Testing method and testing probe platform for image sensor chip

A technology of image sensor and test method, applied in the parts, instruments, measuring electricity and other directions of electrical measuring instruments, can solve the problems of decreased yield rate, poor positioning accuracy, long auxiliary time of pick and place action, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below through embodiments in conjunction with the accompanying drawings.

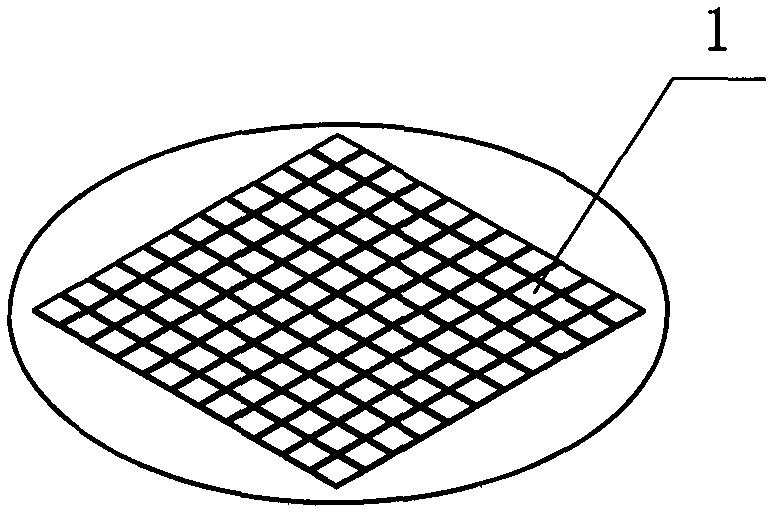

[0027] The test method for testing the image sensor chip is that the chip of the image sensor to be tested is composed of a plurality of chips 1 to form a wafer 2 such as figure 1 carried out in the state shown. It is tested under the condition that the chip 1 of the image sensor under test is packaged and still in the state of the wafer 2 after the electrical performance test.

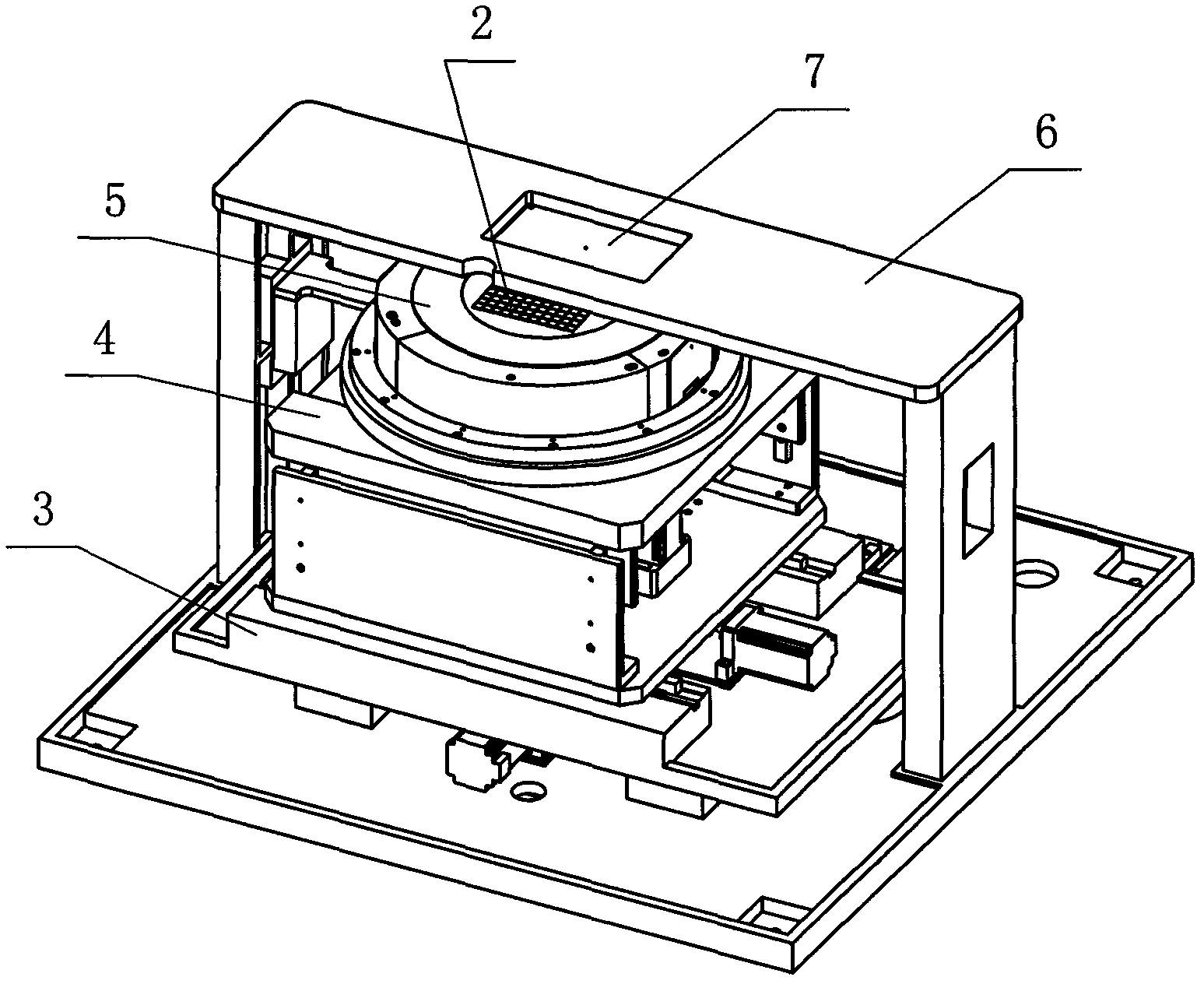

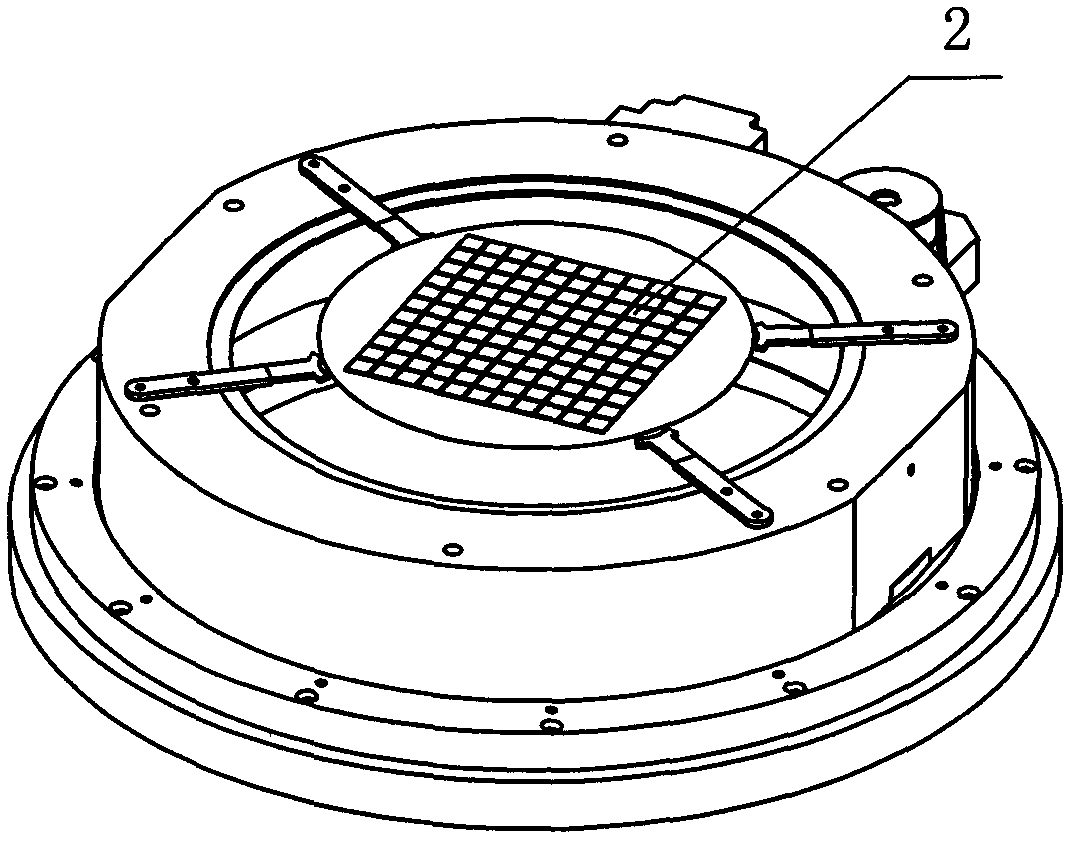

[0028] Utilize the probe station designed by the testing method of above-mentioned testing image sensor chip as figure 2 , 3 , 4, including an XY platform 3 that can move back and forth, left and right, and an elevating platform 4 that can move up and down is installed on the XY platform 3, and the elevating platform 4 is equipped with a wafer 2 for placing and can be used for circumferential rotation The chip carrier 5 is provided with a support frame 6 above the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com