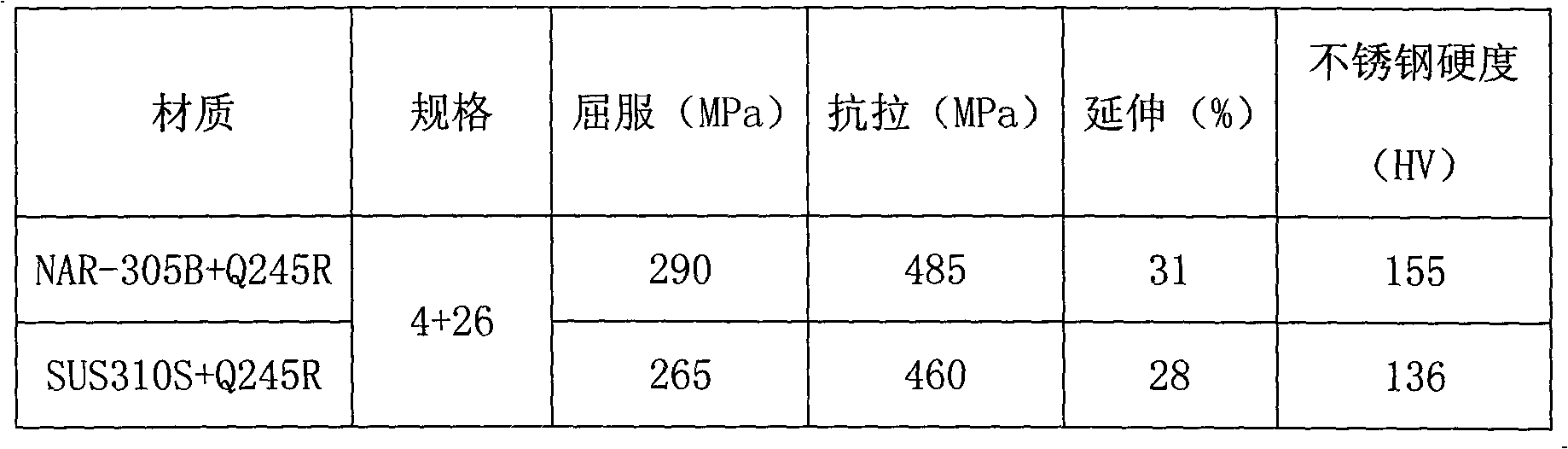

[0038] In this embodiment, the Q245R substrate in the national standard GB713 and the composite board are welded together. The length of the finished substrate is 6050mm, the width is 1050mm, and the thickness of the substrate is 26mm. The length and width of the composite board are equal to those of the substrate. The length is also 6050mm, the width is 1050mm, and the thickness of the composite plate is 4mm; it is characterized in that the composite plate is NAR-305B stainless steel of Japanese stainless steel standard JIS G 4305.

[0039] Manufacturing method embodiment

[0040] This example manufactures the composite st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com