Apparatus for detecting precision of pressure scan system sensor in real time

A pressure sensor and sensor technology, applied in measurement devices, measuring fluid pressure, instruments, etc., can solve the problems of inability to real-time verification of pressure scanning system sensor acquisition accuracy and quality deterioration, etc., to achieve strong practicability, simple methods, and improved The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

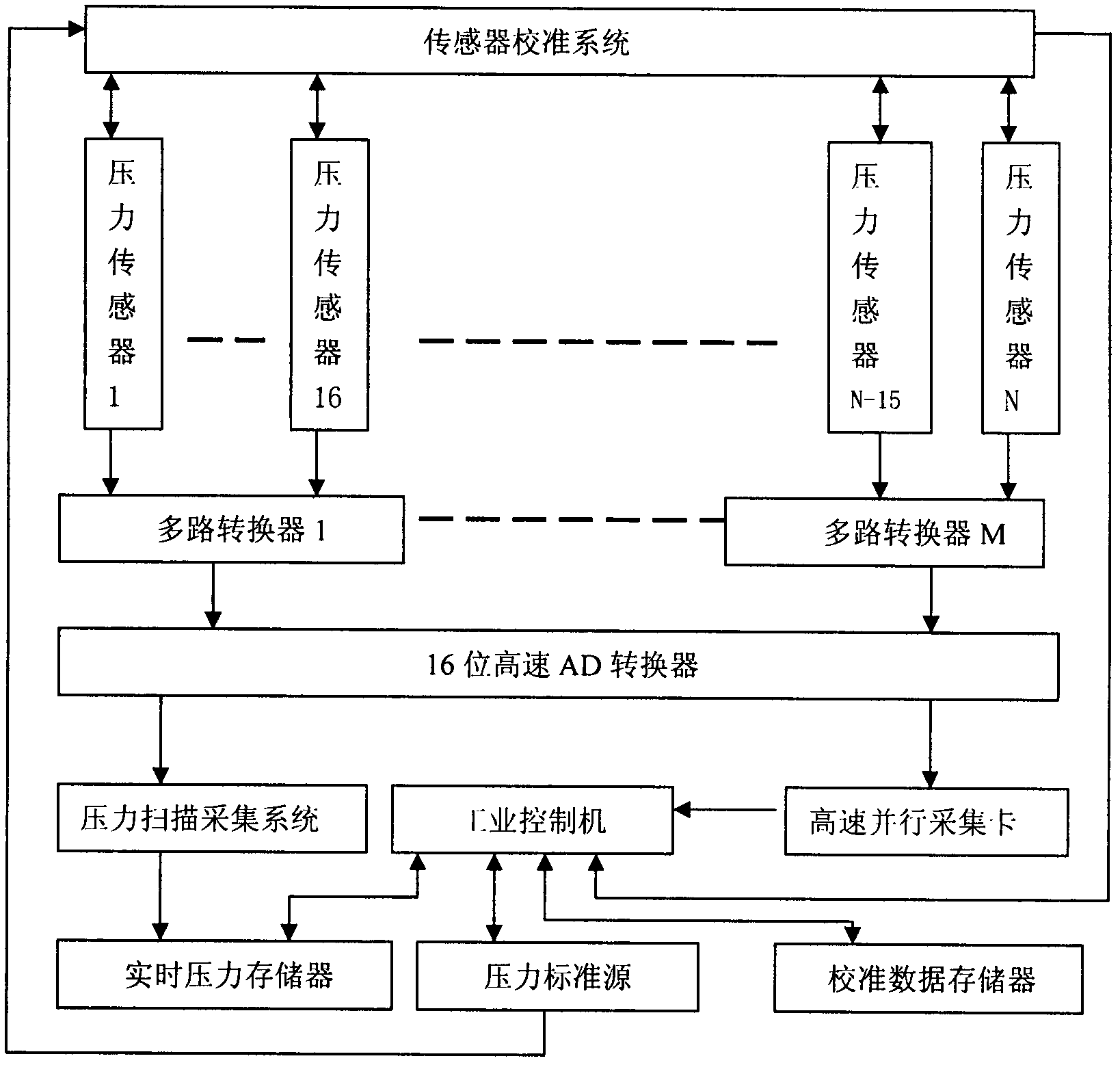

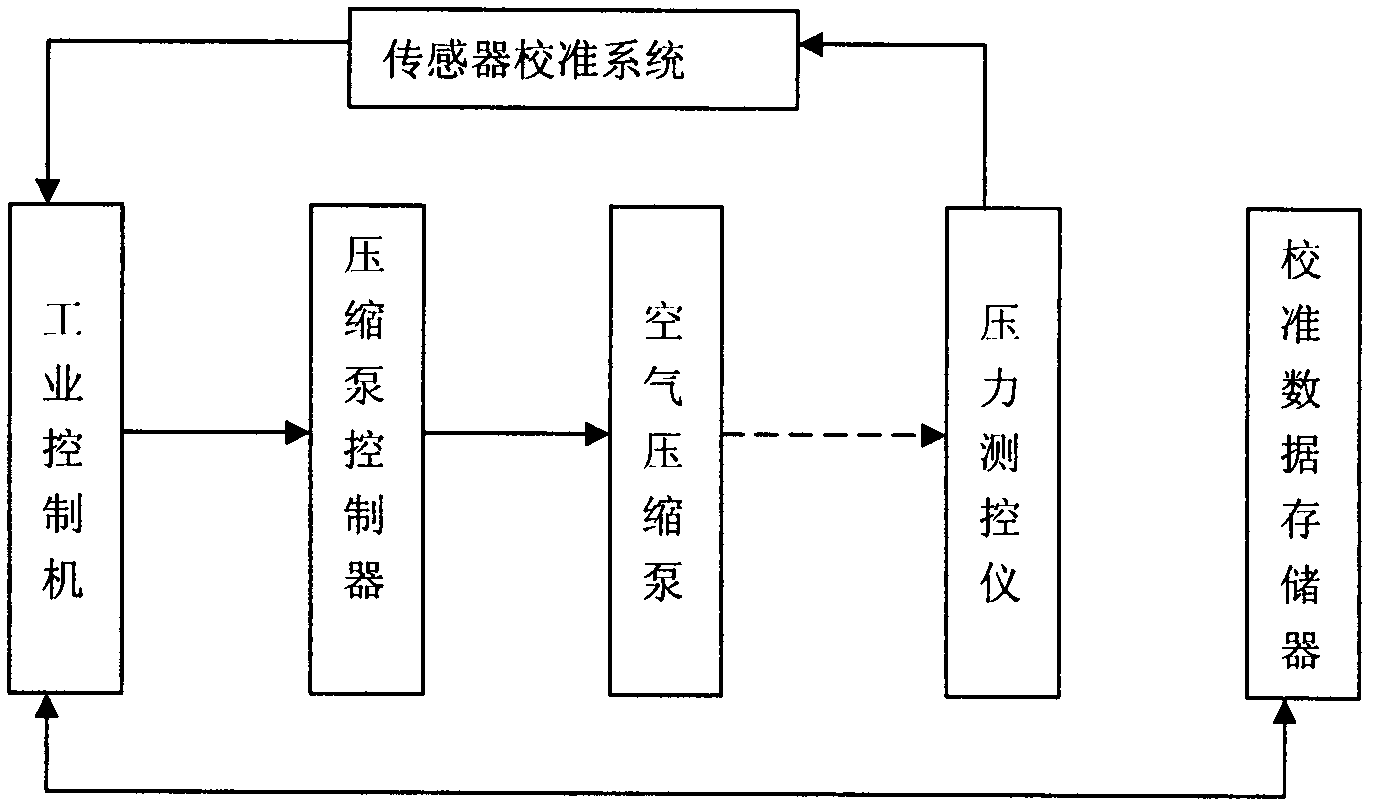

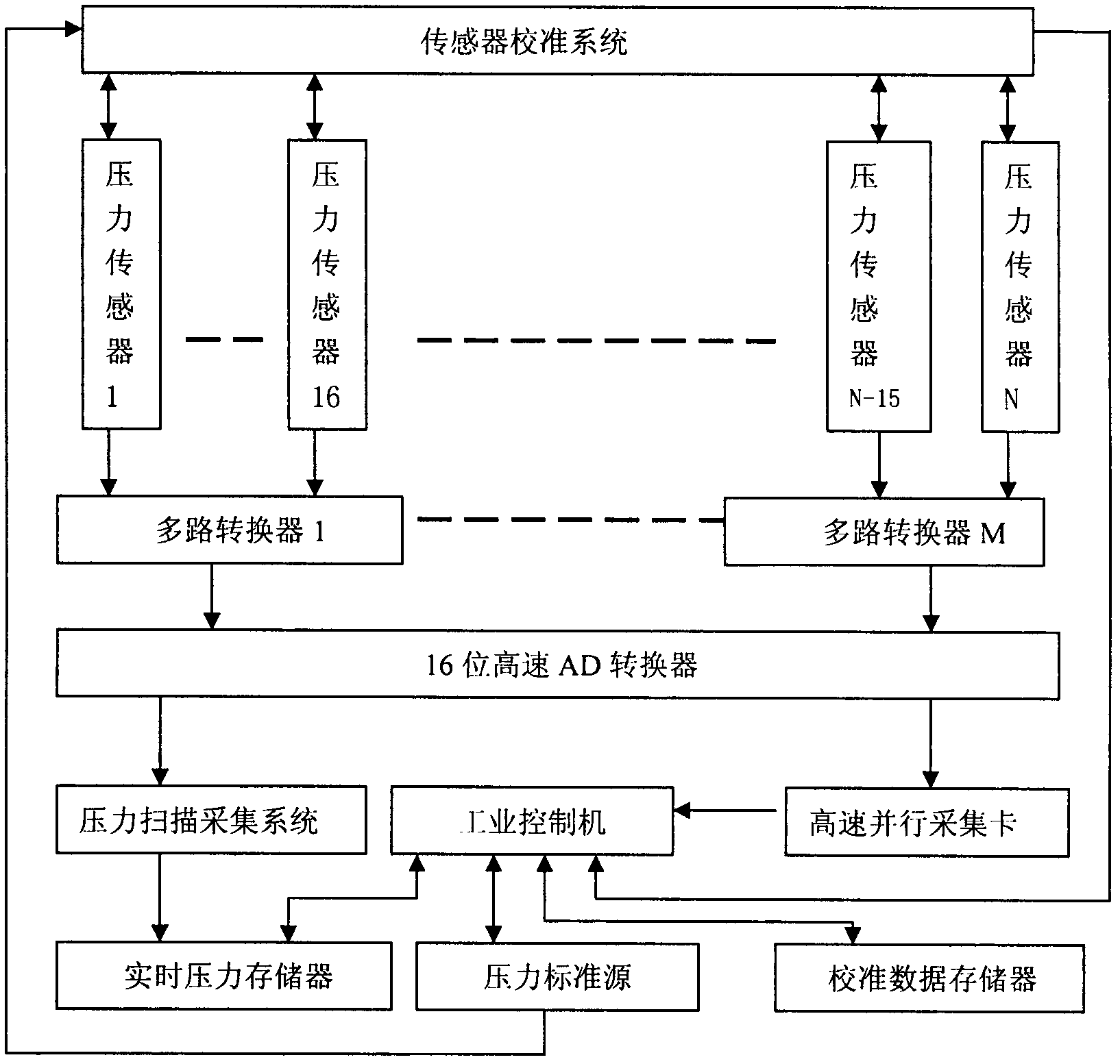

[0011] figure 1 It is a schematic diagram of the device of the present invention, and N=608, M=38, and G=10 are selected. Using 608 pressure sensors with model PSI9816 to collect the output of 10 sets of pressure from the sensor calibration system model is JCX-1 to 38 multiplexers with model ADG731, 10 sets of analog pressure data are obtained, through the 16-bit model of AD9238 High-speed AD converter converts 10 groups of digital signal pressure data P 数字信号608 , 10 groups of real-time pressure data P are obtained by serial scanning of the pressure scanning acquisition system model PSI9816-98RK in chronological order 实时N , and stored in the real-time pressure memory model K9WBG08U1M, and the high-speed parallel acquisition card model EM-9135 collects 10 sets of digital signal pressure data P in parallel 数字信号608 , get parallel data P 并行608 , transmitted to the industrial control computer with model IPC610, the industrial control computer will parallel data P 并行608 It is tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com