Asphalt pavement prefabricated block and construction method for prefabricated asphalt pavement

A technology of asphalt pavement and construction method, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, which can solve the problems of easy deformation and cracking during transportation and installation, difficulty in making large-sized prefabricated blocks, and shortening the service life of pavement. and other problems, to achieve the effect of being conducive to construction in the rainy season, saving materials and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The prefabricated asphalt pavement of the present invention is implemented on a certain expressway, and the pavement structure is from bottom to top: cement stabilized crushed stone base, hot asphalt bonding layer and asphalt pavement prefabricated block. The road width is 14m.

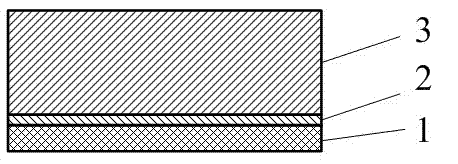

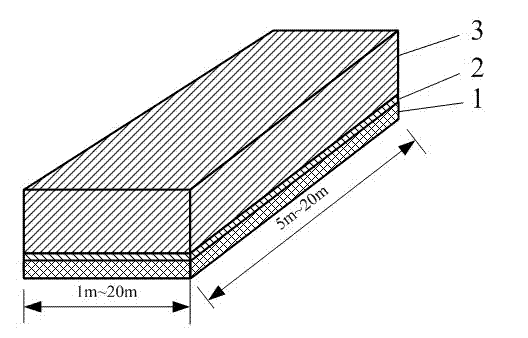

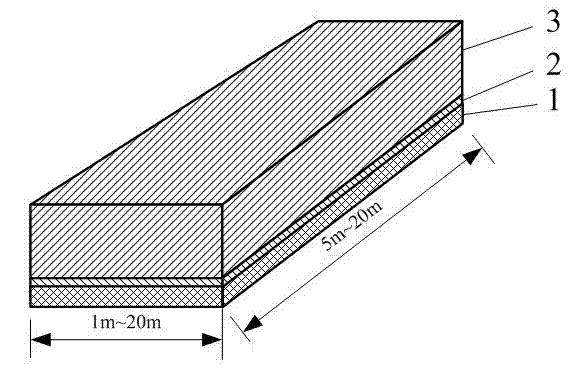

[0038] (1) Structure and size of asphalt pavement prefabricated blocks

[0039] The structure of the asphalt pavement prefabricated block is as follows from the bottom to the top: a substrate of fiber reinforced composite material with a thickness of 20 mm, an adhesive layer on the board and an asphalt surface layer. Among them, the adhesive layer on the board adopts a sprinkling amount of 2.5kg / m 2 SBS modified asphalt and 10kg / m 2 Clean limestone gravel with a particle size of 9.5~13.6mm; the asphalt surface layer is AC-20C asphalt mixture with a thickness of 6cm, and the upper layer is AC-13C asphalt mixture with a thickness of 4cm.

[0040] The plane size of the asphalt pavement prefabri...

Embodiment 2

[0054]The prefabricated asphalt pavement of the present invention is implemented on a municipal road, and the pavement structure is from bottom to top: graded crushed stone base, emulsified asphalt adhesive layer and asphalt pavement prefabricated blocks. The road width is 20m.

[0055] (1) Structure and size of asphalt pavement prefabricated blocks

[0056] The structure of the asphalt pavement prefabricated block is as follows from the bottom to the top: a substrate of fiber reinforced composite material with a thickness of 20 mm, an adhesive layer on the board and an asphalt surface layer. Among them, the adhesive layer on the board adopts a sprinkling amount of 2.5kg / m 2 SBS modified asphalt and 10kg / m 2 Clean limestone gravel with a particle size of 9.5~13.6mm; the lower layer of asphalt is 6cm thick AC-20C type asphalt mixture, and the upper layer is 4cm thick AC-13C type asphalt mixture.

[0057] The plane size of the asphalt pavement prefabricated block is: length 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com