Method for selectively growing nickel

A selective, seed layer technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of difficult selective nickel plating, organic contamination and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

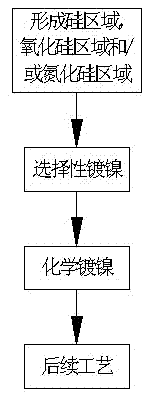

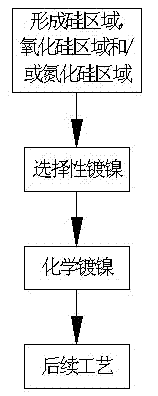

[0026] figure 1 It is a schematic flow sheet of a method for selectively growing nickel of the present invention; as figure 1 Shown, a kind of method of selective growth nickel of the present invention:

[0027] First, a silicon region consisting of a gate region and a source-drain region is prepared on a wafer, and a silicon oxide region and / or a silicon nitride region is prepared at the same time; wherein, at least one of the silicon oxide region and the silicon nitride region contains One; wherein the silicon oxide region includes sidewalls and shallow trench regions.

[0028] Then, immerse the wafer in a certain concentration of dilute hydrofluoric acid solution containing nickel ions to perform selective nickel plating to form a nickel seed layer on the silicon region; When in the solution for 5s to 600s, nickel ions will be deposited on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com