Flow meter of perforated plate

A technology of perforated plates and flow meters, which is applied to the volume/mass flow generated by mechanical effects, and the direction of fluid flow detection by measuring pressure difference, can solve the problems of flow field disorder, complex device structure, and reduced flow efficiency, and achieve fluid flow. Uniform field distribution, convenient installation and use, and the effect of reducing supporting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

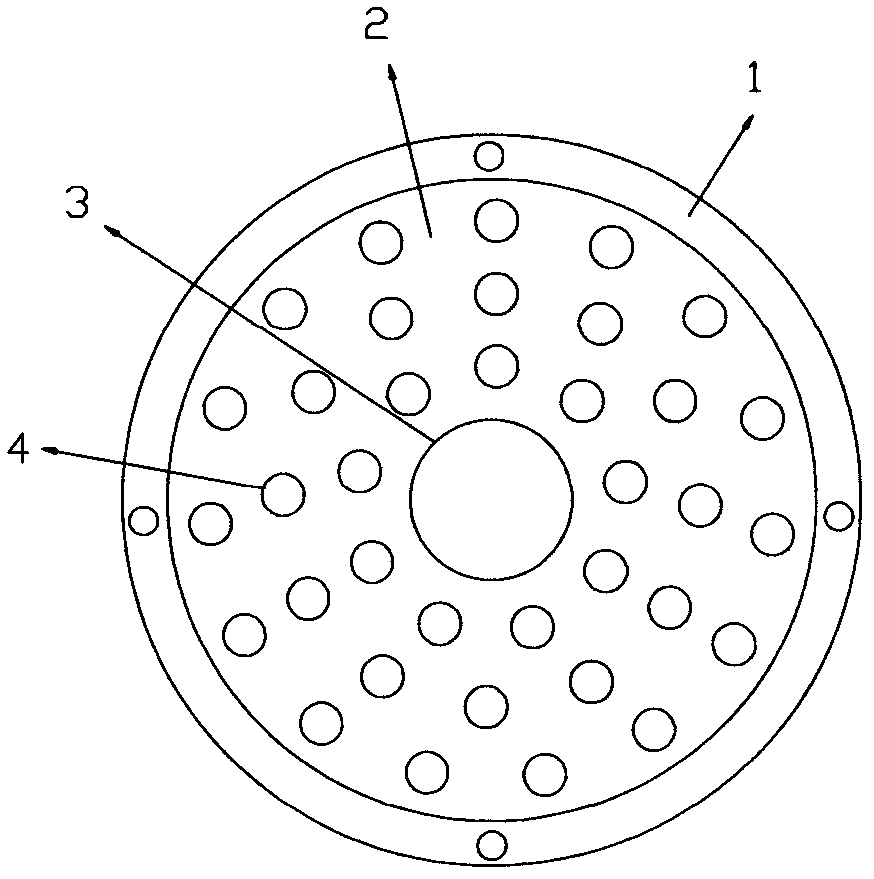

[0028] As attached figure 1 , Attached Figure 4 As shown, the diameter of the circular plate substrate 2 is equal to the diameter of the pipe 6, and the opening rate of the holes on the substrate 2 is 20%; the substrate 2 is type ①: the center of the substrate 2 has a large circle Holes 3 and other parts of the substrate 2 are evenly arranged with several small round holes 4, the diameter of the small round holes 4 is 2 mm, and the diameter of the large round hole 3 is 3 times the diameter of the small round hole 4. The flowmeter is the first type: direct-reading inclined tube differential pressure flowmeter 8. The flange sheet 1 of the perforated plate is fixedly connected in the pipeline 6 through the pipeline flange.

Embodiment 2

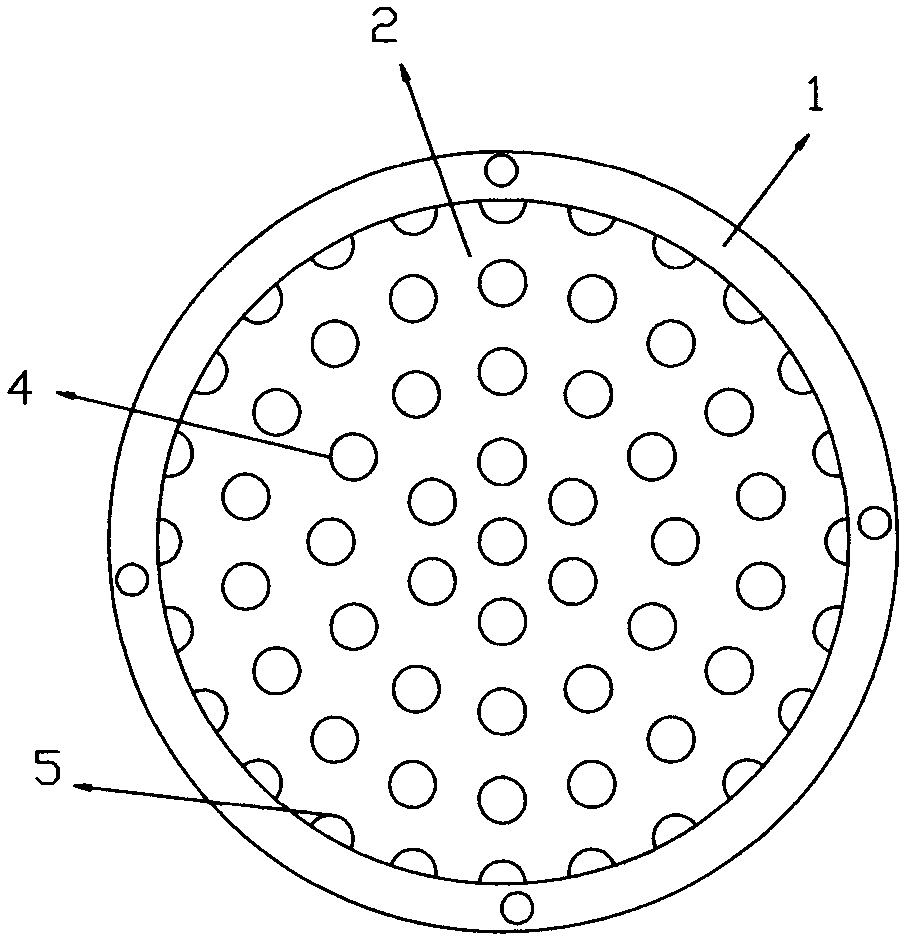

[0030] As attached figure 2 , Attached Figure 5 As shown, the diameter of the substrate 2 is equal to the diameter of the pipe 6, and the opening rate of the holes on the substrate 2 is 30%; the substrate 2 is the second type: the substrate 2 is evenly arranged with several pieces of the same diameter Small round hole 4, the diameter of the small round hole 4 is 3mm, but the outermost small round hole 4 intersects the periphery of the base plate 2 and appears as a non-circular hole 5; the flow meter is the second type: the differential pressure sensor 9 and The secondary meter 10 is connected together with an indirect reading flow meter. The perforated plate is fixedly connected in the pipeline 6 through a sleeve. When the perforated plate is installed in the pipe 6, the center of a non-circular hole 5 is directly below the center of the pipe.

Embodiment 3

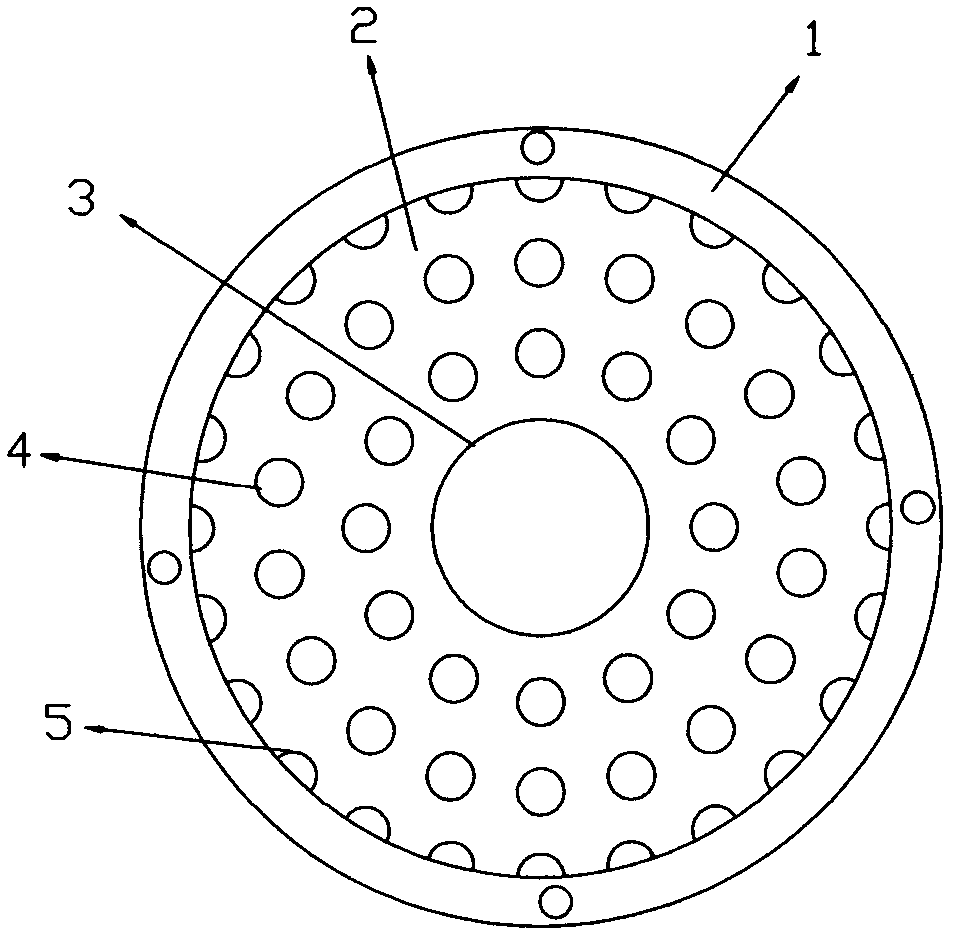

[0032] As attached image 3 , Attached Image 6 As shown, the diameter of the circular substrate 2 of the perforated plate is slightly larger than the diameter of the pipe 6, and its error is smaller than the diameter of the small circular hole 4; the opening rate of the holes on the substrate 2 is 45%; the substrate 2 is the third Variety, the center of the substrate 2 has a large circular hole 3, and other parts of the substrate 2 are evenly arranged with several small circular holes 4, the diameter of the small circular holes 4 is 4mm, but the outermost small circular hole 4 intersects the periphery of the substrate 2 It appears as a non-circular hole 5, the diameter of the large round hole 3 is 5 times the diameter of the small round hole 4; the flow meter is the third type: the differential pressure switch 11, the differential pressure sensor 9 and the secondary instrument connection 10 are connected together Indirect reading flowmeter. The perforated plate is fixedly con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com