Method for producing gasoline and diesel oil through hydrogenation of coal tar

A technology for coal tar and gasoline, used in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of high operating pressure and large investment, and achieve the effect of improving cetane number and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

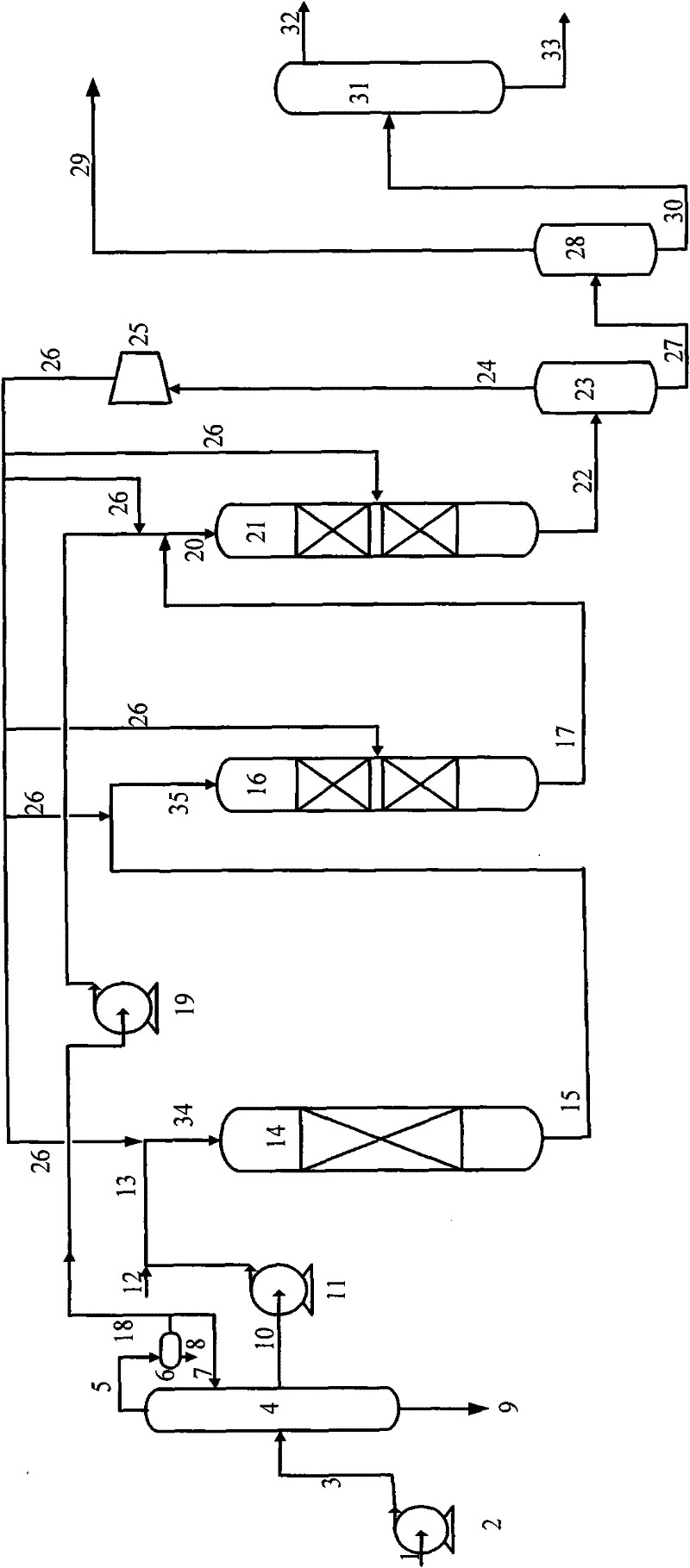

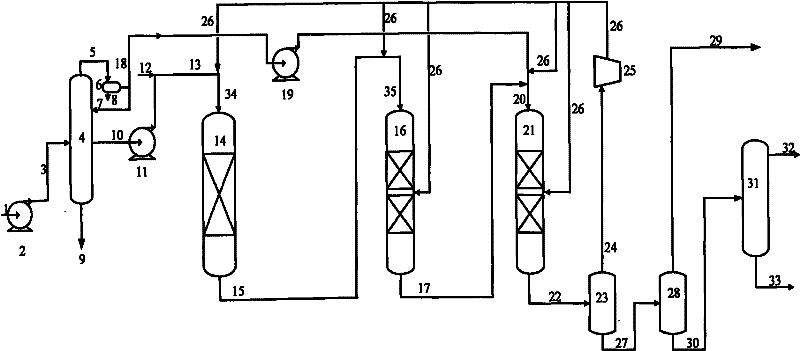

Method used

Image

Examples

Embodiment 1

[0044] The distillate at 200°C to 375°C is contacted with the catalyst A in the hydrogenation protection reactor and the catalyst B in the first hydrofining reactor to react, and the reaction effluent is denoted as D. The light fraction <200°C is mixed with the effluent D and hydrogen and then enters the second hydrofining reactor, and contacts the catalyst G and the catalyst C in the second hydrofinishing reactor for reaction. The reaction effluent is separated and fractionated to obtain gasoline fraction and diesel fraction. The specific reaction conditions are shown in Table 3, the properties of gasoline products are shown in Table 4, and the properties of diesel products are shown in Table 5.

[0045] It can be seen from Table 4 that the density of the product gasoline fraction is 0.7885g / cm 3 , The sulfur content is less than 10μg / g, and the research octane number is 87.0, which is 8 units lower than the light fraction in coal tar feedstock. It can be seen from Table 5 that...

Embodiment 2

[0047] The distillate at 200°C to 375°C is contacted with the hydrogenation protection catalyst A and the catalyst B in the first hydrogenation reactor to react, and the reaction effluent is denoted as E. The light fraction <200°C is mixed with the effluent E and hydrogen and then enters the second hydrogenation reactor, and contacts the catalyst G and the catalyst C in the second hydrogenation reactor for reaction. The reaction effluent is separated and fractionated to obtain gasoline fraction and diesel fraction. The specific reaction conditions are shown in Table 3, the properties of gasoline products are shown in Table 4, and the properties of diesel products are shown in Table 5.

[0048] It can be seen from Table 4 that the density of the product gasoline fraction is 0.7902g / cm 3 , The sulfur content is less than 10μg / g, and the research octane number is 88.5, which is 6.5 units lower than the light fraction in coal tar feedstock. It can be seen from Table 5 that the cetan...

Embodiment 3

[0050] The distillate at 200°C to 375°C is contacted with the hydrogenation protection catalyst A and the catalyst B in the first hydrogenation reactor for reaction, and the reaction effluent is denoted as F. The light fraction <200°C is mixed with the liquid effluent F and hydrogen and then enters the second hydrogenation reactor, and contacts the catalyst G and the catalyst C in the second hydrogenation reactor for reaction. The reaction effluent is separated and fractionated to obtain gasoline fraction and diesel fraction. The specific reaction conditions are shown in Table 3, the properties of gasoline products are shown in Table 4, and the properties of diesel products are shown in Table 5.

[0051] It can be seen from Table 4 that the density of the product gasoline fraction is 0.7855g / cm 3 , The sulfur content is less than 10μg / g, and the research octane number is 86.5, which is a decrease of 8.5 units compared with the light fraction in the coal tar feedstock. It can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com