Production method for squashed patch plastic package diode based on axial diode production line

An axial diode and production method technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of wasting time and increasing costs, and achieve the goal of reducing production costs, meeting social needs, and saving money and time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

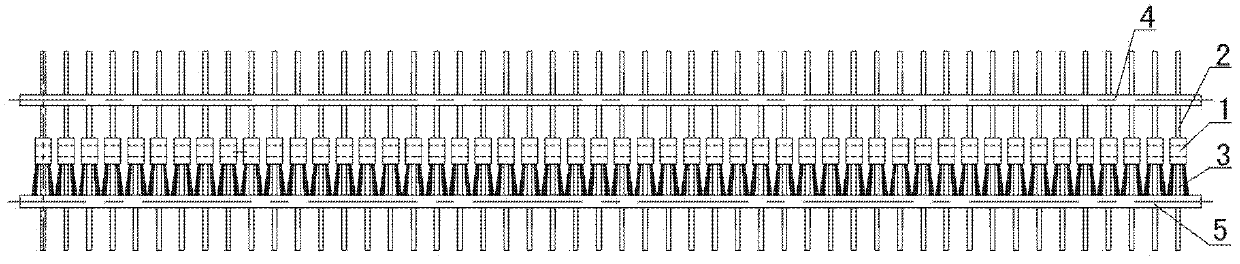

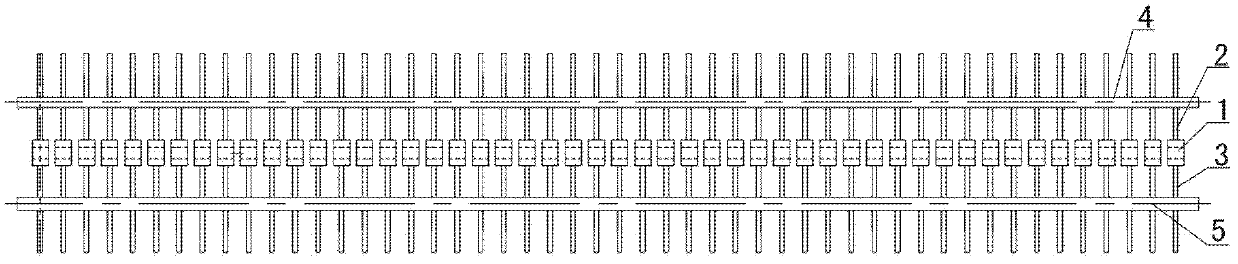

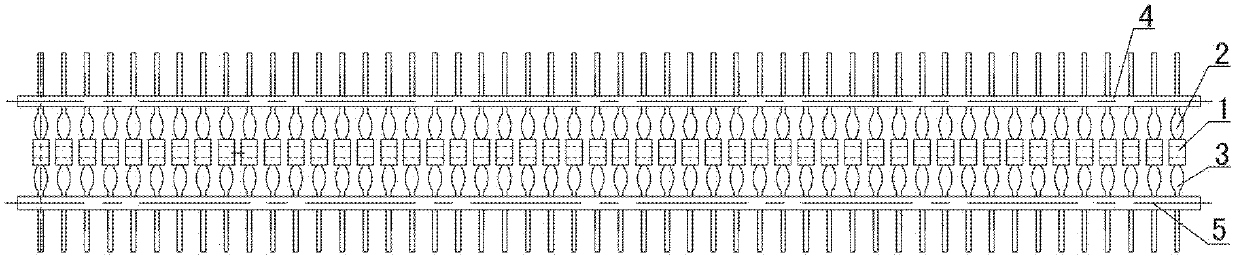

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] The invention includes the following processes: chip testing→assembly with lead frame→sintering→pickling→gluing→baking→plastic sealing→post-curing→waste removal→flattening→rib cutting and forming→electroplating→printing test→external inspection→packaging→ QA inspection→warehousing. In the process, the chip testing, assembly with lead frame, sintering, pickling, gluing, baking, post-curing, electroplating, printing test, external inspection, packaging, QA inspection and storage are carried out on the axial diode production line Complete, the plastic sealing is completed on the plastic sealing mold, the waste removal is completed on the waste removal mold, the flattening is completed on the flattening mold, and the rib cutting and forming is completed on the rib cutting forming mold.

[0018] As can be seen from the above, the focus of the present invention is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com