Method for simultaneously extracting polysaccharides and saponins from astragalus

A technology of astragalus and polysaccharide, applied in the field of medicine, can solve problems such as waste of traditional Chinese medicine resources, and achieve the effects of saving resources, shortening production cycle, and overcoming single product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

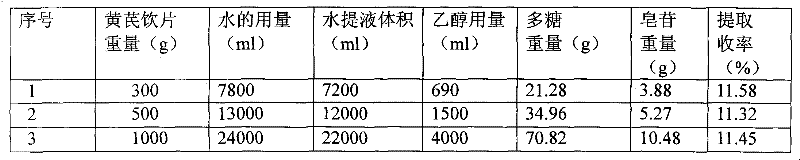

Embodiment 1

[0012] Take 300g of astragalus decoction pieces, put them in a reflux extraction tank, add distilled water to decoct 4 times, decoct with 12 times the amount of water (soaked for 0.5h) for 2 hours for the first time, decoct for 1.5 hours with 8 times the amount of water for the second time, and decoct for 1.5 hours with 8 times the amount of water for the second time Decoct with 6 times the amount of water for 1 hour for the third time, and decoct for 1 hour with 6 times the amount of water for the fourth time, combine the decoction liquid, filter, concentrate the filtrate to 1 g of the original medicinal material per ml, and precipitate with ethanol to make the The alcohol content reaches 70%, refrigerate overnight at 4°C, filter, take the precipitate I and the filtrate I separately, and set aside, the precipitate I is repeatedly washed with ethanol, and dried under reduced pressure at 30-40°C to obtain the extract of astragalus polysaccharide; the filtrate I is recovered Conc...

Embodiment 2

[0014] Take 500g of astragalus decoction pieces, put them in a reflux extraction tank, add distilled water to decoct 3 times, decoct for 2 hours with 10 times the amount of water (soaked for 1 hour) for the first time, decoct for 1.5 hours with 8 times the amount of water for the second time, and decoct for 1.5 hours with 8 times the amount of water for the third time. Decoct with 8 times the amount of water for 1 hour each time, combine the decoction liquid, filter, concentrate the filtrate to 1 g of the original medicinal material per ml, precipitate with ethanol to make the alcohol content reach 75%, refrigerate overnight at 4°C, filter, respectively Take the two parts of the precipitate I and the filtrate I, set aside, wash the precipitate I repeatedly with ethanol, and dry it under reduced pressure at 30-40°C to obtain the extract of astragalus polysaccharide; recover the ethanol from the filtrate I and concentrate it to the equivalent of 10g of the original medicinal mater...

Embodiment 3

[0016] Take 1000g of astragalus decoction pieces, put them in a reflux extraction tank, add distilled water to decoct 3 times, decoct with 10 times the amount of water (soaked for 2 hours) for 2 hours for the first time, decoct for 2 hours with 8 times the amount of water for the second time, and decoct for 2 hours with 8 times the amount of water for the third time Decoct with 6 times the amount of water for 1 hour each time, combine the decoction liquid, filter, concentrate the filtrate to 1 g of the original medicinal material per ml, precipitate with ethanol to make the alcohol content reach 80%, refrigerate overnight at 4°C, filter, respectively Take the two parts of the precipitate I and the filtrate I, set aside, wash the precipitate I repeatedly with ethanol, and dry it under reduced pressure at 30-40°C to obtain the extract of astragalus polysaccharide; recover the ethanol from the filtrate I and concentrate it to the equivalent of 10g of the original medicinal material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com