Polysilicon alkaline wool making method

A technology of polycrystalline silicon and polycrystalline silicon wafers, applied in the field of solar cells, can solve the problems of high cost and low price, and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

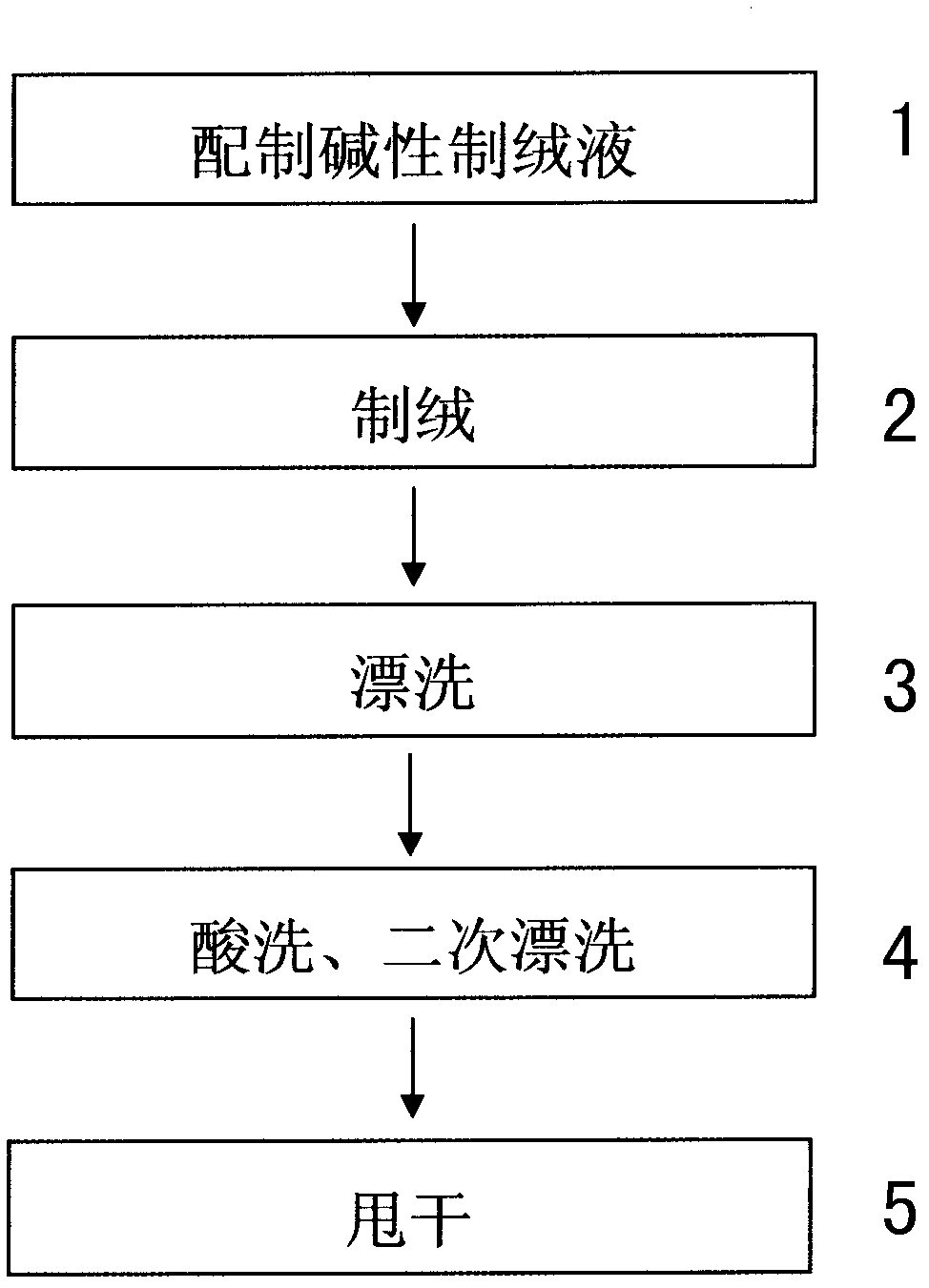

[0032] Example 1 Alkaline Texturing System NaClO 3 -The preparation method of NaOH.

[0033] The alkaline texturing solution is prepared from analytically pure powder chemical reagents and deionized water, and the operation is carried out on a laboratory bench with a fume hood. Use an electronic balance to weigh the analytically pure NaClO 3 180 grams of powder, 25 grams of NaOH powder, put the two chemical reagents in a polytetrafluoroethylene tank with a volume of 2.5L, add deionized water to the 2L water level, and use a glass rod to stir evenly.

Embodiment 2

[0034] Embodiment 2 adopts alkaline texturing system NaClO 3 -The specific implementation steps of NaOH texturing.

[0035] Prepare the texturing liquid in a 2.5L polytetrafluoroethylene tank, place the polytetrafluoroethylene tank in a constant temperature water bath, set the temperature of the water bath at 85°C, and keep the texturing liquid at 80°C ± 5°C.

[0036] Take a piece of polycrystalline silicon wafer with a size of 156mm×156mm, clamp the polycrystalline silicon wafer with tweezers, soak it in the texturing solution in the polytetrafluoroethylene tank, and perform texturing for 55-60 seconds. There are two main functions in the texturing process, one is to remove oil stains and wire saw damage layers, and the other is to form a light-trapped suede surface. The related chemical reactions are shown in the following reaction formula.

[0037] After the texturing is completed, place the polysilicon wafer in a rinsing tank filled with deionized water for 120 seconds of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com