Method for obtaining energy distribution of section of any laser beam based on orthogonal acoustic-optic deflectors

An acousto-optic deflector, laser beam technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of quality and ability improvement, quality improvement, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method for obtaining arbitrary laser beam profile and energy according to the present invention will be further described below through specific examples.

[0015] Acquisition of laser spot with triangular shape and uniform energy distribution:

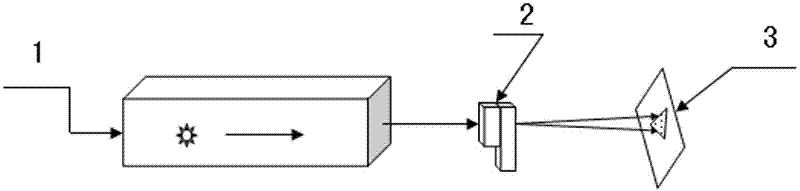

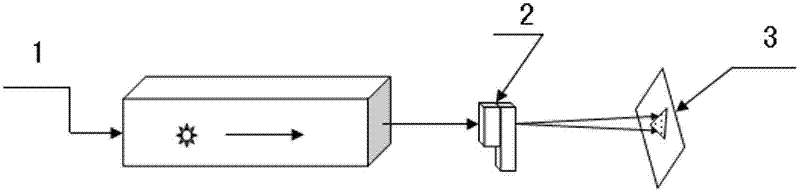

[0016] refer to figure 1 First, the orthogonal acousto-optic scanning deflector 2 is placed orthogonally at the output port of the laser 1 . Set the target laser spot area to 0.2mm 2 of triangular spots. Adjust the excitation waveform of the X, Y direction acousto-optic deflector (the required waveform is generated by an external waveform generator) and the power of the laser beam to 15W, so that the laser beam can be scanned at a small angle and high frequency, and the cross-sectional area can be obtained as 0.2mm 2 , a triangular equivalent laser spot with a power of 15W and a uniform distribution of power. The obtained equivalent laser spot can be used to process the etched section into a V-shaped groove structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com