System and method for cooling high-carbon steel wire rod after rolling

A technology of cooling system and cooling method, applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of uneven cooling of wire rod 2, large fluctuations in microstructure, high proportion of upper bainite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

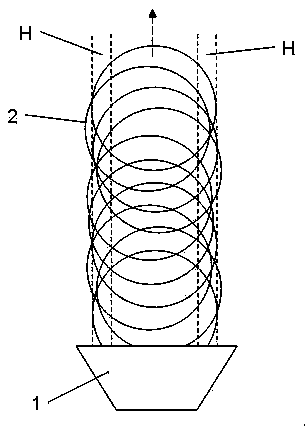

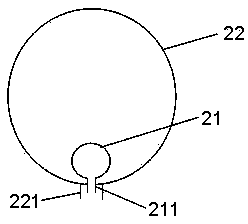

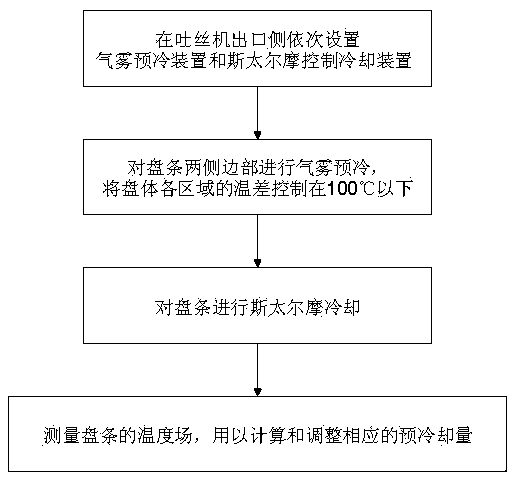

[0026] see figure 2 As shown, the post-rolling cooling system for the high carbon steel wire rod of the present invention includes a Stellmor control cooling device 10 arranged on the outlet side of the laying head 1, so as to cool the wire rod 1 entering into the area of the Stellmor control cooling device 10. Cooling (its structure and cooling principle are basically the same as those of traditional Stellmor cooling, and will not be repeated here). The cooling system also includes an aerosol pre-cooling device 20, which is arranged on the roller table 3 between the laying head 1 and the first cooling fan 11 of the Stellmor control cooling device 10. The overlapping area H of the strip 2 is sprayed with aerosol for cooling, and a forced convection steam film is formed on the surface of the wire rod in the overlapping area H, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com