Production method of nitro compounds by tubular continuous nitrification reaction

A nitro compound and nitration reaction technology, which is applied in the field of continuous nitration reaction to produce nitro compounds, can solve the problems of concentration distribution in the superheated kettle, high water and alkali consumption, and reduce heat transfer coefficient, etc. Effective production time, low energy and material consumption, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

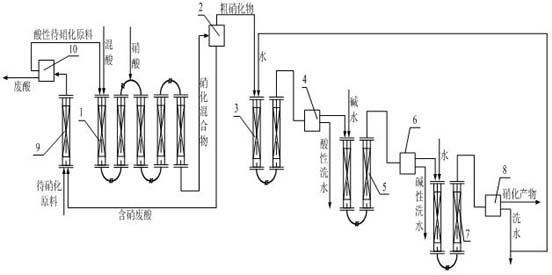

Embodiment 1

[0027] Tubular continuous nitration reaction method, the equipment used includes twelve tubular nitrification reactors 1, nitrification mixture separators 2, and six tubular primary scrubbers 3, primary washing separators 4, and six serially used tubular nitration reactors. Two sets of tubular caustic scrubbers 5, caustic wash separators 6, four sets of tubular secondary scrubbers used in series 7, two-stage water washing separators 8, tubular nitrate-containing waste acid extraction reactors 9, waste acid With acid raw material to be nitrated separator 10, connecting pipelines and various accessories. The tubular continuous nitration reaction method includes: excessive nitric acid is used in the ratio of raw materials. The mixed acid composed of the acidic raw material to be nitrified, nitric acid, sulfuric acid, and water from the separator 10 of waste acid and acidic raw material to be nitrated enters the nitrification reactor 1 while flowing, mixing, reacting, and transferr...

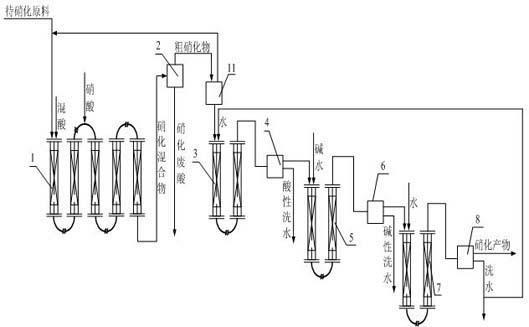

Embodiment 2

[0029] The second embodiment is basically the same as the first embodiment. The difference is that an acid phase (with waste acid containing nitric acid between the sections) and an organic phase (the raw materials to be nitrated and part of the nitrification reactor) are added between the fifth nitration reactor 1 and the sixth nitration reactor. Nitration product) separator, the separated acid phase increases the concentration of nitric acid and then merges with the separated organic phase into the sixth nitration reactor 1.

Embodiment 3

[0031] The third embodiment is basically the same as the first embodiment. The difference is that nitric acid is added between the fourth and fifth nitrification reactor 1 and between the eighth and ninth nitration reactor 1 to change the acid phase. Acid) the concentration of nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com