Sectional collecting device of surface flow silt sample

A technology of collecting device and surface runoff, applied in the direction of sampling device, etc., can solve the problem of failure to observe the sediment transport process, and achieve the effect of realizing the process observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

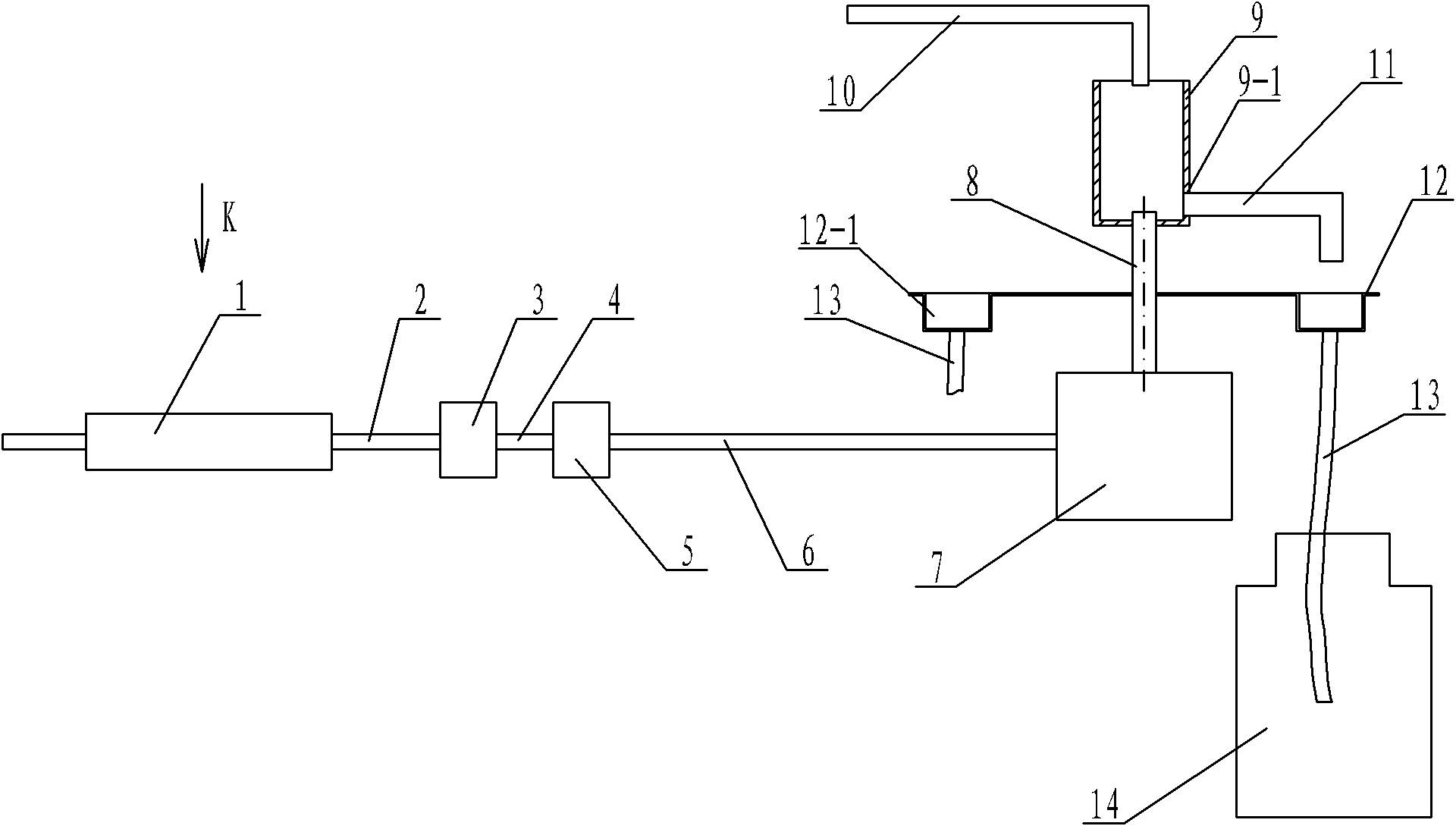

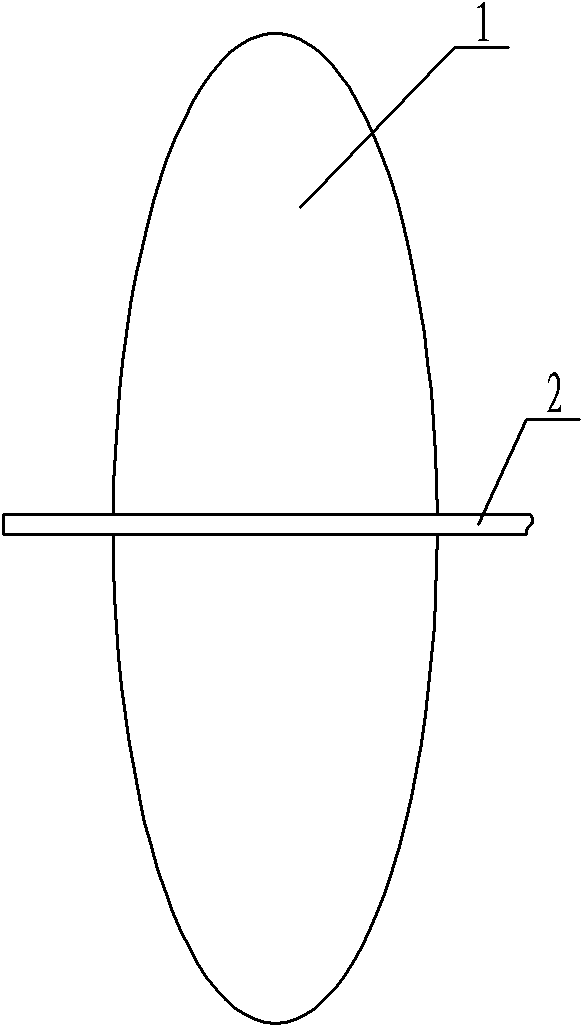

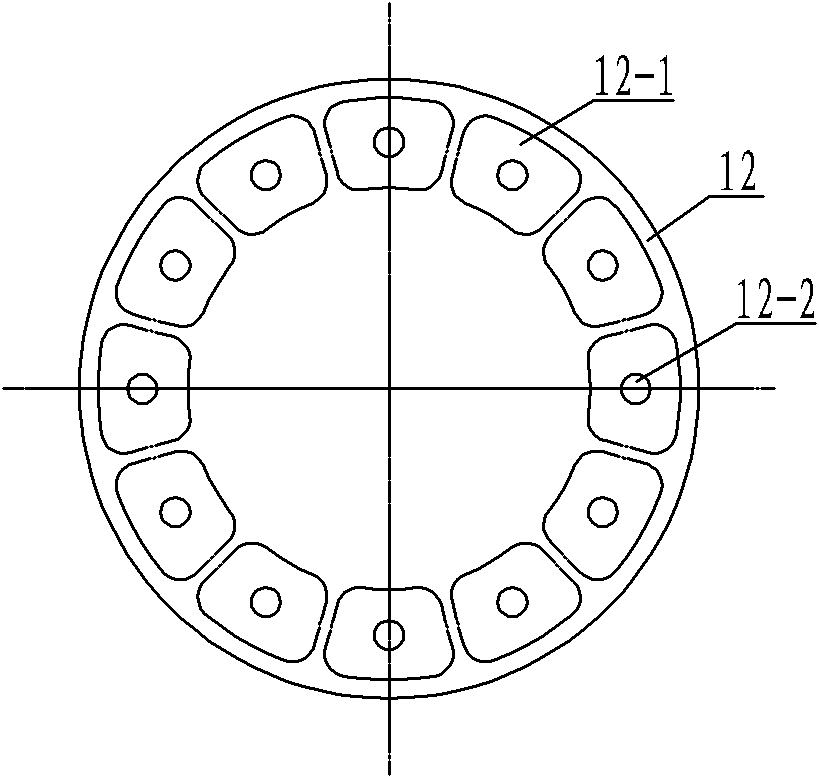

[0011] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes bucket 1, main transmission shaft 2, first overrunning clutch 3, first slave transmission shaft 4, second overrunning clutch 5, second slave transmission shaft 6, worm gear reducer 7, The third slave transmission shaft 8, nylon bucket collector 9, shunt overflow pipe 10, outflow elbow 11, stainless steel water diversion pan 12, twelve plastic pipes 13 and twelve plastic sample collection bottles 14, the tipping bucket 1 Fixed on the main transmission shaft 2, the output end of the main transmission shaft 2 is connected with the input end of the first slave transmission shaft 4 through the first overrunning clutch 3, and the output end of the first slave transmission shaft 4 is connected with the input end of the first slave transmission shaft 4 through the second overrunning clutch 5. The second is connected from the input end of transmission shaft 6, the ou...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 The present embodiment will be described. The inner diameter of the nylon barrel collector 9 of the present embodiment is 40 mm to 50 mm, and the height is 45 mm to 50 mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 The present embodiment will be described. The inner diameter of the nylon barrel collector 9 of the present embodiment is 45 mm and the height is 50 mm. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com