Square covering square hollow sandwiched carbon fiber steel rib-steel pipe concrete combined column

A technology of steel pipe concrete and carbon fiber, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient utilization of core concrete and waste of materials, and achieve the effects of avoiding indoor energy loss, reducing construction difficulty, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

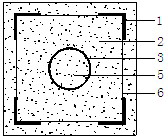

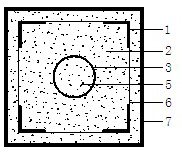

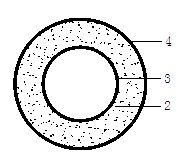

[0033] The square sleeve square hollow carbon fiber steel frame-concrete steel tube column component is mainly composed of core steel pipe (square) 3, interlayer concrete 2, angle steel 1, decorative plate 8 and carbon fiber cloth 7. Section form as attached Figure 4 shown. The steel pipe and the angle steel can be pre-welded with steel bars to fix the relative position, and the angle steel is welded with a patch plate. Figure 5 shown. The exterior of the angle steel needs to reserve a concrete protective layer according to the structural requirements, and the flatness of the concrete protective layer must be ensured during construction so that the carbon fiber cloth can be bonded externally. The schematic diagram of the test piece is attached Figure 6 shown.

[0034] In the present invention, the outer steel framework is composed of angle steel 1 with four cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com