Method for predicting multi-order temperature programming retention time according to nonlinear plate theory

A temperature-programmed, retention time technology, applied in the field of chromatography, which can solve the problems of cumbersome determination and calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

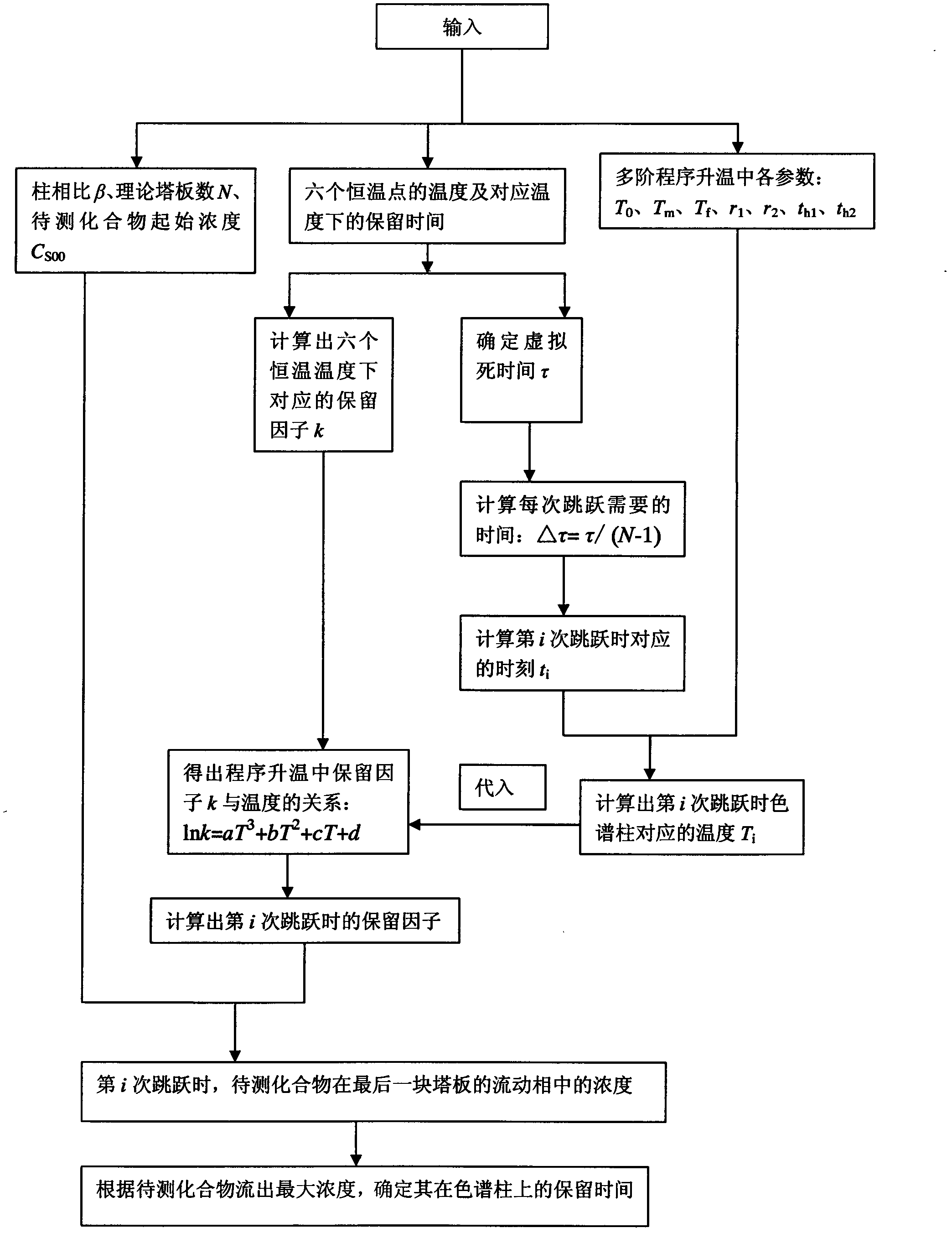

Method used

Image

Examples

Embodiment 1

[0070] Instruments: HP6890 gas chromatograph, hydrogen flame ionization detector, 6890 gas chromatograph workstation;

[0071] Chromatographic column: non-polar HP-5 (5% phenylmethylpolysiloxane) column;

[0072] Conditions: The temperature of the detector is 250°C, and the temperature of the injection port is 250°C;

[0073] Carrier gas: use high-purity nitrogen gas (purity not less than 99.999%), constant flow operation mode, that is, the carrier gas is at the outlet of the column, and the mass flow rate is kept constant at 1ml / min;

[0074] Injection method: split injection, the split ratio is 50:1, each injection volume is 0.2ul, the initial concentration C S00 = 1 μg / ml;

[0075] (1) Select isoamyl acetate as the compound to be tested, and measure its retention time at six constant temperatures of 30°C, 50°C, 100°C, 150°C, 200°C and 250°C on the HP-5 column, which are respectively 34.41min, 13.50min, 3.90min, 2.63min, 2.24min and 2.04min;

[0076] (2) Get virtual dead...

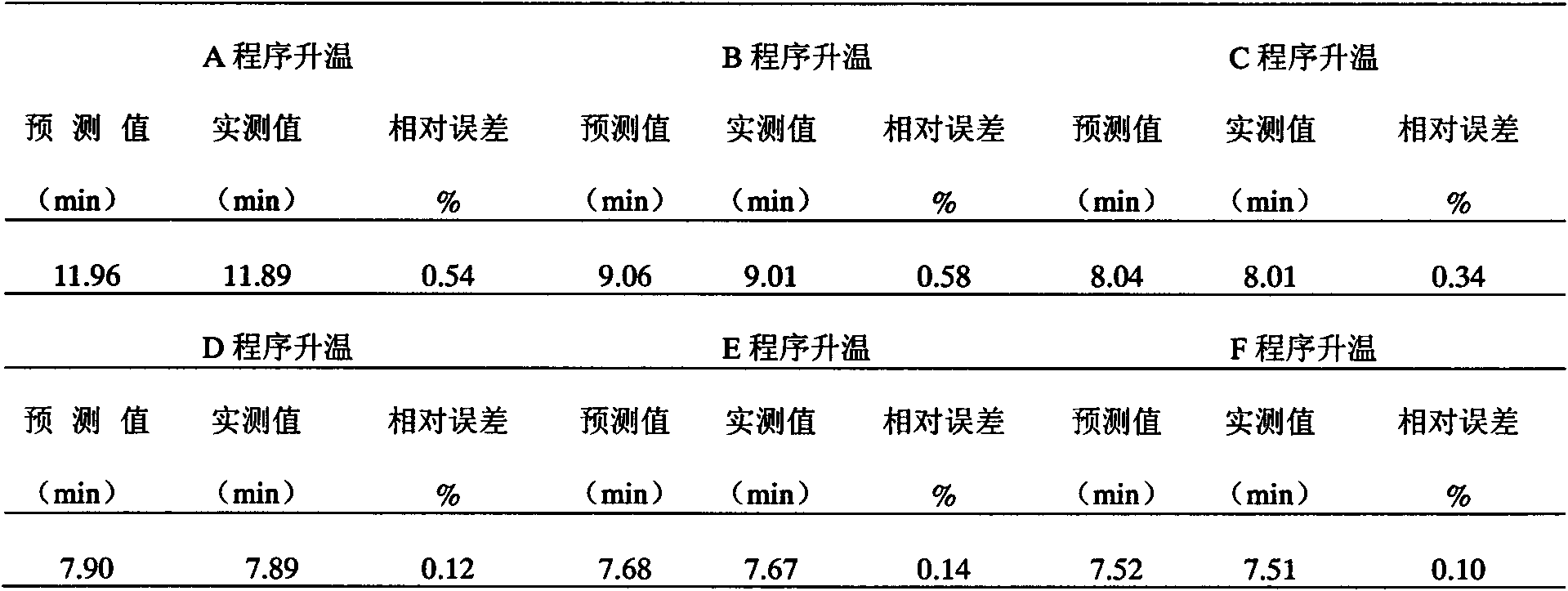

Embodiment 2

[0091] The process and condition of the present embodiment are identical with embodiment 1, and difference is:

[0092] (1) virtual dead time τ becomes 0.05min by 1.85min, calculates the retention factor of isoamyl acetate under six constant temperatures according to formula 1, they are respectively: 687.20, 269.00, 77.00, 51.60, 43.80 and 39.80; Then use Equation 2 fits the curves of the relationship between the retention factor and the temperature at six constant temperatures, and obtains the parameters a, b, c and d, which are respectively: -6×10 -7 , 0.0009, -0.4014 and 66.091; thus the relationship between the retention factor and the temperature of each compound during the temperature programming process

[0093] lnk=-6×10 -7 T 3 +0.0009T 2 -0.4014T+66.091

[0094] Choose from six different temperature programs, which are:

[0095] A program temperature rise 30°C (hold 2min) → 5°C / min → 70°C (hold 1min) → 25°C / min → 250°C;

[0096] B Program temperature rise 30°C (...

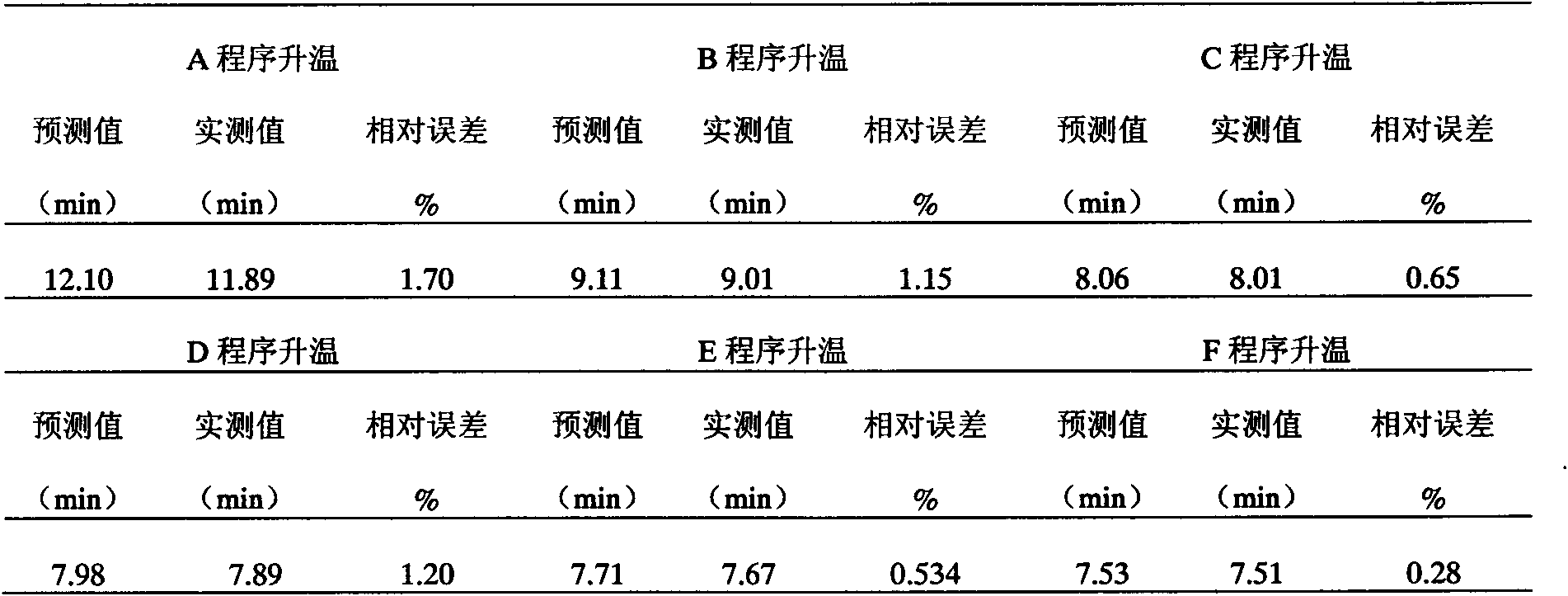

Embodiment 3

[0106] (1) Select ethanol as the compound to be tested, and measure its retention time at six constant temperatures of 30°C, 50°C, 100°C, 150°C, 200°C and 250°C on the HP-5 column, and they are 4.74min, 2.89min, 1.74min, 1.50min, 1.39min and 1.36min;

[0107] (2) Get τ=1.00min, calculate the retention factor of ethanol under six constant temperatures according to formula 1, they are respectively: 3.74, 1.89, 0.74, 0.50, 0.39 and 0.36; Then use formula 2 to the retention under six constant temperatures The curve of the relationship between the factor and the temperature is fitted to obtain the parameters a, b, c and d, which are respectively: -3×10 -7 , 0.0005, -0.2407 and 38.011; thus the relationship between the retention factor and temperature of each compound during the temperature programming process

[0108] lnk=-3×10 -7 T 3 +0.0005T 2 -0.2407T+38.011

[0109] Choose from three different temperature programs, which are:

[0110] D program temperature rise 30°C (hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com