Ball screw sliding table high-speed precision synchronous punching and shearing device

A ball screw and desktop technology, applied in the field of profile processing, can solve the problems of backward technology and industrial equipment, not in line with social development, low work efficiency, etc., and achieve the effect of improving safety production guarantee, small size and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

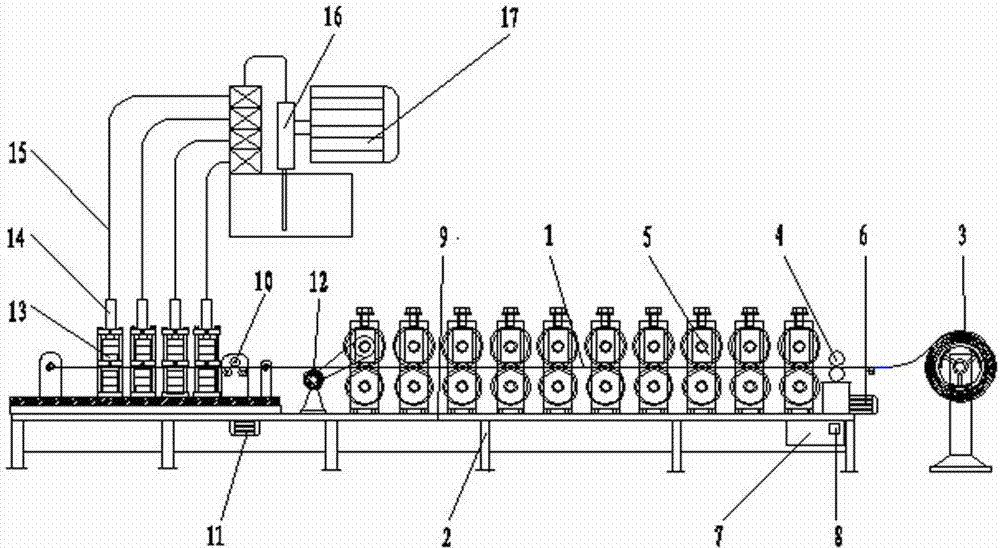

[0010] see figure 1 , a ball screw sliding table type high-speed precision synchronous punching and shearing profile cutting machine, including an intelligent console and a working assembly line 1, the working assembly line 1 is set up on a frame 2, and the end of the assembly line 1 is provided with a feeder 3, and the feeder 3 Send the material to the roller 4 at the front end, and the roller 4 will straighten the material. There are several rolling machines 5 at the front end of the roller 4. The rolling machine 5 is driven by the motor 6 on one side. The rolling machine 5 is in the process of transporting the material. The material is molded in the middle, and a water tank 7 is provided under the motor 6, and the coolant in the water tank 7 is pumped into the rolling machine 5 through the water pump 8 to cool the rolling machine 5, and water tanks 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com