Pretreatment technology of atmospheric superheated steam for improving wood dimension stability

A dimensionally stable, superheated steam technology, used in wood processing, wood processing details, wood processing appliances, etc., can solve problems such as human harm and environmental pollution, and achieve the effect of reducing water absorption, no chemical pollution, and increased plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

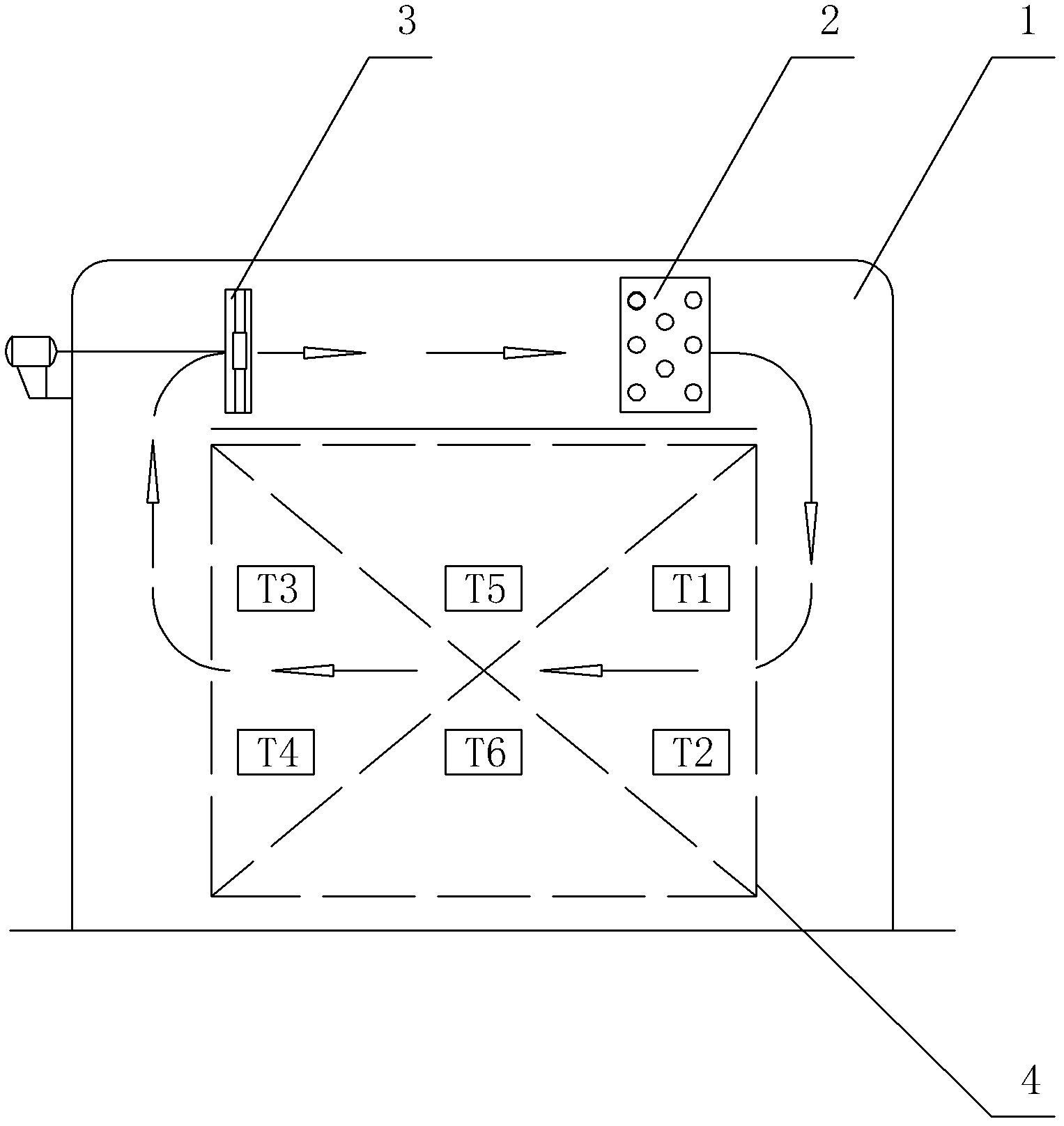

[0029] see figure 1 , a pretreatment process of wood superheated steam, the core of which is to complete the pretreatment process by controlling the values and mutual relations of the temperature of the incoming pile, the temperature of the outgoing pile, and the temperature of the wood core.

[0030] 1. Palletizing

[0031] According to the size specifications of the wood to be processed, the materials to be processed are coded into unit material piles of a certain size, and the unit material piles are loaded into the pretreatment equipment 1 with a forklift, and arranged to measure the temperature of the incoming pile, the temperature of the outgoing pile, and the temperature of the pile. sensor for wood core temperature, then close the kiln door.

[0032] 2. Process

[0033] Start the circulating fan 3 and the heating system 2 to preheat the woo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com