Refrigerator equipped with vacuum insulation material

A technology of vacuum insulation materials and refrigerators, which can be used in home appliances, mechanical equipment, heat exchange equipment, etc., and can solve the problems of not being able to give full play to the thermal insulation performance, promoting the thermal bridge of the cladding material and failing to obtain the predetermined effect, etc., to achieve the purpose of suppressing thermal insulation Deterioration of performance, reduction of man-hours for assembly work, effects of uniform load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

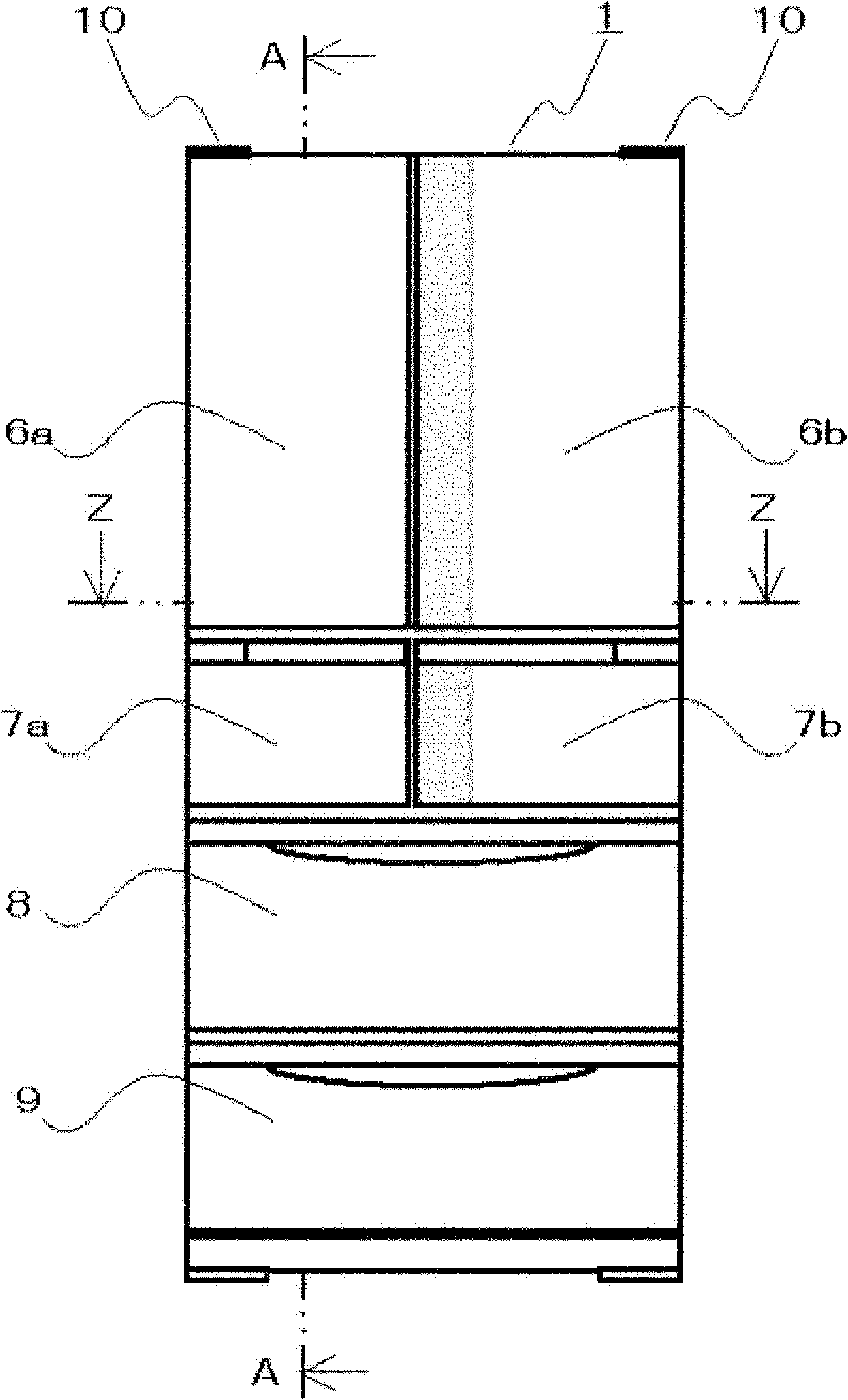

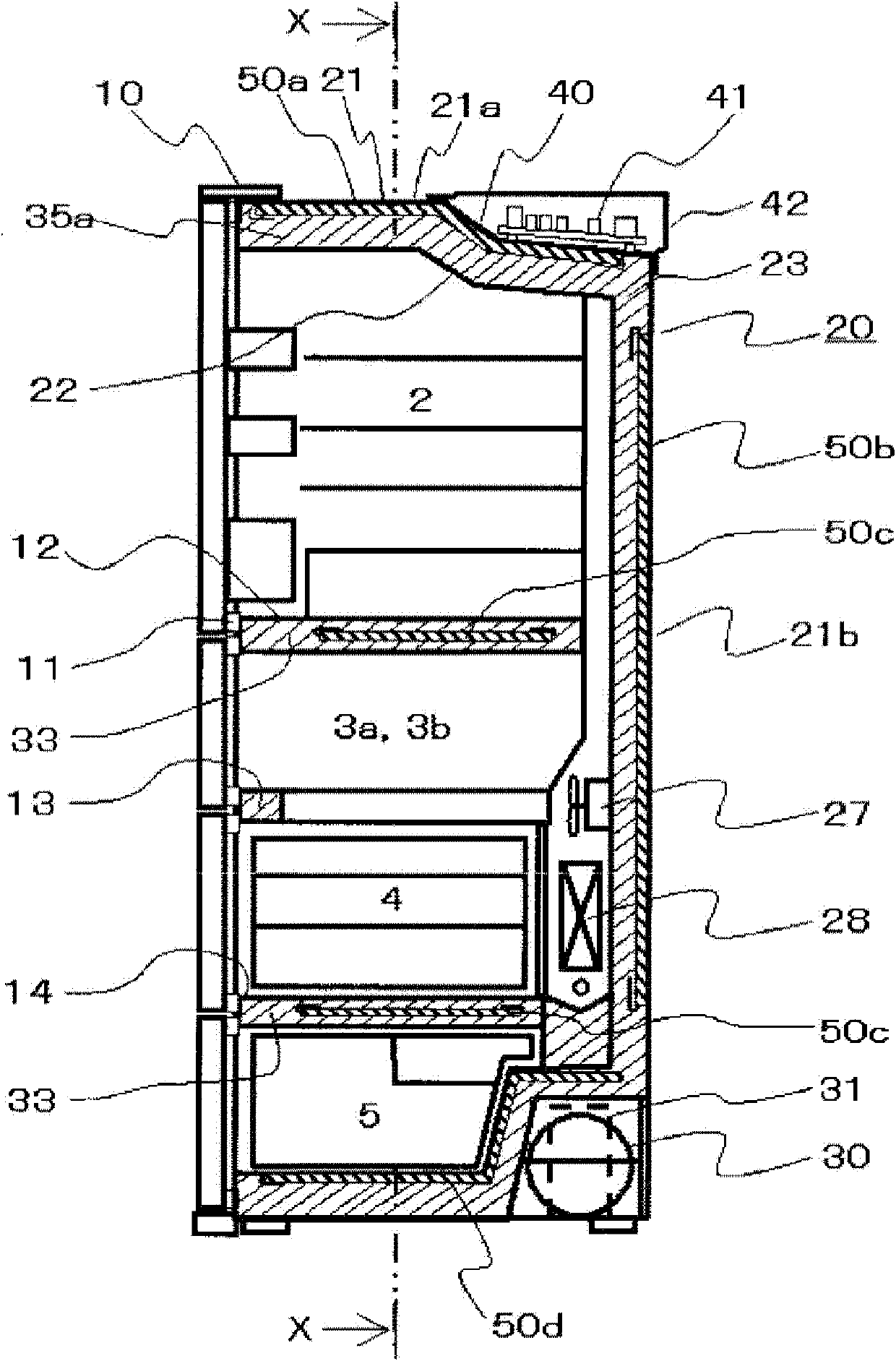

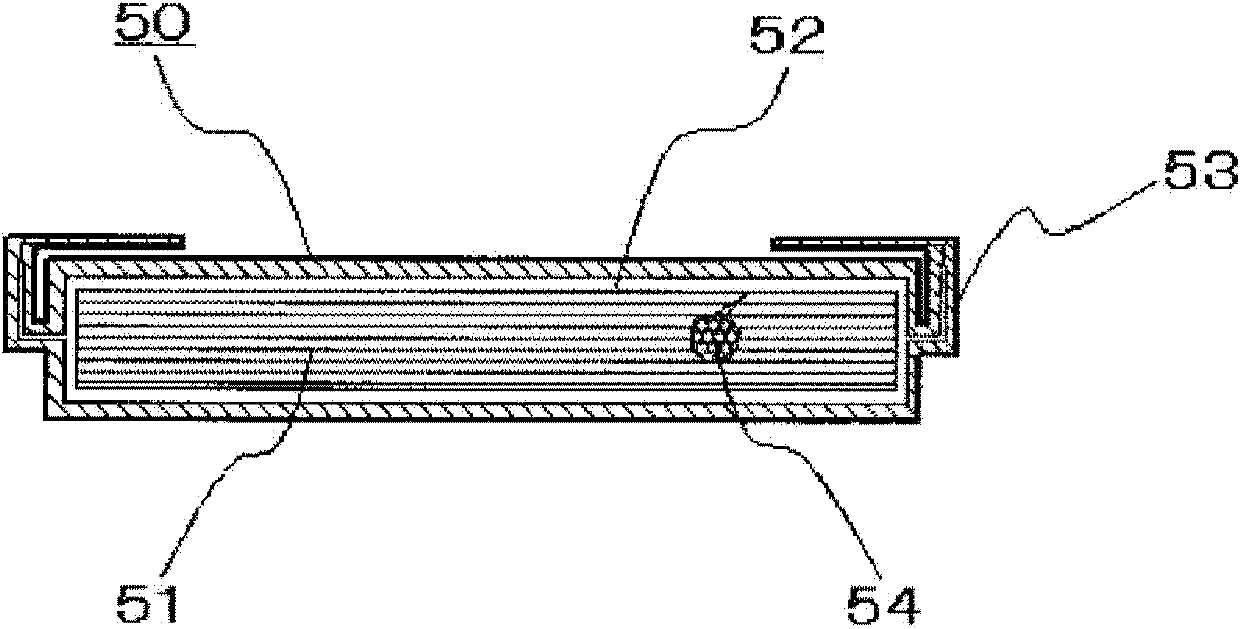

[0041] Regarding the refrigerator provided with the vacuum insulation material according to the first embodiment of the present invention, refer to Figure 1 to Figure 7 Be explained. figure 1 It is a front view of the appearance of the refrigerator provided with the vacuum insulation material concerning 1st Embodiment of this invention. figure 2 It is a longitudinal sectional view of the refrigerator provided with the vacuum insulation material concerning 1st Embodiment, and is figure 1 Sectional view of line A-A. image 3 It is a cross-sectional view of the vacuum insulation material used in the first embodiment.

[0042] in addition, Figure 4 It is a longitudinal sectional view of the refrigerator provided with the vacuum insulation material concerning 1st Embodiment, and is figure 2 Cross-sectional view of the X-X line. Figure 5 It is a cross-sectional view of the refrigerator provided with the vacuum heat insulating material according to the first embodiment, an...

no. 2 approach

[0072] Next, refer to Figure 8 The structure of the separator in the refrigerator provided with the vacuum heat insulating material concerning 2nd Embodiment of this invention is demonstrated. Figure 8 It is a figure which shows the arrangement|positioning of the spacer with respect to an outer case and the foaming direction of foamed polyurethane concerning 2nd Embodiment. In the second embodiment, due to the figure 1 , image 3 , Figure 4 , Figure 5 and Figure 7 Since the structure of the refrigerator provided with the vacuum insulation material concerning 1st Embodiment demonstrated is the same, this structure is used.

[0073] exist Figure 8 In the spacer 71 used in the second embodiment, the same material as the foamed polyurethane 23 is molded into a predetermined shape with a molding die not shown in advance, so it has the same structure as the spacer 70 of the first embodiment. The joining surfaces 71a, 71b formed of continuous planar surfaces may be provi...

no. 3 approach

[0085] Next, refer to Figure 11 and Figure 12 The shape of the spacer according to the third embodiment, the relational structure and arrangement structure of the heat radiation pipes will be described below. Such as Figure 11 As shown in (a), the spacer 77 used in the third embodiment is provided with a relief groove so that the heat dissipation pipe 90 does not abut against the spacer 70 of the first embodiment. Such as Figure 11 As shown in (b), the relief groove 77c for the heat radiation pipe 90 is provided on the joint surface 77b so that the spacer 77 can be provided on the projection surface of the heat radiation pipe 90 fixed by the aluminum tape 91 on the inner surface of the outer case 21e. . The width and height of the groove 77c are set to be larger than the diameter of the heat radiation pipe 90 so that the polyurethane foam 23 flows between the heat radiation pipe 23 and the groove 77c and fills it up. As for the heat radiation pipe 90, as shown in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com