Olefin polymerization method

An olefin polymerization and olefin technology, applied in the field of olefin polymerization, can solve the problems of low catalytic activity and low efficiency, and achieve the effect of stable mesoporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

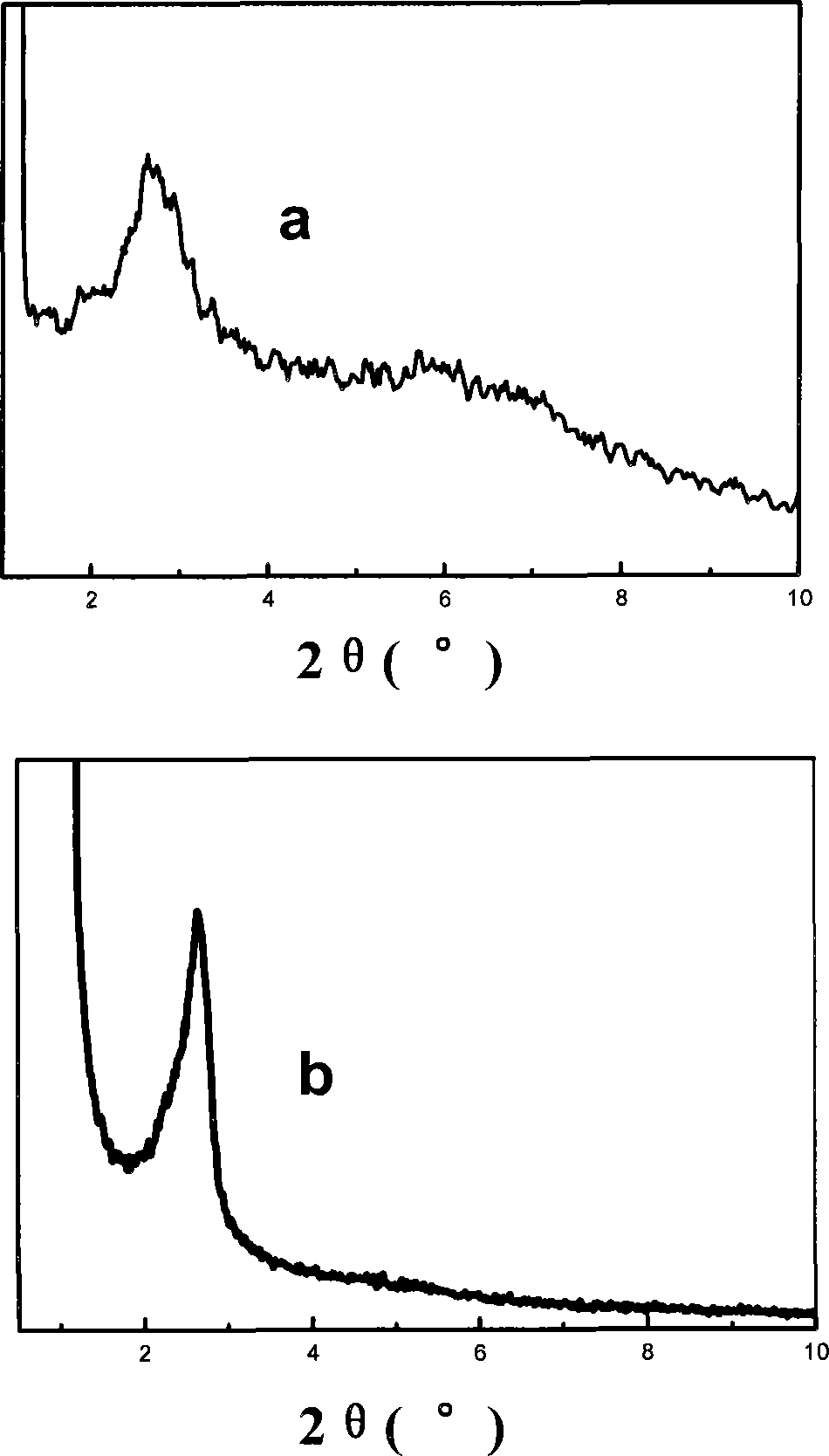

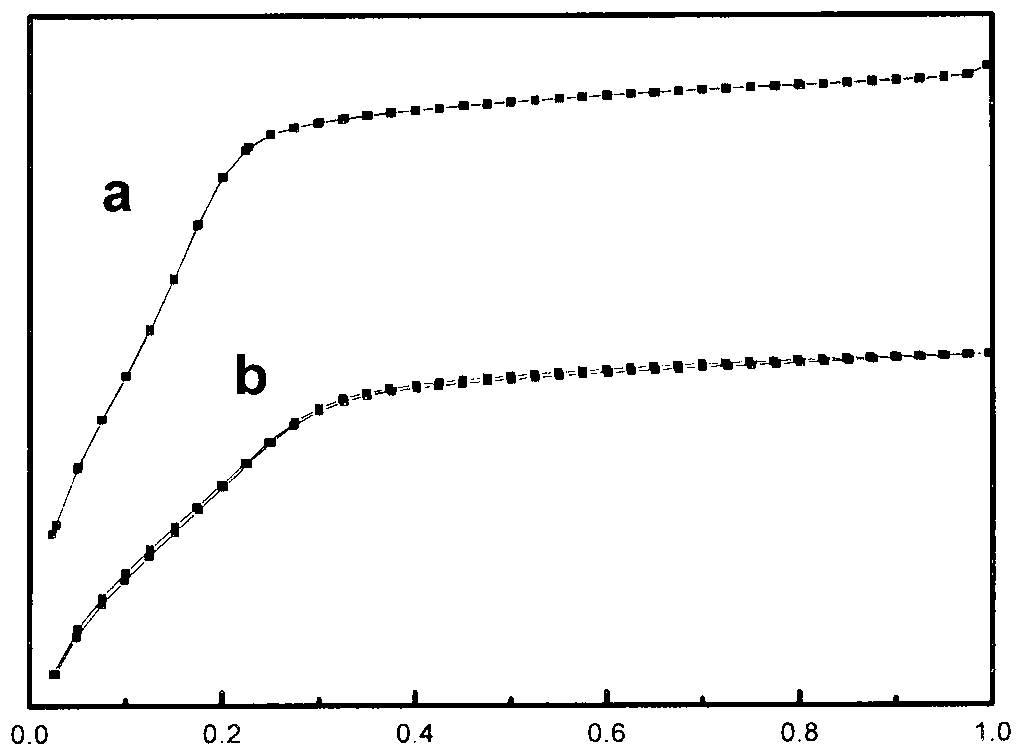

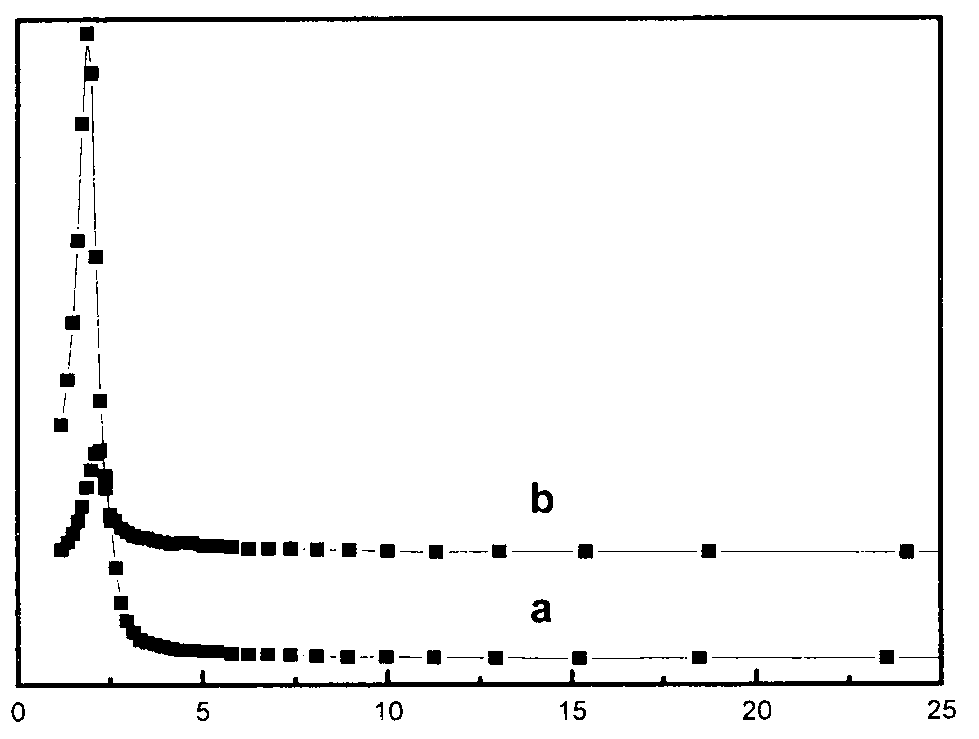

[0064] Mix 1.5 grams of CTAB (cetyltrimethylammonium bromide), 1.5 mL of polyethylene glycol octylphenyl ether (Triton-X100) with 29.6 grams of concentrated hydrochloric acid (37% by weight) Contact with a hydrochloric acid solution of 75 grams of water, stir at 40°C until CTAB is completely dissolved, add 4.35 grams of tetraethyl orthosilicate to the above solution, stir at 40°C for 15 minutes, and stand at 40°C for 24 hours, After filtering, washing and drying, calcining at 600°C for 24 hours, the carrier JKQ was obtained;

[0065] Under nitrogen protection, JKQ was calcined at 400°C for 10 hours to remove hydroxyl groups and residual moisture, thereby obtaining thermally activated JKQ;

[0066] 0.3407 g of activated JKQ was transferred to a 250 ml glass reactor fully replaced by nitrogen, and 20 ml of refined toluene (refluxing via sodium for 24 hours) and 0.4 g of methylalumoxane (purchased from Albemarle, USA) were added , and stirred at 50 °C for 4 hours. After the rea...

Embodiment 1

[0078] This example serves to illustrate the olefin polymerization process according to the present invention.

[0079] In a 2-liter stainless steel autoclave, replace three times each with nitrogen and ethylene, then add 200 ml of hexane, raise the temperature of the kettle to 80 ° C, then add 800 ml of hexane, and add 2 ml of hexane with the addition of hexane 1 mole / liter of triethylaluminum (TEA, purchased from Zhejiang Furuide Chemical Co., Ltd.) hexane solution, then add 43.3 mg of JKQ-BU, feed ethylene to raise the pressure to 1.0MPa and maintain it at 1.0MPa, React at 70°C for 1 hour. Obtain 213 grams of polyethylene particle powder, the bulk density (BD) of this polyethylene particle powder is 0.306g / ml, melt index MI 2.16 = 0.026 g / 10 min. It was determined by calculation that the efficiency of the catalyst was 4919g PE / gcat h (ie, 1.1×10 9 g PE / (mol Zr h)).

Embodiment 2

[0081] This example serves to illustrate the olefin polymerization process according to the present invention.

[0082] In a 2-liter stainless steel autoclave, replace three times each with nitrogen and ethylene, then add 200 ml of hexane, raise the temperature of the kettle to 80 ° C, then add 800 ml of hexane, and add 2 ml of hexane with the addition of hexane 1 mole / liter triethylaluminum (TEA) hexane solution and 10 milliliters of hexene, then add 40.3 milligrams of JKQ-BU, feed ethylene to raise the pressure to 1.0 MPa and maintain it at 1.0 MPa, react at 70 ° C for 1 Hour. 269 grams of polymer were obtained with a bulk density (BD) of 0.321 g / ml and a melt index MI 2.16 = 0.384 g / 10 min. It is determined by calculation that the efficiency of the catalyst is 6675g PE / gcat h (ie, 1.5×10 9 g PE / (mol Zr h)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com