Fine pressure regulation type pneumatic pressurization cradle

A technology of pneumatic pressurization and cradle, applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of cumbersome installation procedures, attenuation of cradle pressure, inconsistent tightening force, etc., to reduce the installation workload, The effect of reducing labor intensity and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structure and working principle of the fine-tuning pneumatic pressurized cradle according to the present invention will be further described below in conjunction with the accompanying drawings.

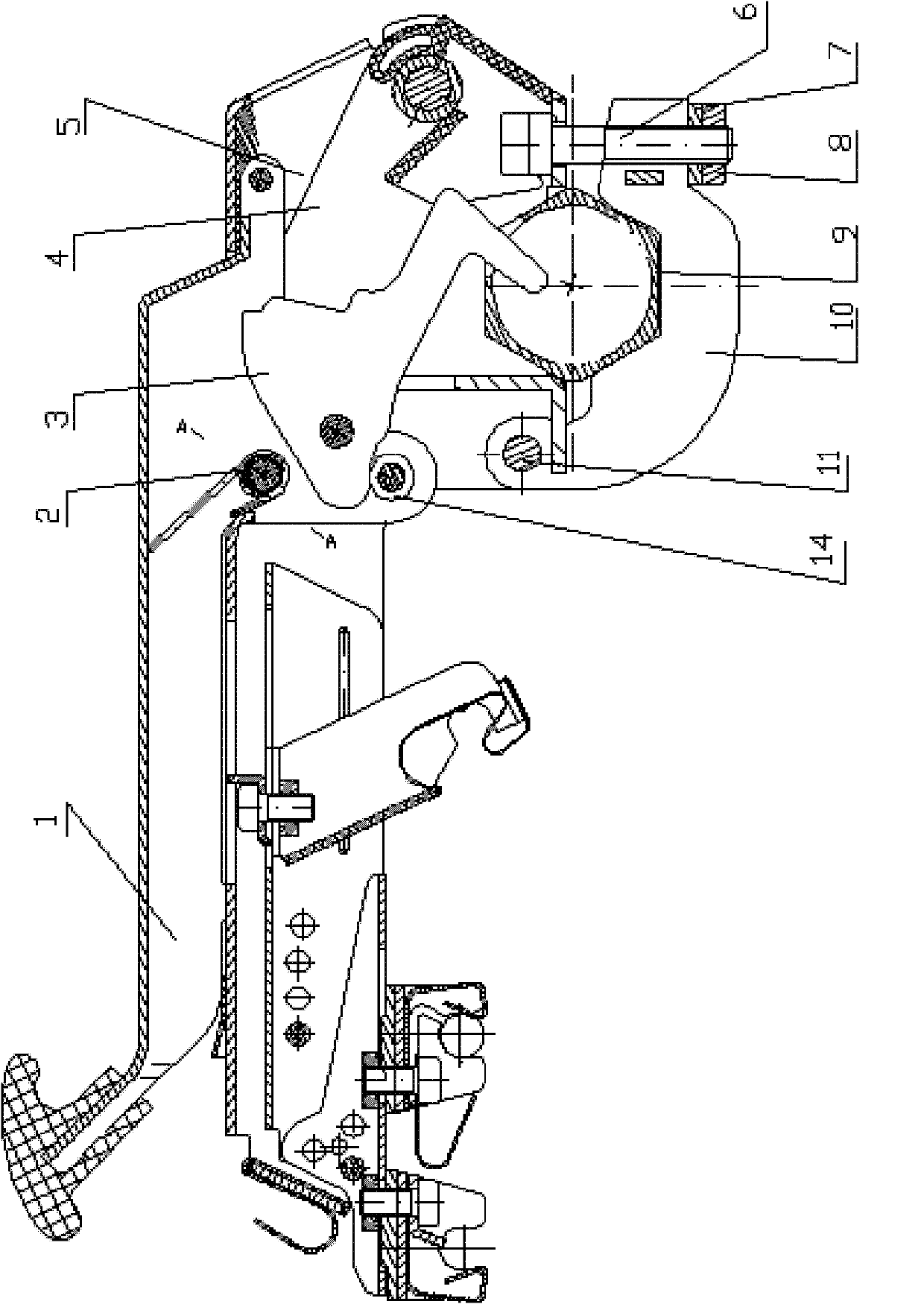

[0017] In this embodiment, the structure of the fine-tuning pneumatic pressurized cradle is as follows figure 1 As shown, it includes a cradle housing 5, a handle 1, a fixed card 4, a clamping card 10, a roller 14, a pressure transmission crank 3 and an eccentric pin assembly for pressure regulation.

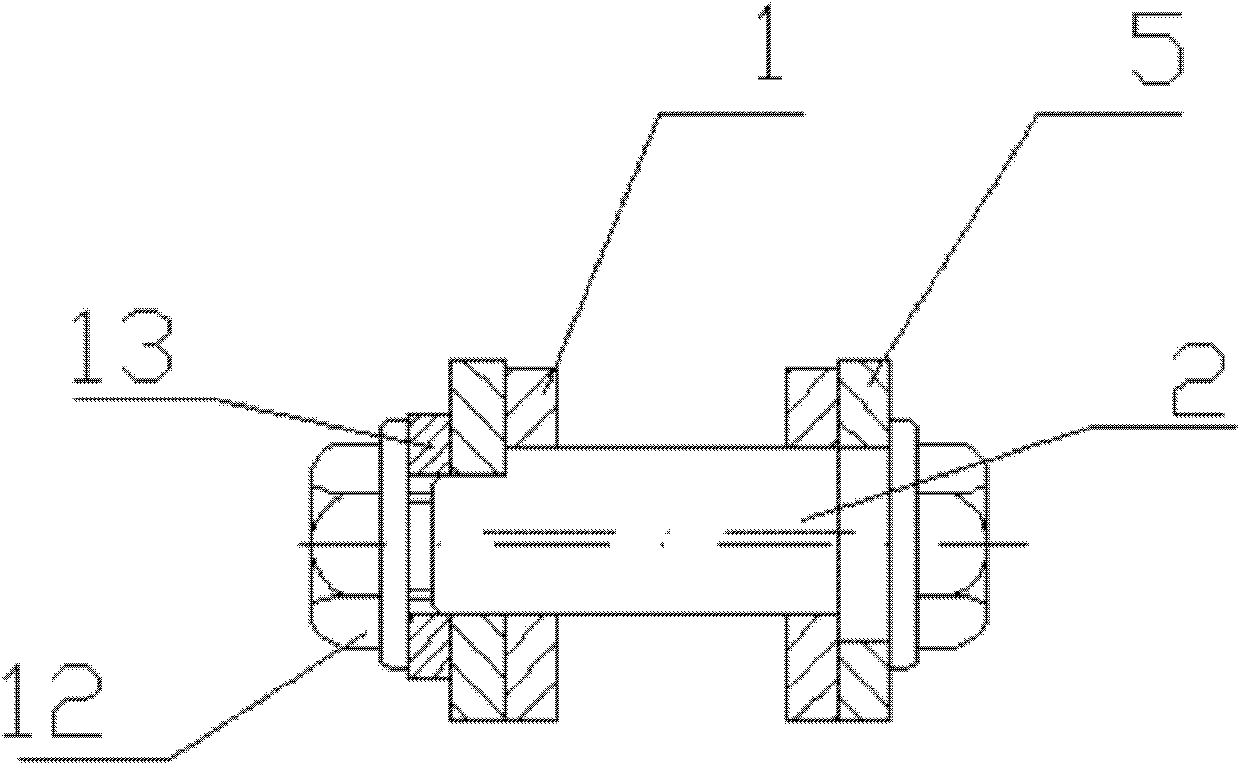

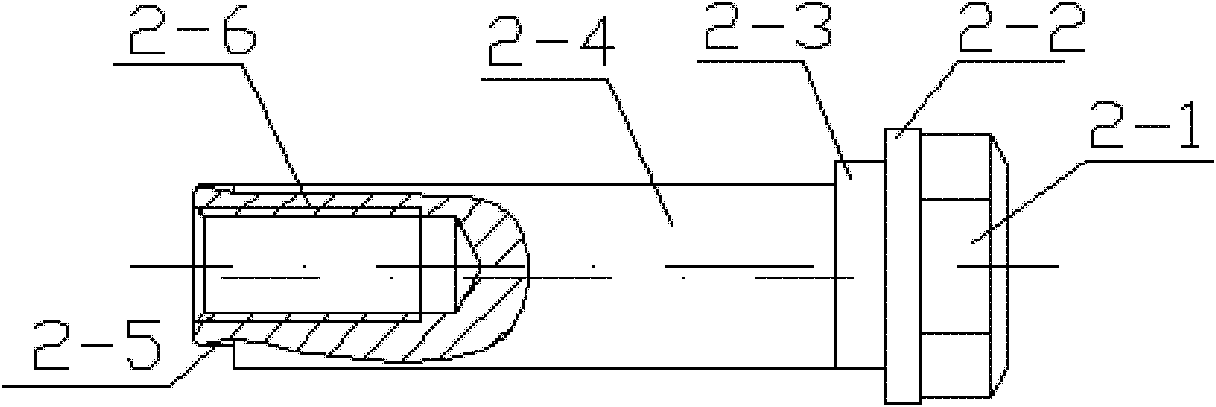

[0018] The structure of the eccentric pin assembly is as follows figure 2 As shown, it consists of eccentric pin 2, spring washer 13 and tightening screw 12. The structure of eccentric pin 2 is as follows image 3 As shown, the pin head 2-1, the combined washer 2-2, the first cradle shell hole matching section 2-3, the handle hole matching section 2-4 and the second cradle shell hole matching section 2- 5 components, the end of the second cradle shell hole matching sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com