Anisotropic nano-crystalline composite permanent magnetic material and preparation method thereof

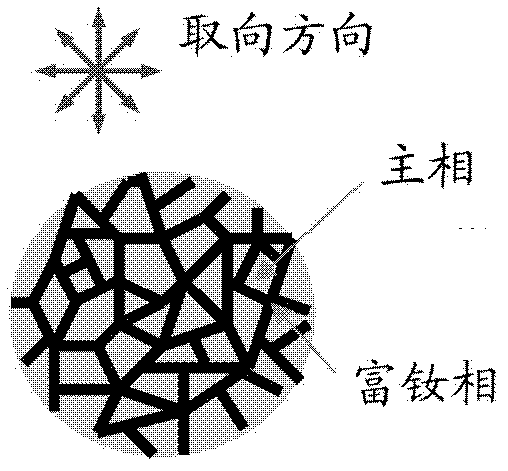

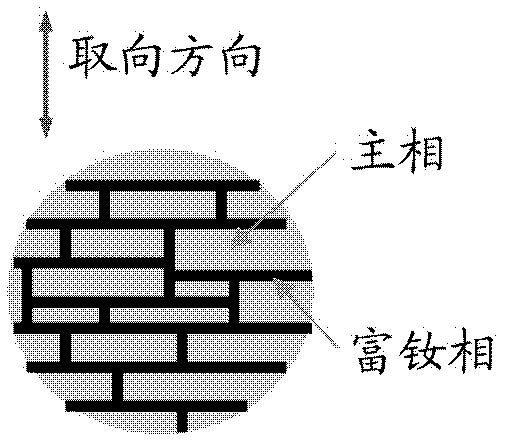

A nanocrystalline composite and anisotropic technology, applied in the field of material manufacturing, can solve the problems of difficulty in preparing bulk anisotropic nanocrystalline composite permanent magnet materials, poor orientation of isotropic magnets, etc., and achieve good chemical stability, Effects of low rare earth content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

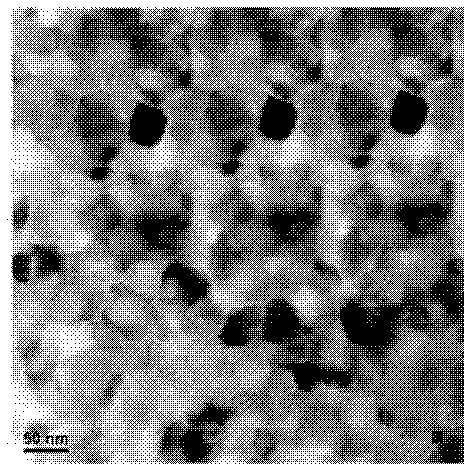

Method used

Image

Examples

Embodiment 1

[0037] This example is prepared from samples under laboratory conditions.

[0038] 1) The composition obtained by smelting and refining is: Nd 13.6 Fe 77.6 co 2.6 Ga 0.5 Cu 0.1 B 5.6 The Nd-Fe-B alloy ingot is prepared into a nanocrystalline magnetic powder sample by rapid quenching under an argon protective atmosphere, so that the nanocrystalline magnetic powder sample has an excellent permanent coercive force greater than 13000Oe Magnetic properties.

[0039] 2) Put the above-mentioned nanocrystalline magnetic powder sample with excellent permanent magnetic properties into a mold for hot pressing process; use induction heating to rapidly heat the mold and sample to 600°C, and then apply pressure to the sample to make the sample reach a full density of about 7.6g / cm 3 The same-sex magnet sample, then stop heating and pressurization, the sample is controlled within 5 minutes in the high temperature stage, the whole hot pressing process is completed under high vacuum, an...

Embodiment 2

[0047] This embodiment is the preparation process of the product in actual production.

[0048] 1) The composition obtained through smelting and refining is: Nd 12.2 PR 1.5 Fe 76.6 co 3.6 Ga 0.4 Cu 0.2 B 5.6 The Nd-Fe-B alloy ingot is prepared into nanocrystalline magnetic powder by rapid quenching under the protective atmosphere of argon. The coercive force of the nanocrystalline magnetic powder is detected to be 16000Oe, which has the required permanent magnetic properties.

[0049] 2) Put the above-mentioned nanocrystalline magnetic powder into a mold for hot pressing; use the current heating method to heat the mold and magnetic powder to 800°C quickly, and then apply pressure to the magnetic powder to make the magnetic powder reach a full density of about 7.6g / cm 3 Same-sex magnets, then stop heating and pressurization. During the production process, the magnetic powder is controlled within 5 minutes at the high temperature stage. The entire hot-pressing process is c...

Embodiment 3

[0057] This embodiment is the preparation process of the product in actual production.

[0058] 1) The composition obtained through smelting and refining is: Nd 10.6 Dy 3 Fe 73.6 co 6.6 Ga 0.6 B 5.6 The Nd-Fe-B alloy ingot is prepared into nanocrystalline magnetic powder by rapid quenching under the protective atmosphere of argon. The coercive force of the nanocrystalline magnetic powder is 25000Oe, which has the required permanent magnetic properties.

[0059] 2) Put the above-mentioned nanocrystalline magnetic powder into a mold for hot pressing; use the current heating method to heat the mold and magnetic powder to 700°C quickly, and then apply pressure to the magnetic powder to make the magnetic powder reach a full density of about 7.7g / cm 3 Same-sex magnets, then stop heating and pressurization. During the production process, the magnetic powder is controlled within 5 minutes at the high temperature stage. The entire hot-pressing process is completed under high vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com