Sliding cabin type multilevel damper equipped with power consumption and tuning particles

A particle damper and damper technology, which is applied to building components and anti-vibration, can solve the problems of limited collision energy consumption, poor multi-dimensional control effect, poor tuning ability, etc., to improve the control ability and the possibility of vibration , the effect of improving dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

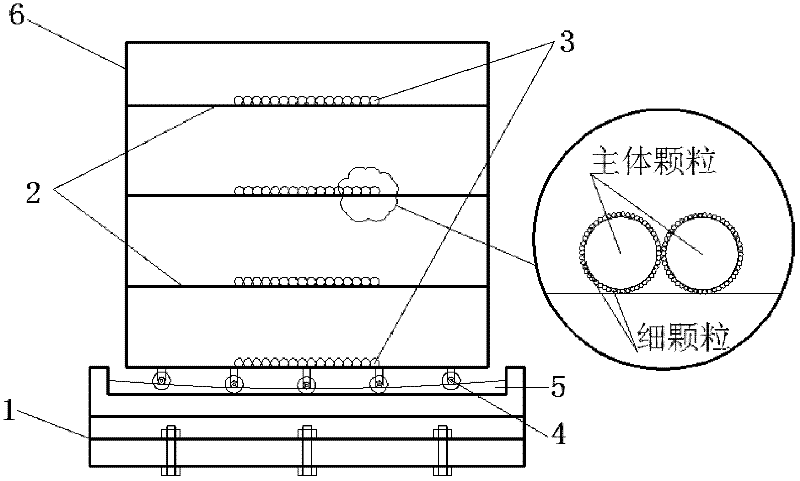

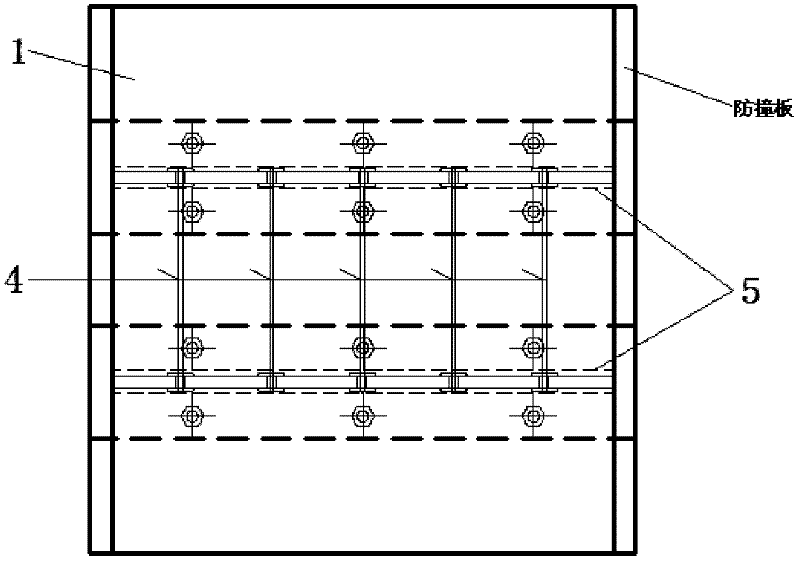

[0023] Such as Figure 1 to Figure 4 As shown, it is a sliding compartment type multi-stage distribution energy-tuning particle damper of the present invention, which mainly includes a damper anchoring device 1, a damper compartment plate 2, a multi-stage distribution damping particle group 3, and a directional sliding Support 4, slide groove 5 and damper cavity 6.

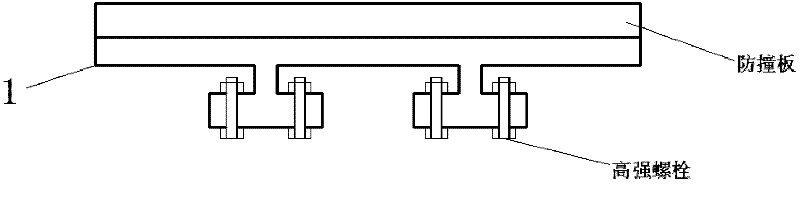

[0024] The damper anchoring device 1 is an I-shaped steel, which is connected to the anchor plate reserved by the structural member through high-strength bolts or directly embedded in the concrete with the high-strength bolts and then connected to the damper anchoring device. 5. The layout direction should be adjusted for the main direction layout of the first-order formation of the structure. The damper compartment plate 2 is a 5 mm smooth steel plate, which is connected to the damper cavity 6 by welding, and connected to the damper anchoring device 1 through the directional sliding support 4 . The one-way slid...

Embodiment 2

[0035] Such as Figure 1 to Figure 4 As shown, it is a sliding compartment type multi-stage distribution energy-tuning particle damper of the present invention, which mainly includes a damper anchoring device 1, a damper compartment plate 2, a multi-stage distribution damping particle group 3, and a directional sliding Support 4, slide groove 5 and damper cavity 6.

[0036]The damper anchoring device 1 is an I-shaped steel, which is connected to the steel plate reserved for the structure by welding. The damper anchoring device 1 is generally adjusted according to the arrangement direction of the sliding groove should be the main direction of the first-order formation of the structure. The damper bulkhead 2 is treated with 3mm inner surface bonded fine sand or bonded sandpaper. The damper compartment plate is connected with the damper cavity 6 by bolts to form a compartment. The damper cavity 6 is connected with the damper anchoring device 1 through the directional sliding su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com