Mechanical-hydraulic hybrid loading and automatic compensation type belt-type press and method

A hybrid loading and automatic compensation technology, applied in the field of diamond presses, can solve the problems of unstable pressure and difficult detection of mechanical transmission loading pressure, and achieve the effects of precise pressure and temperature control, reducing instability problems, and high transmission accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and embodiments.

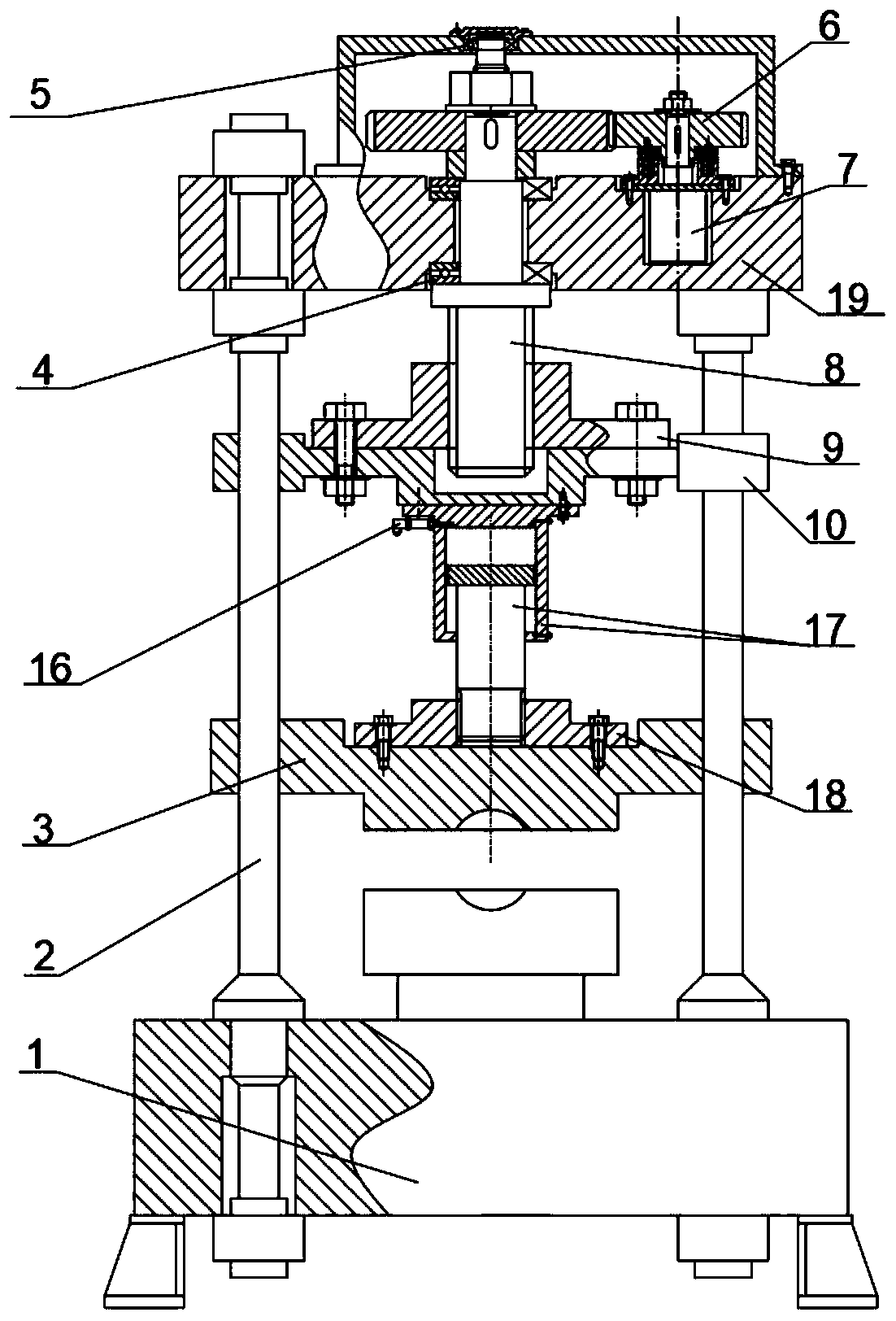

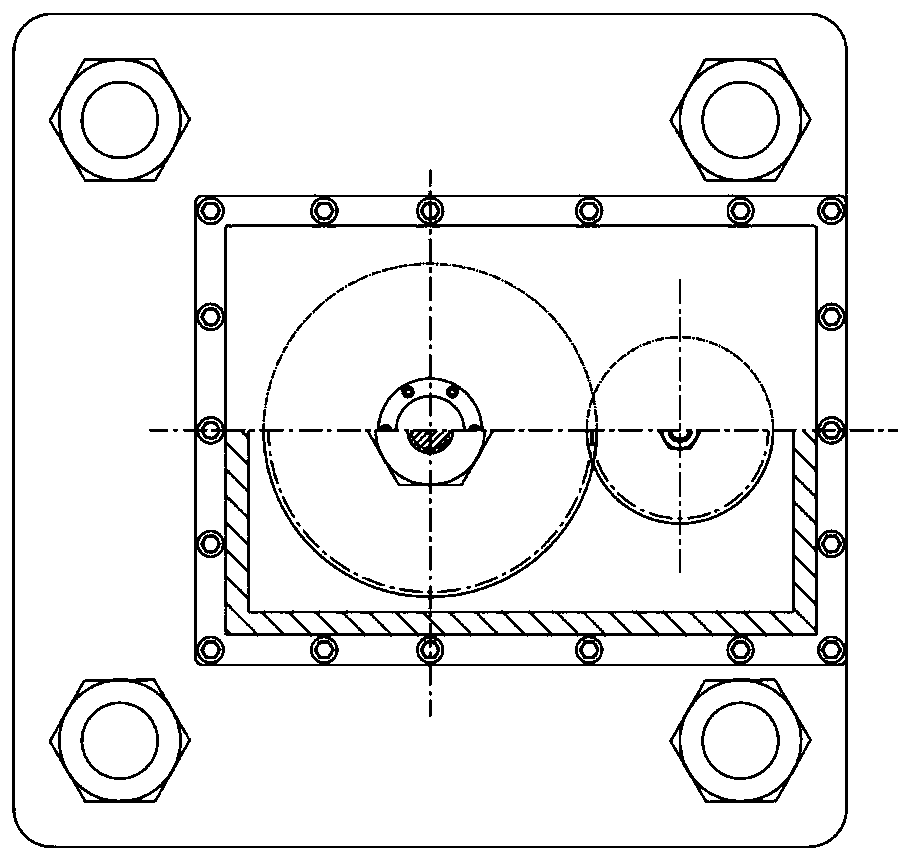

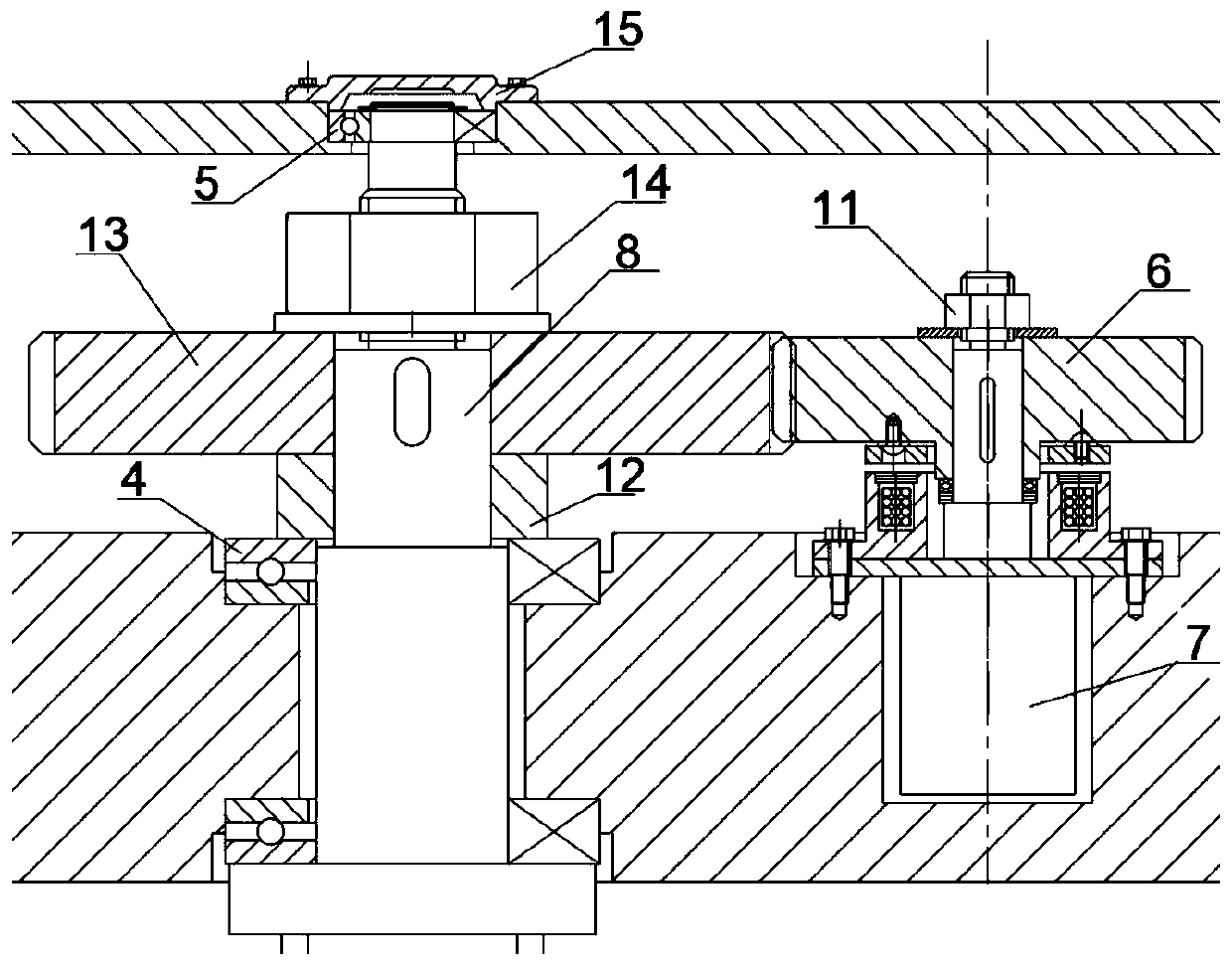

[0031] specific implementation, such as figure 1 and figure 2 As shown, the double-sided pressing machine includes a frame 1, a column 2, a lower pressure block 3, a transmission gear 6, a forward and reverse rotation motor 7, a main screw 8, a main nut 9, an upper pressure block 10, a driven gear 13, and a pressure sensor. 16. Hydraulic cylinder 17, threaded flange 18 and upper beam 19.

[0032] like figure 1 As shown, an upper beam 19 is fixed directly above the frame 1, and the upper beam 19 is fixedly connected to the frame 1 through a plurality of surrounding columns 2, and four columns are used in the specific implementation; the central hole of the upper beam 19 rotates through a thrust ball bearing 4 The main screw 8 is set, and the upper beam supports the main screw 8 through the thrust ball bearing 4. The main screw is provided with a shaft,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com